Method and system for realizing simultaneous ship loading and unloading of LNG receiving station

A technology for a receiving station and a transport ship, which is applied in the field of simultaneous loading and unloading of LNG receiving stations, can solve the problems of large BOG generation, large pressure loss, unstable pressure control, etc. The effect of reducing the amount of flash evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

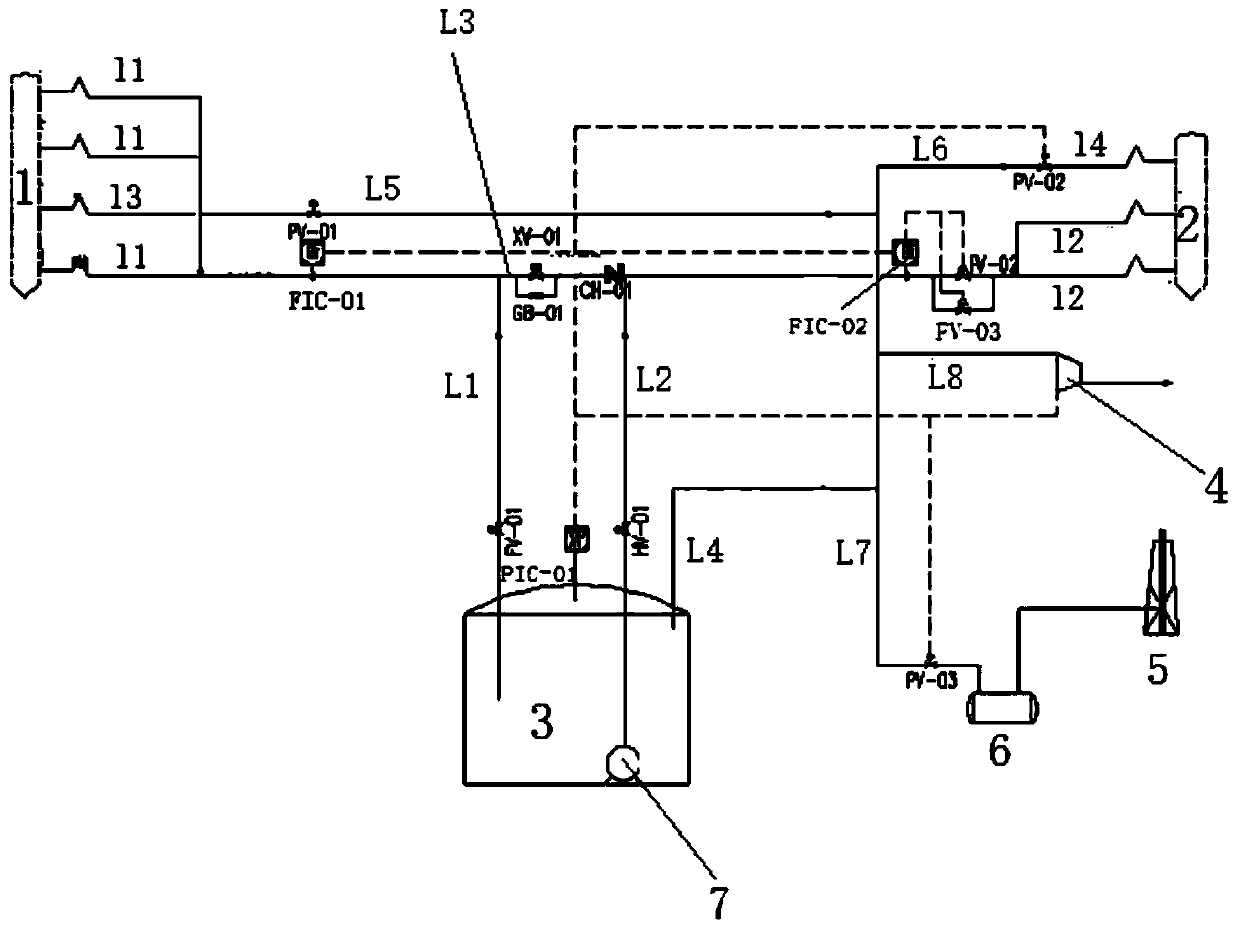

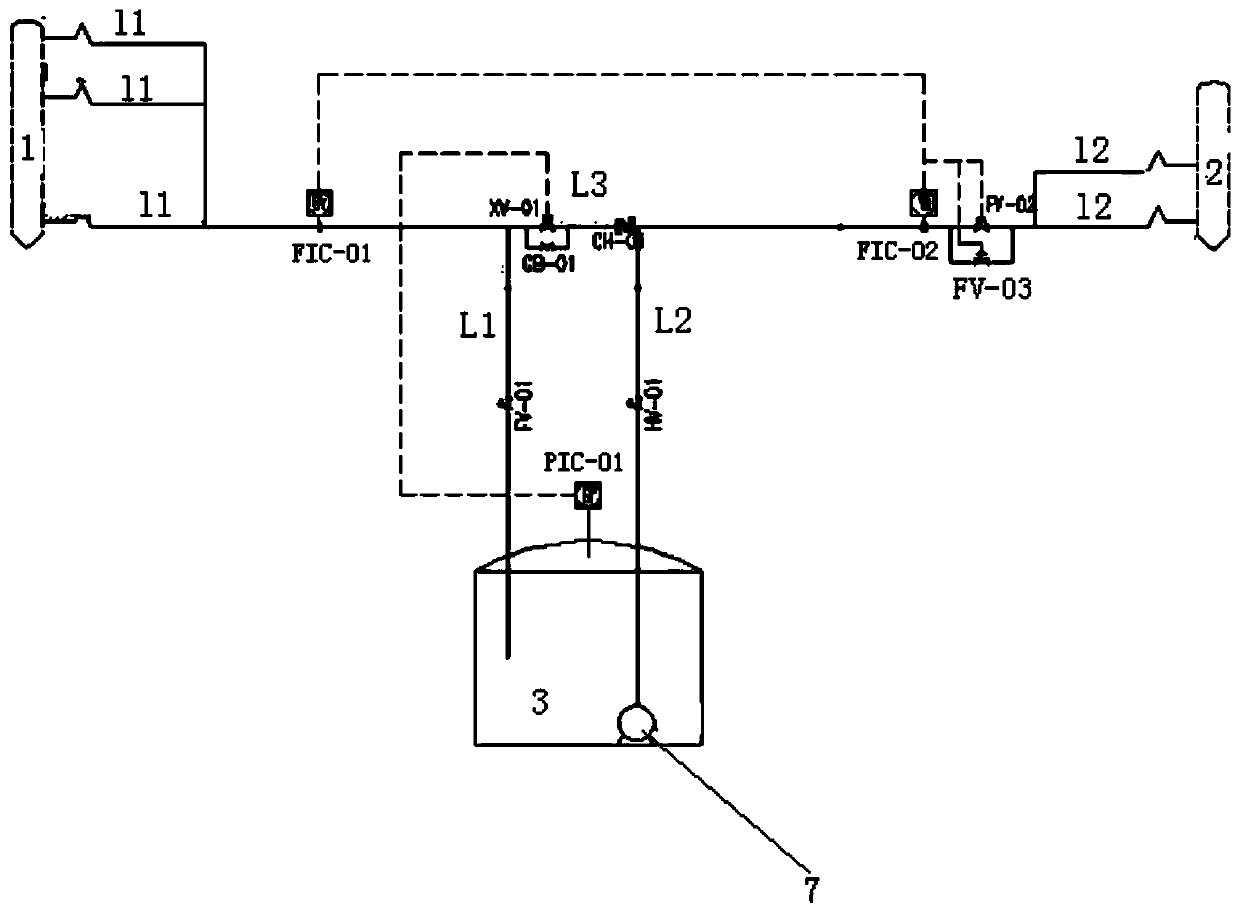

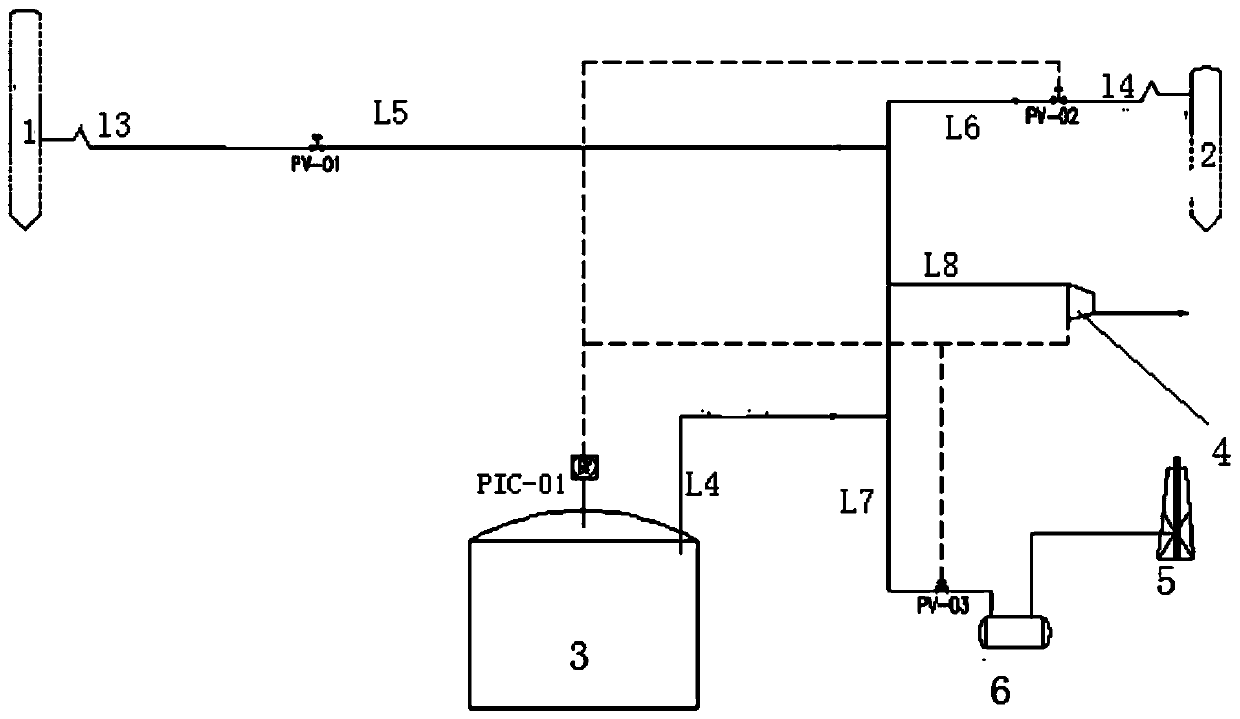

[0062] (1) An LNG carrier (as the first LNG carrier, 270,000 m 3 LNG) arrived at the unloading dock, the second LNG carrier (40,000 m 3 ) After arriving at the loading dock, check the total discharge flow (12000m 3 ), the LNG receiving station operator, according to the pre-signed agreement with the LNG shipper, sets the return flow rate (3200m 3 ), through the transfer pump in the first LNG transportation, transported from the unloading liquid phase arm to the unloading main pipe, and sent to the LNG loading pipeline via the over-berthing pipeline, and installed in the first flowmeter FIC-01 of the unloading main pipe Through the flow rate set by the LNG receiving station engineer, the opening of the flow regulating valve FV-02 on the LNG loading pipeline is controlled to stabilize the LNG flow entering the second LNG carrier at the set value (3200m 3 ), the remaining LNG is transported to the LNG storage tank;

[0063] (2) The boil-off gas (35kPag) replaced after LNG enters the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com