Automatic recognition method for large-volume concrete mold-entering temperature

A large-volume concrete and mold-entry temperature technology, which is applied to thermometers, applications of thermometers, and parts of thermometers, can solve problems such as time-consuming and labor-intensive problems, and achieve the effects of reducing workload, improving construction efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as figure 1 As shown, a method for automatically identifying the mold entry temperature of large-volume concrete provided in this embodiment includes the following steps:

[0042] In the first step, after the mass concrete reinforcement binding and formwork are completed, the M A temperature measuring device is fixed in the steel mesh.

[0043] The temperature measuring device is used to measure the temperature of mass concrete, and several monitoring points are usually set up, and several temperature measuring devices are set along the concrete depth direction at each monitoring point.

[0044] In the second step, the temperature measuring device is connected to the data acquisition device, and the data acquisition device collects the temperature data of the temperature sensor according to a preset frequency, and transmits the data to the server.

[0045] The data acquisition device may be a plc controller or an intelligent instrument, etc., but of course it is ...

Embodiment 2

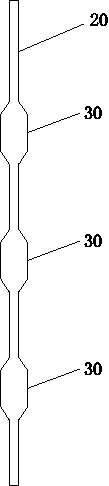

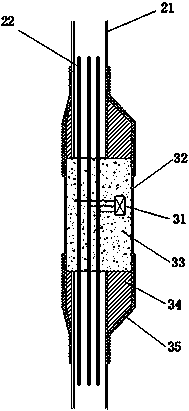

[0063] This embodiment is a preferred implementation of embodiment one, combining figure 2 and image 3 As shown, the temperature measuring device adopts a series temperature measuring device, and each of the series temperature measuring devices includes a number of temperature measuring devices 30 packaged on the data line 20 connected in series, and the temperature measuring device 30 includes a temperature Sensor 31 , thin-walled steel sleeve 32 , rubber pad 34 and heat shrinkable sleeve 35 . The data line 20 includes three core wires 22 encapsulated in the sheath 21, two of which are power supply lines and one is a data collection line, and the core wires of the data lines located at the temperature measuring device are parallel to the short horizontal bar. The sheath 21 of the data line 20 in the packaging part is disconnected, the three pins of the temperature sensor 31 are respectively connected to the three core wires 22 of the data line 20, and the thin-walled steel...

Embodiment 3

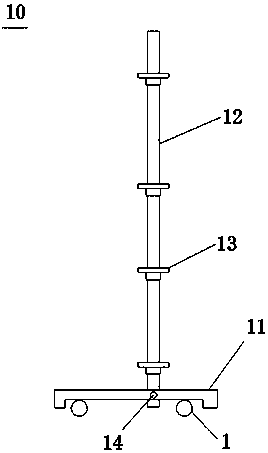

[0067] This embodiment is a preferred implementation of Embodiment 2. The series temperature measuring device is fixed on the temperature measuring device bracket. The device bracket is vertically placed in the reinforcement mesh according to the preset interval, and the support base is supported on the bottom reinforcement, and the vertical rod is fixed on the upper reinforcement.

[0068] combine Figure 4 to Figure 6 As shown, the temperature measuring device bracket 10 includes a support base 11 and a vertical bar 12 arranged on the support base 11, the support base 11 is hinged to the bottom end of the vertical bar 12, and the hinge point is close to one end of the support base 11; the vertical bar 12 is provided with several short crossbars 13 for fixing the series temperature measuring device at intervals.

[0069] Further, the two ends of the support base 11 are provided with downward convex edges, which can make the support base 11 better supported on the steel bar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com