Friction plug rivet welding system based on programmable logic controller (PLC)

A welding system and welding machinery technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., to achieve the effect of ensuring welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below according to the accompanying drawings:

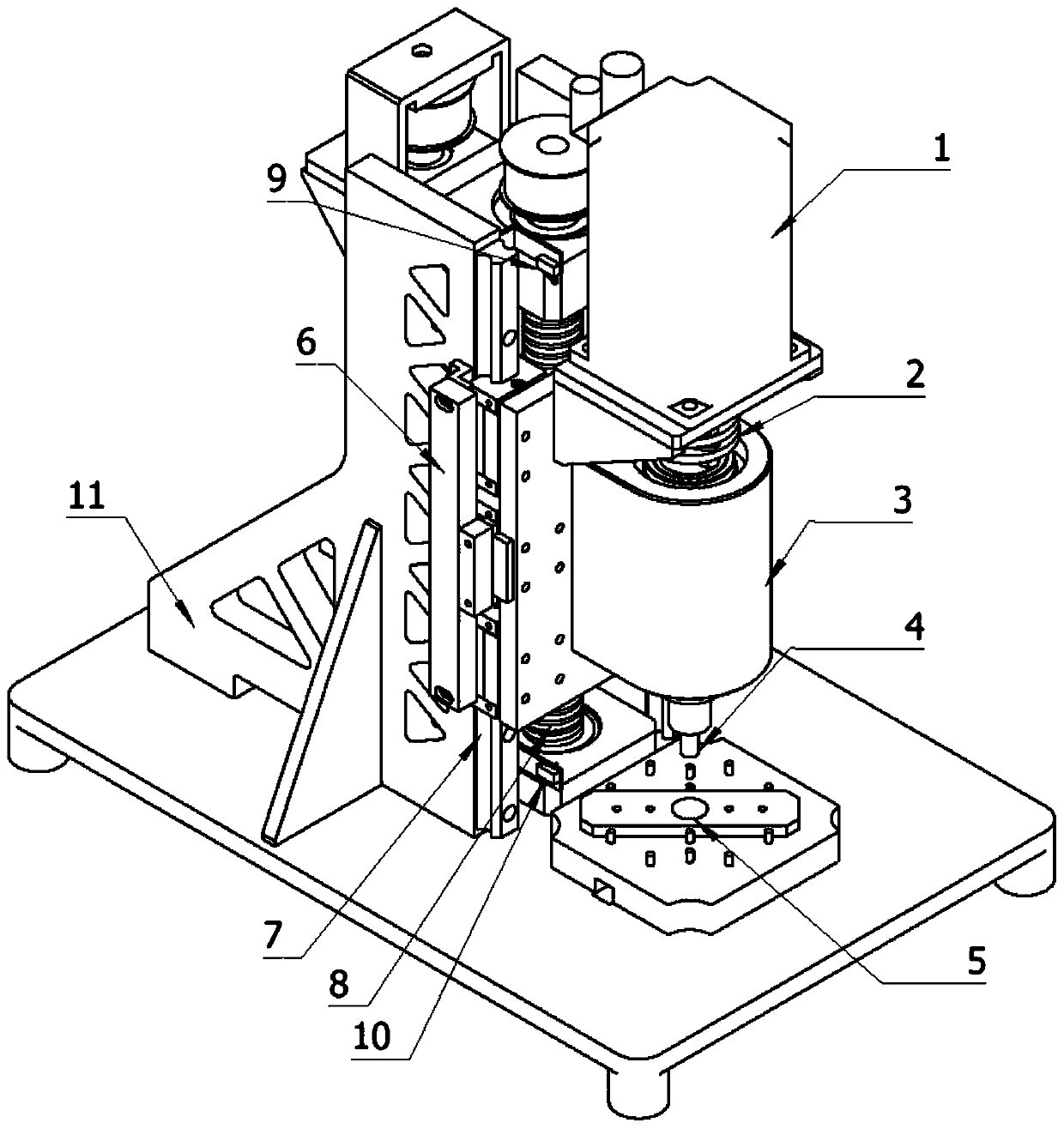

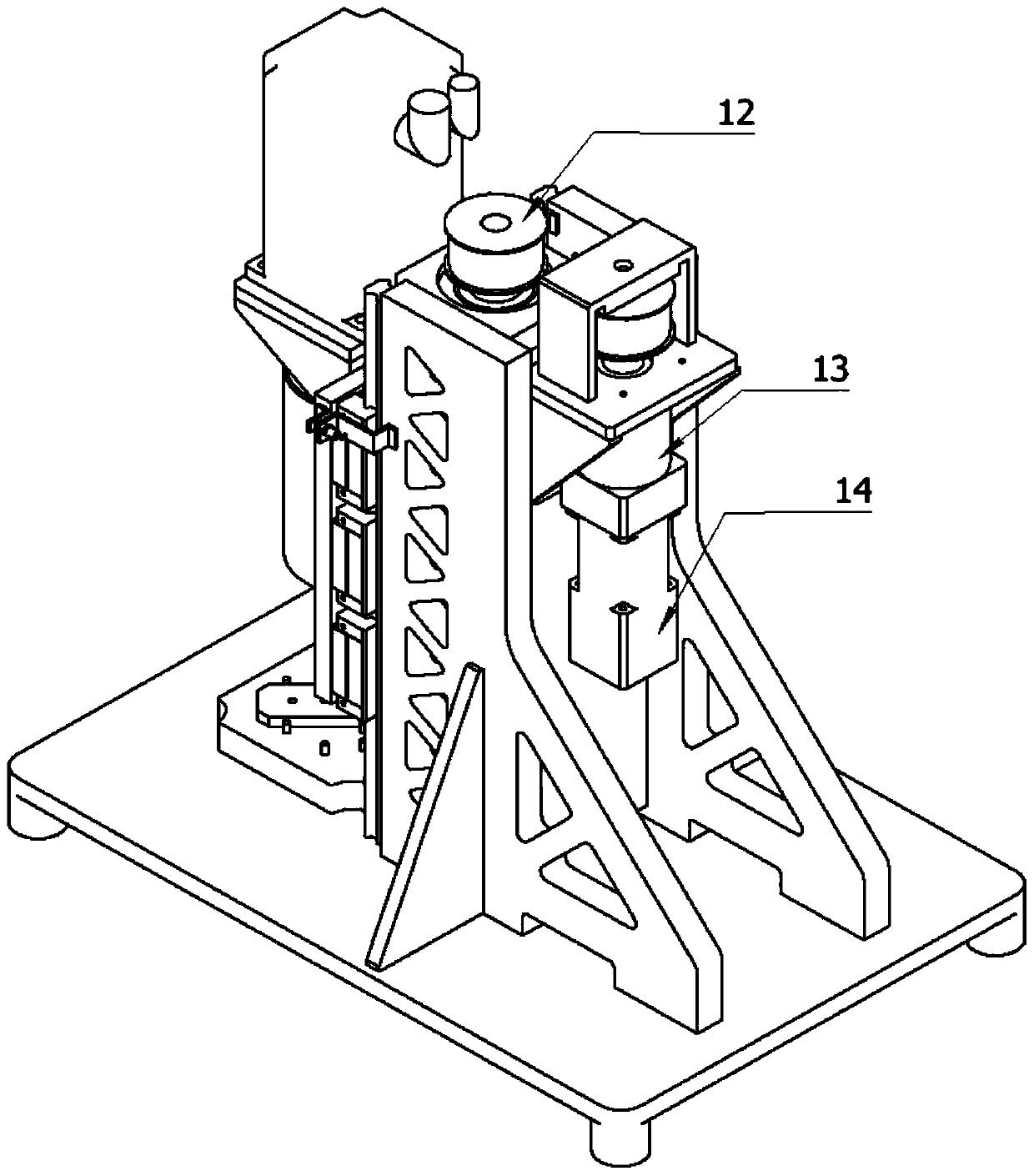

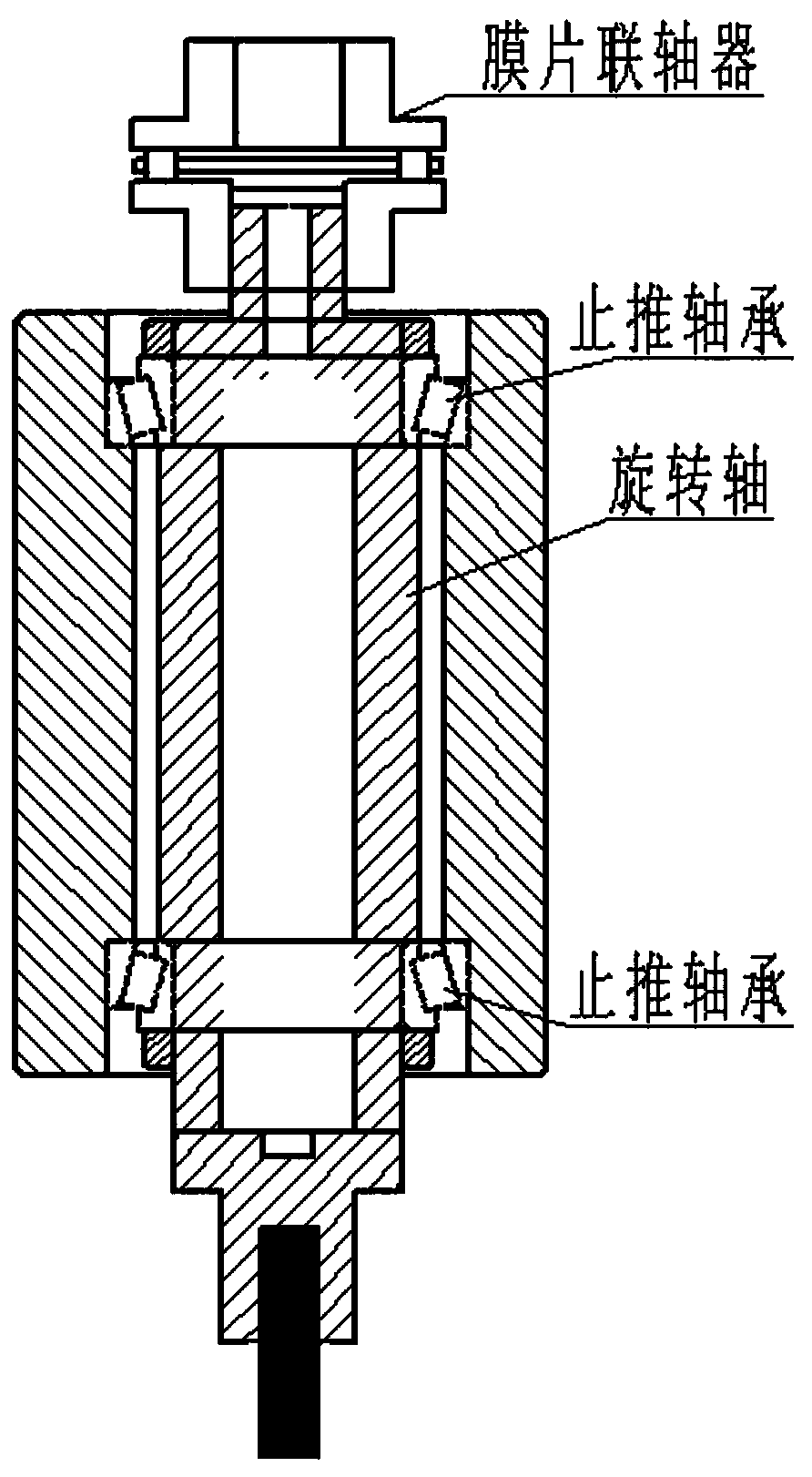

[0017] figure 1 , figure 2 It is a schematic diagram of the overall structure of the plug riveting welding mechanism. The plug riveting welding mechanism includes a rotating motor 1, a diaphragm coupling 2, a rotating shaft 3, a rivet head 4, a spoke pressure sensor 5, a grating ruler 6, a linear guide 7, and a ball Lead screw 8, upper limit switch 9, lower limit switch 10, frame 11, synchronous pulley 12, planetary reducer 13, stroke motor 14. The rotating motor 1 is fixed on the frame 11, and the rotating shaft 3 is connected with the rotating motor 1 through the diaphragm coupling 2 to realize the rotating movement of the equipment. The stroke motor 14 is connected with the planetary reducer 13, and drives the rotation of the ball screw 8 through the synchronous pulley 12, so as to realize the axial movement of the equipment. The rivet head 4 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com