Flip LED chip

An LED chip and flip-chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of light inconcentration, chip dispersion, poor light efficiency, etc., to eliminate the impact, improve the light output efficiency, and reduce the voltage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

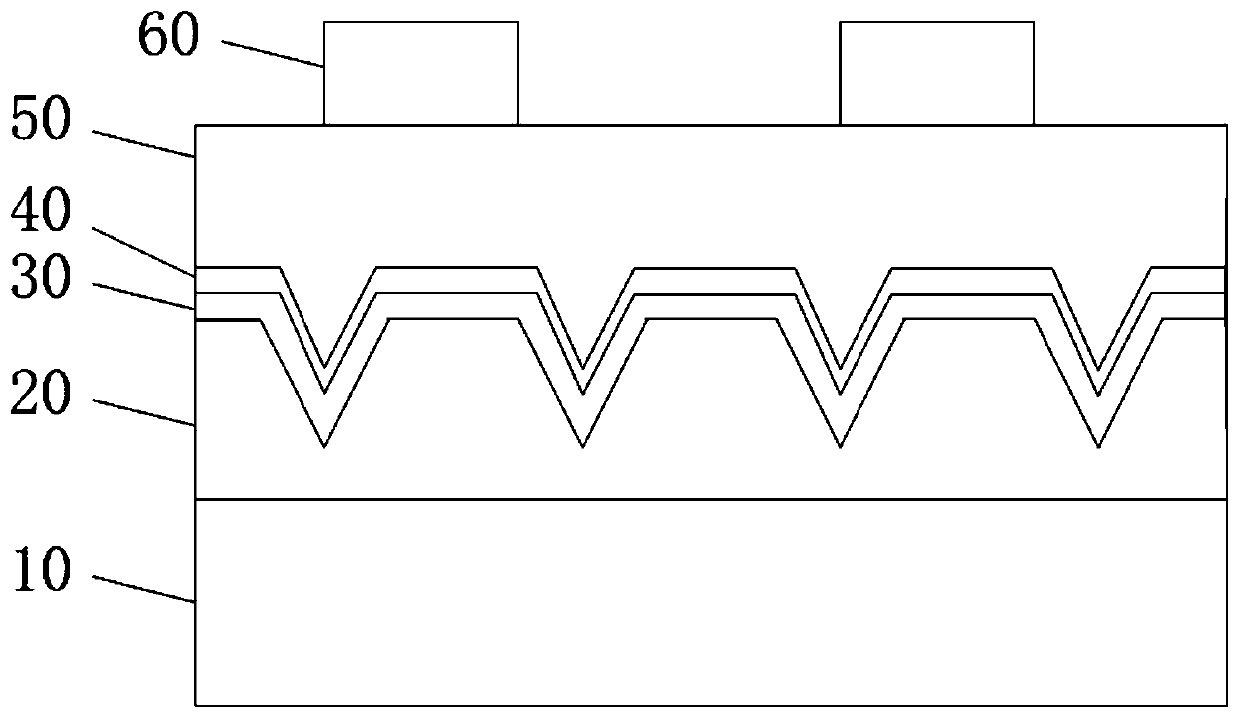

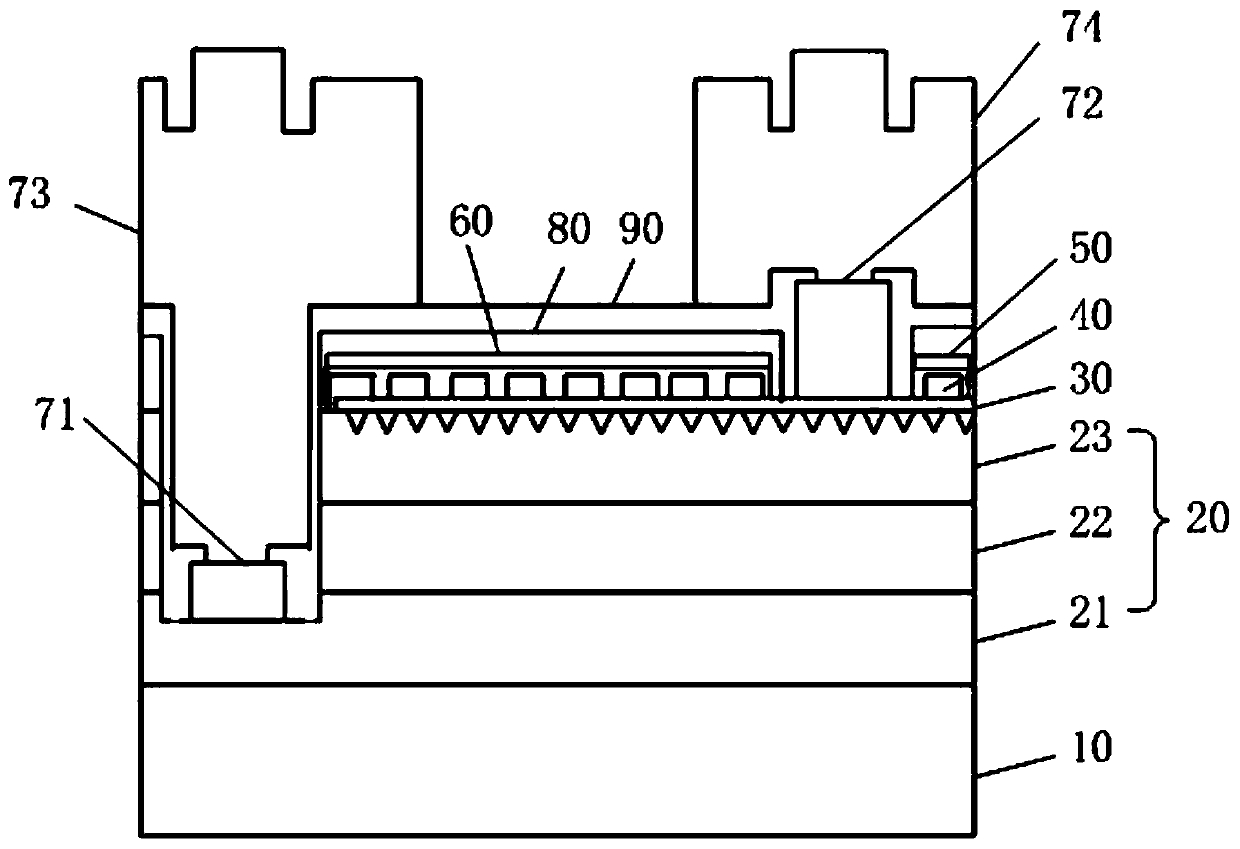

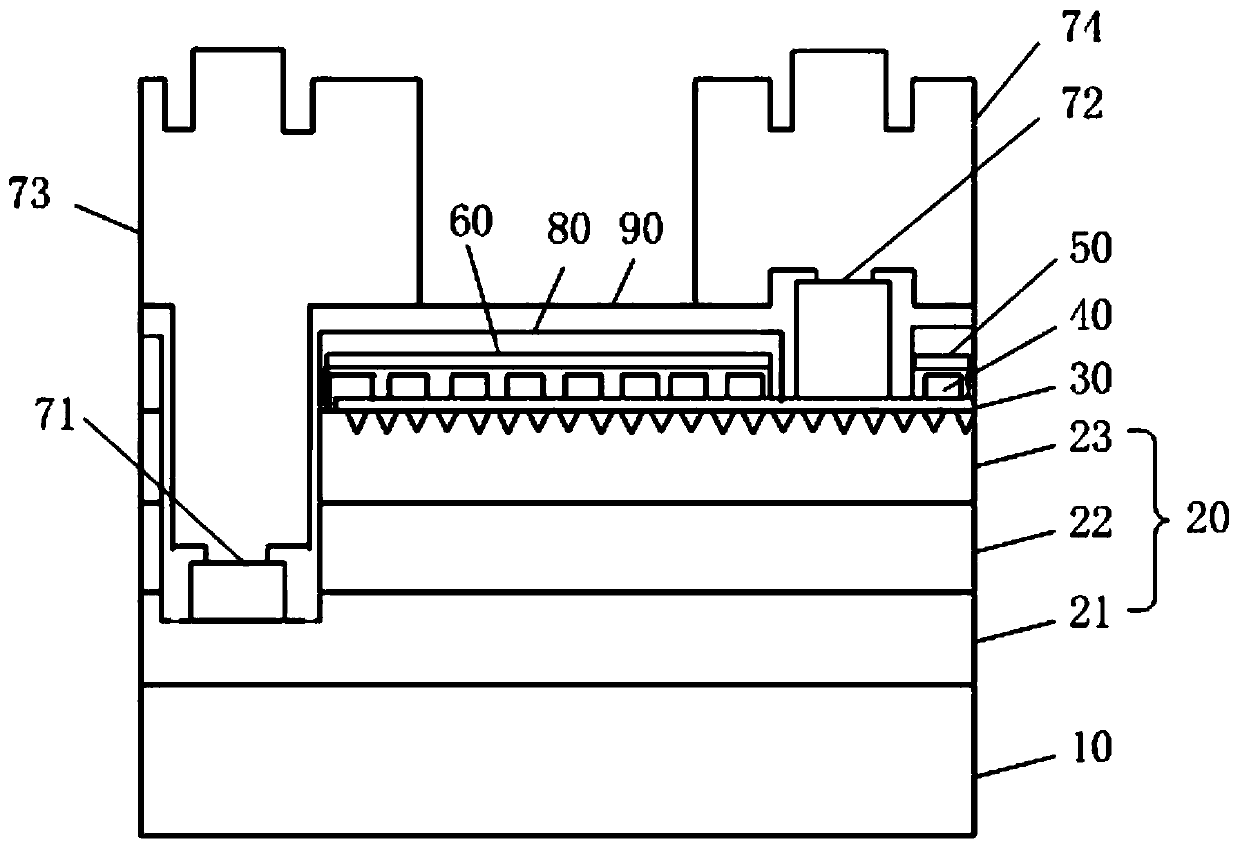

Embodiment 1

[0048] A flip-chip LED chip, comprising a substrate, an epitaxial layer, a transparent conductive layer, a leveling layer, an adhesive layer, a reflective layer, and an electrode structure, the epitaxial layer is arranged on the substrate, and the transparent conductive layer is arranged on On the epitaxial layer, the filling layer is arranged on the transparent conductive layer to fill up the concave-convex structure of the epitaxial layer, the filling layer is provided with a plurality of first holes, the adhesive layer is arranged on the filling layer and It is filled into the first hole to form a conductive connection with the transparent conductive layer. The reflective layer is arranged on the adhesive layer to form full mirror reflection. The filling layer is made of silicon oxide, and the adhesive layer is made of ITO. The reflective layer is made of silver, the thickness of the filling layer is 300nm, the thickness of the adhesive layer is 10nm, the thickness of the re...

Embodiment 2

[0050] A flip-chip LED chip, comprising a substrate, an epitaxial layer, a transparent conductive layer, a leveling layer, an adhesive layer, a reflective layer, and an electrode structure, the epitaxial layer is arranged on the substrate, and the transparent conductive layer is arranged on On the epitaxial layer, the filling layer is arranged on the transparent conductive layer to fill up the concave-convex structure of the epitaxial layer, the filling layer is provided with a plurality of first holes, the adhesive layer is arranged on the filling layer and Fill in the first hole to form a conductive connection with the transparent conductive layer, the reflective layer is arranged on the adhesive layer to form a total mirror reflection, the filling layer is made of aluminum oxide, and the adhesive layer is made of Ni / Made of Au oxide, the reflective layer is made of silver, the thickness of the filling layer is 500nm, the thickness of the adhesion layer is 30nm, the thicknes...

Embodiment 3

[0052] A flip-chip LED chip, comprising a substrate, an epitaxial layer, a transparent conductive layer, a leveling layer, an adhesive layer, a reflective layer, and an electrode structure, the epitaxial layer is arranged on the substrate, and the transparent conductive layer is arranged on On the epitaxial layer, the filling layer is arranged on the transparent conductive layer to fill up the concave-convex structure of the epitaxial layer, the filling layer is provided with a plurality of first holes, the adhesive layer is arranged on the filling layer and It is filled into the first hole to form a conductive connection with the transparent conductive layer. The reflective layer is arranged on the adhesive layer to form a total mirror reflection. The filling layer is made of magnesium difluoride, and the adhesive layer is made of Made of AzO, the reflective layer is made of silver, the thickness of the filling layer is 700nm, the thickness of the adhesive layer is 60nm, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com