Automatic balance steel dispensing assembly process for lipstick cartridge

An assembly process and a core bundle technology, which are applied in the directions of material gluing, devices for coating liquid on the surface, connecting components, etc., can solve the problems of complex structure, difficult for users to bring hand feeling, low level of automation of production process, etc. Strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

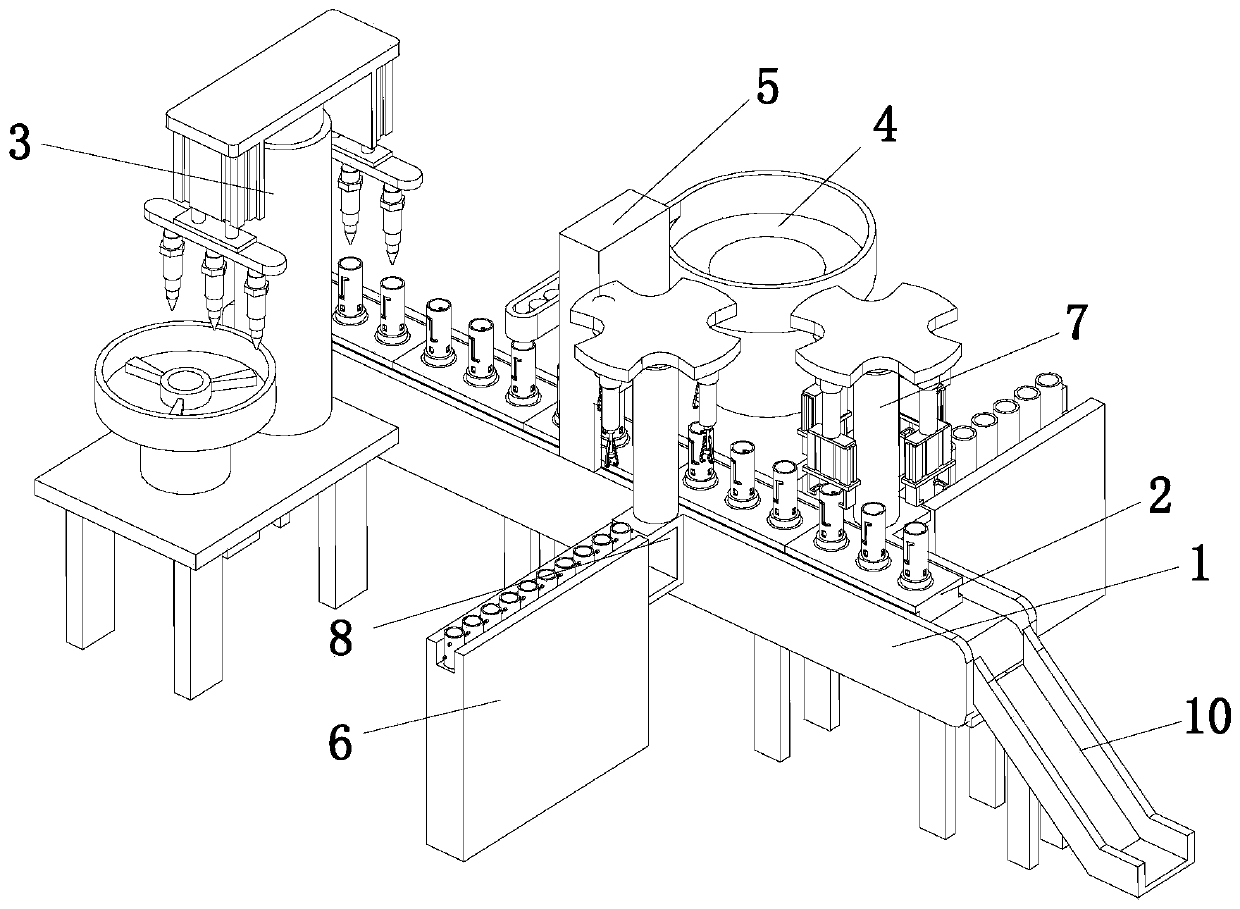

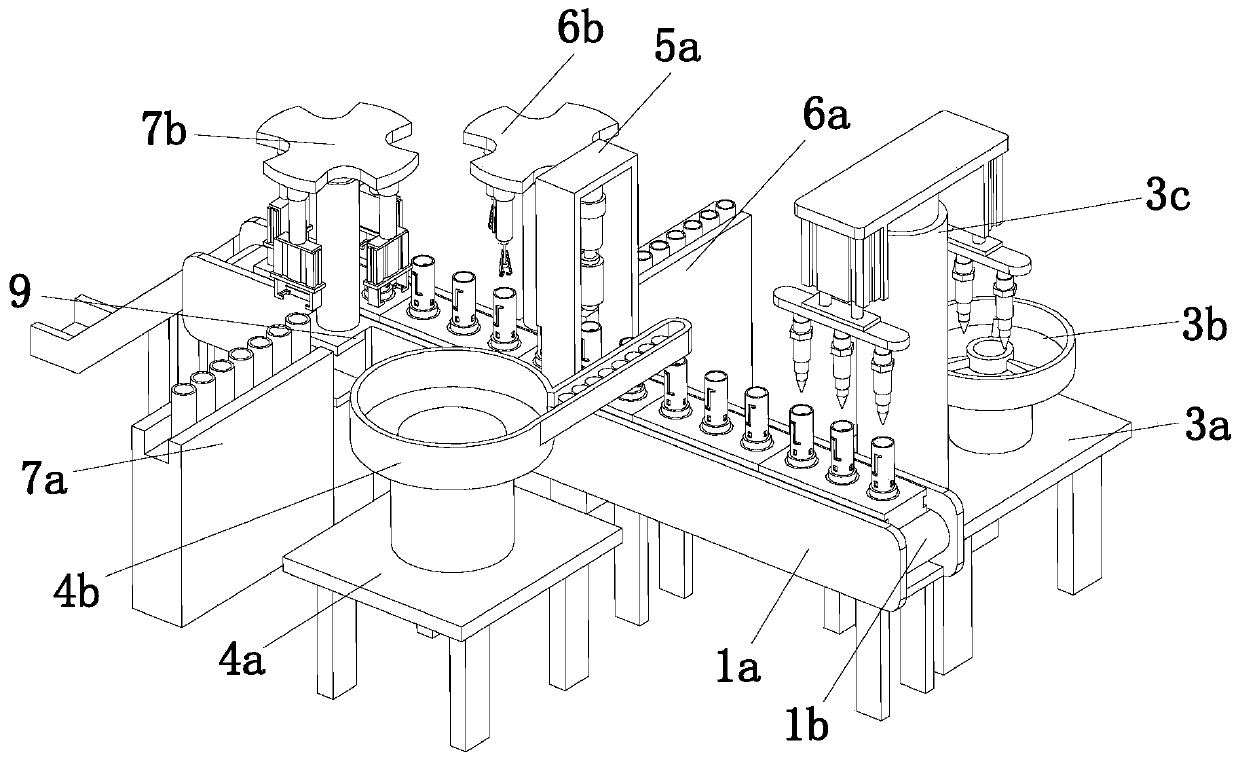

[0036] refer to Figure 1 to Figure 9 A kind of assembly process of automatic weighting iron dispensing for the center beam core of lipstick shown includes the following steps:

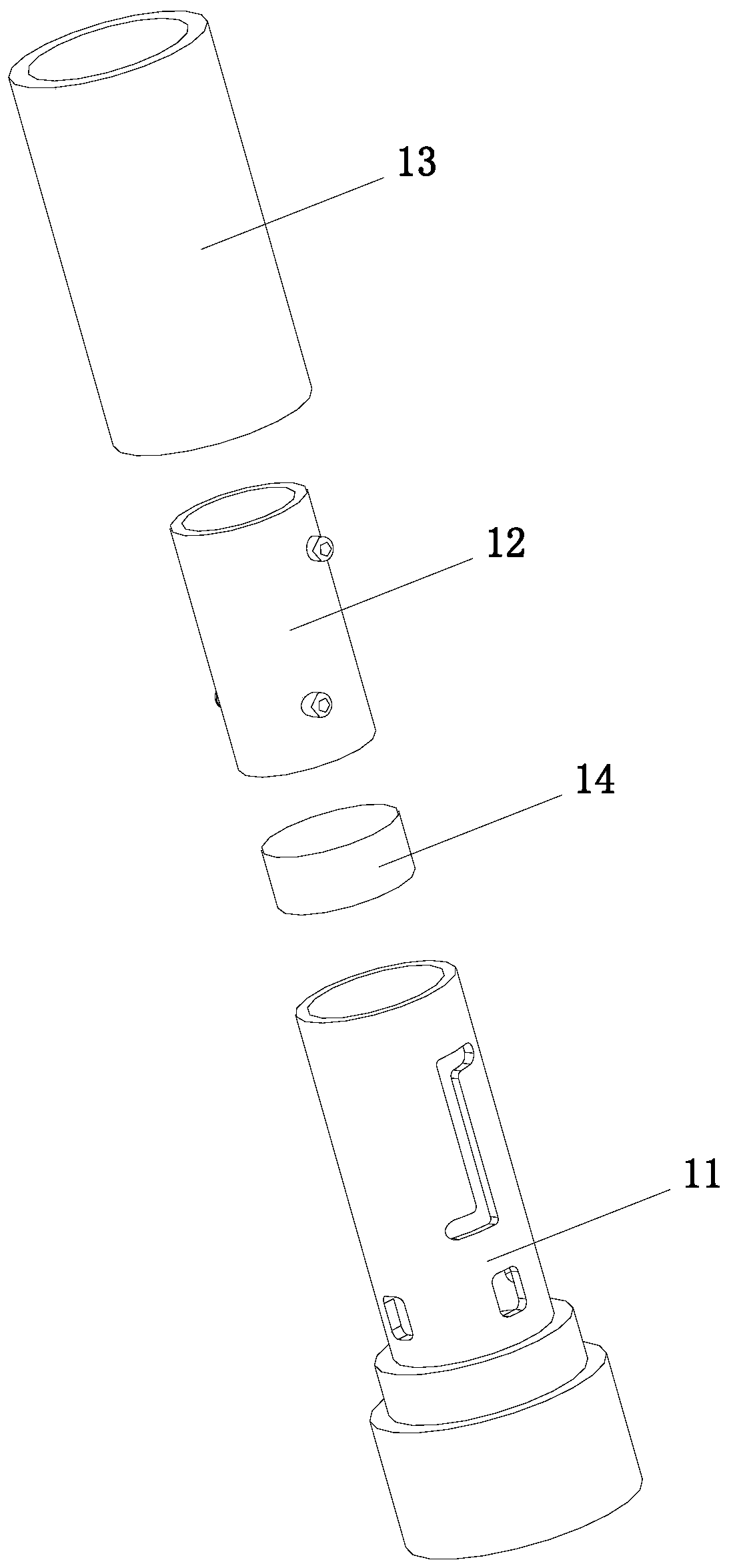

[0037] Step 1. Automatic feeding of the middle beam: set up a conveying device 1 for conveying the middle beam 11, and the top of the conveying device 1 is provided with several tightly fitted mold bases 2 for placing the middle beam 11, along the The conveying direction of the conveying device 1 is sequentially provided with a dispensing device 3 for dispensing glue to the middle bundle 11, a feeding device 4 for conveying the weighted iron 14 to the inside of the middle bundle 11, and a pressing device for performing the pressing process. Device 5, the first assembling device 6 for assembling the beads 12 into the middle beam 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com