Sound absorption structure of volute and volute air inlet of noise reduction centrifugal fan

A technology of centrifugal fan and air inlet, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of difficult calculation and limited noise reduction effect, so as to achieve safe and reliable structure, obvious sound absorption effect, and unique Secondary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the examples, but the implementation scope of the present invention is not limited only to the following examples.

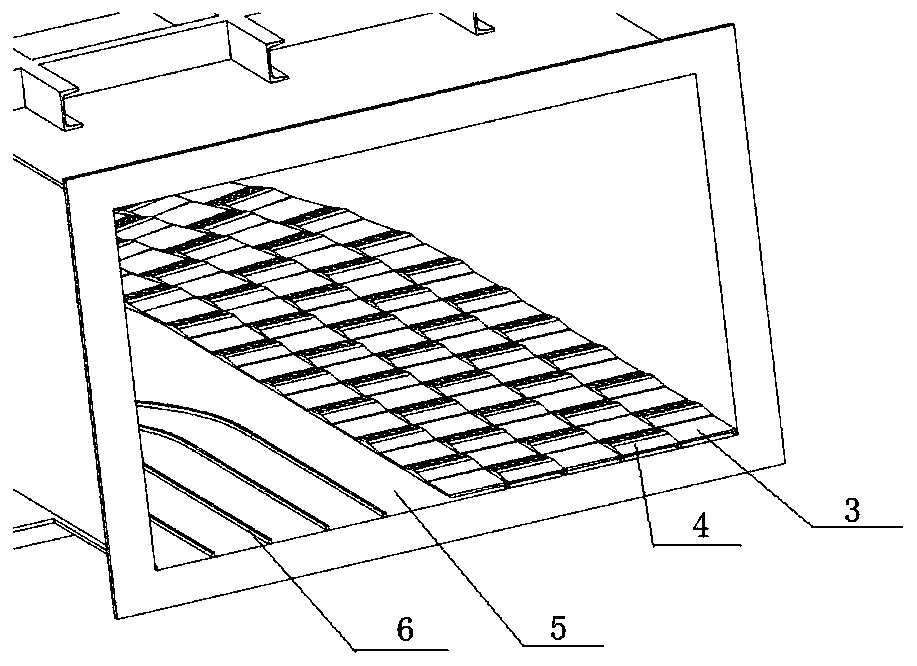

[0037] Such as Figure 1-Figure 12 As shown, a sound-absorbing structure of a noise-reducing centrifugal fan volute and its air inlet, the sound-absorbing plate is fixed on the volute side plate 5 through the mounting plate 6, and a sound-absorbing plate is formed between the sound-absorbing plate and the volute side plate 5 Anechoic chamber; several web sound-absorbing panels 2 are evenly arranged horizontally and vertically on the volute web 1; several obliquely arranged arc-shaped guides are arranged on the arc-shaped side wall of the air inlet 7 of the volute piece.

[0038] Such as Figure 1-Figure 3 As shown, the sound-absorbing panels include two types: the sound-absorbing panel I4 and the sound-absorbing panel II3, and the sound-absorbing panel I4 and the sound-absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com