Electric auxiliary heating type waste gas recirculation mixer

A technology of exhaust gas recirculation and auxiliary heating, applied in the direction of exhaust gas recirculation, machine/engine, engine components, etc., can solve the problems of clogging the EGR mixer, poor ventilation, unable to start or stall the engine, etc. Reliability, the effect of preventing failure to start or stall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

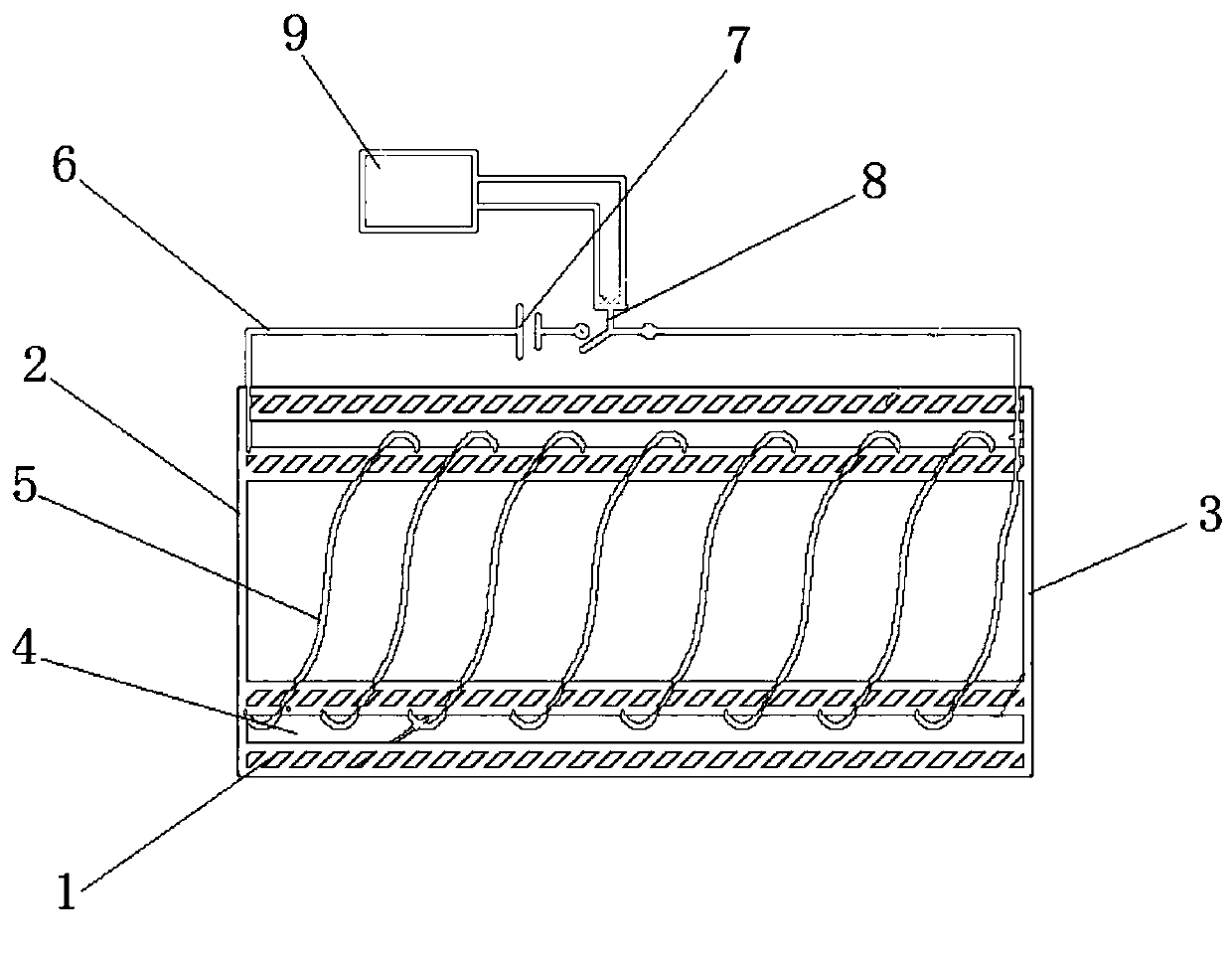

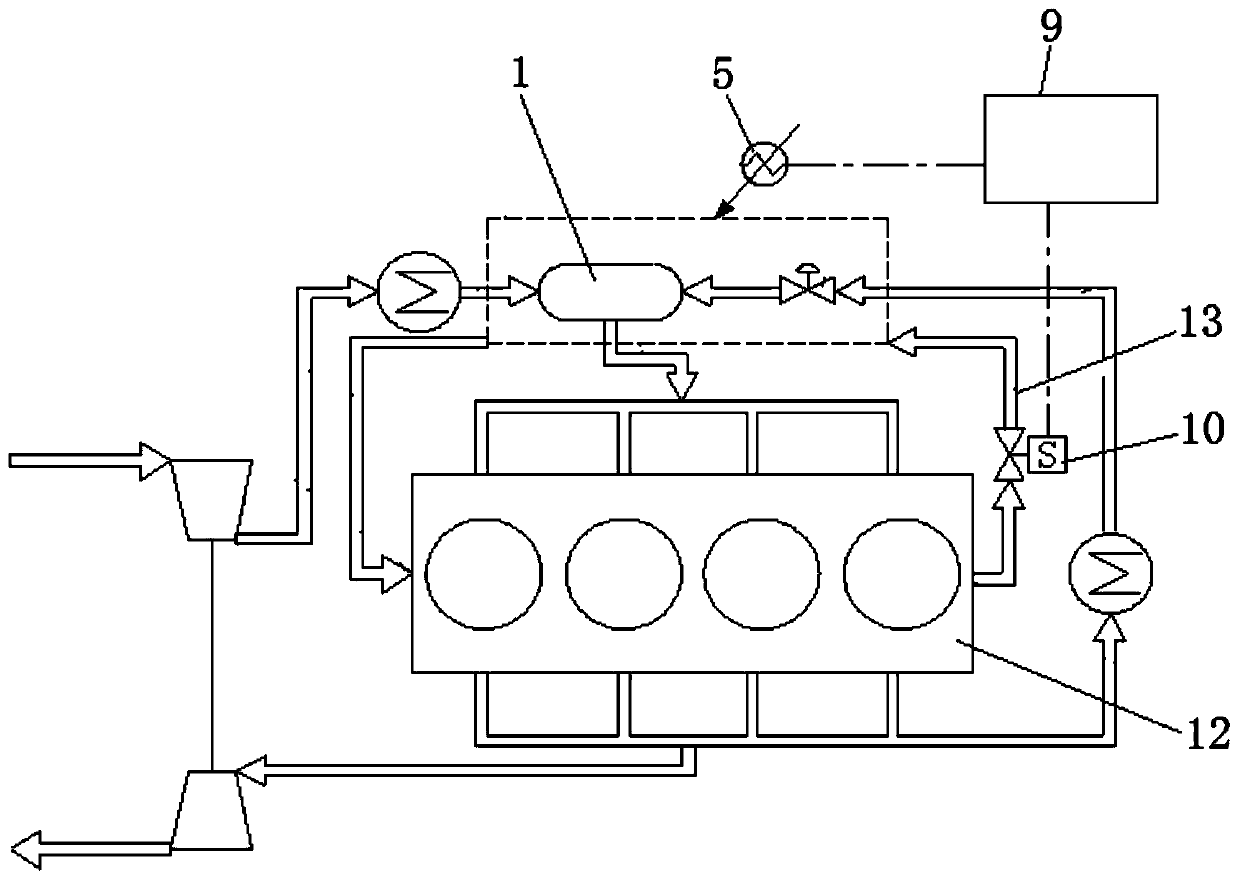

[0014] The specific embodiment of the present invention is like this: as figure 1 As shown, an electric auxiliary heating exhaust gas recirculation mixer includes a mixer body 1, an air inlet 2 and an air outlet 3 are arranged on the mixer body 1, and a surrounding mixer is arranged on the shell of the mixer body 1 The mixing cavity of the main body 1 is provided with an accommodating cavity 4, and the wall of the accommodating cavity 4 is provided with an electric heating device 5 arranged around the mixing cavity of the mixer body 1, and the electric heating device 5 is an electric heating ring. In the electrified auxiliary heating exhaust gas recirculation (EGR) mixer, the electric heating device 5 is used to conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com