Low-inlet-pressure and high-pressurization-capacity combined electric pump

A technology of inlet pressure and high boost pressure, which is applied to engine components, machines/engines, liquid fuel feeders, etc., and can solve the problem of complex engine fuel supply control system, complex fuel supply regulation system, pipeline layout and other structural volume occupations. Large space and other problems, to achieve the effect of reducing control complexity and cost, reducing system volume and weight space, and reducing overall volume and installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

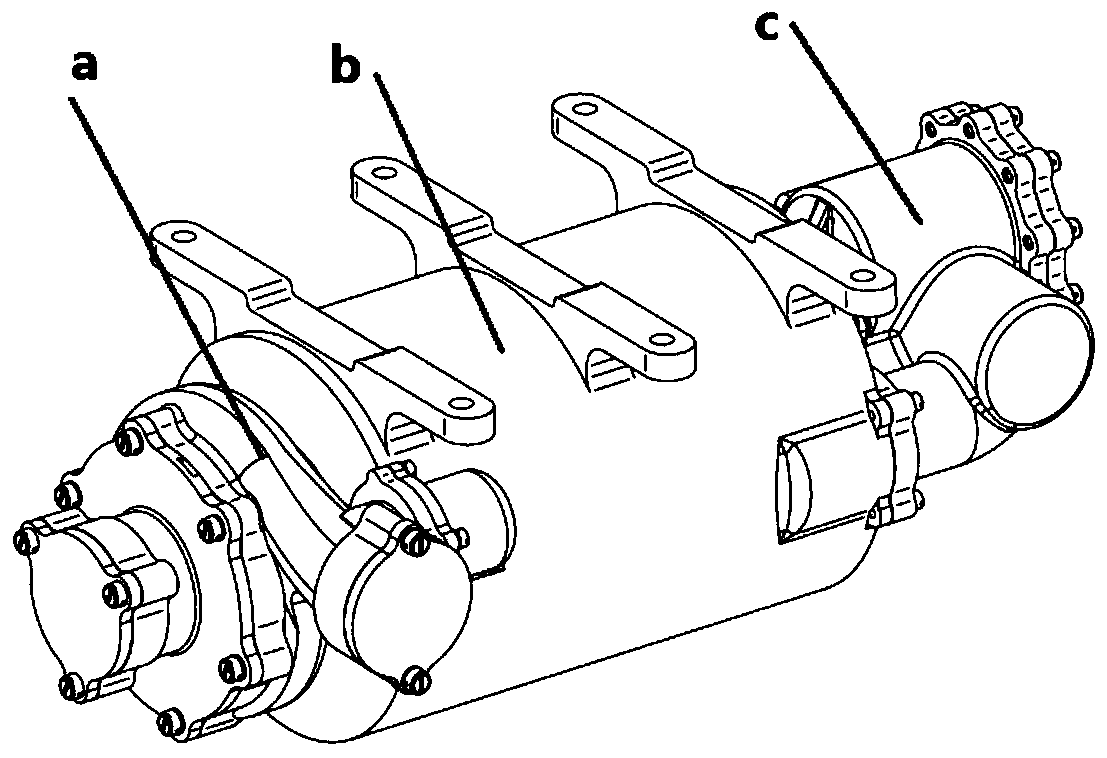

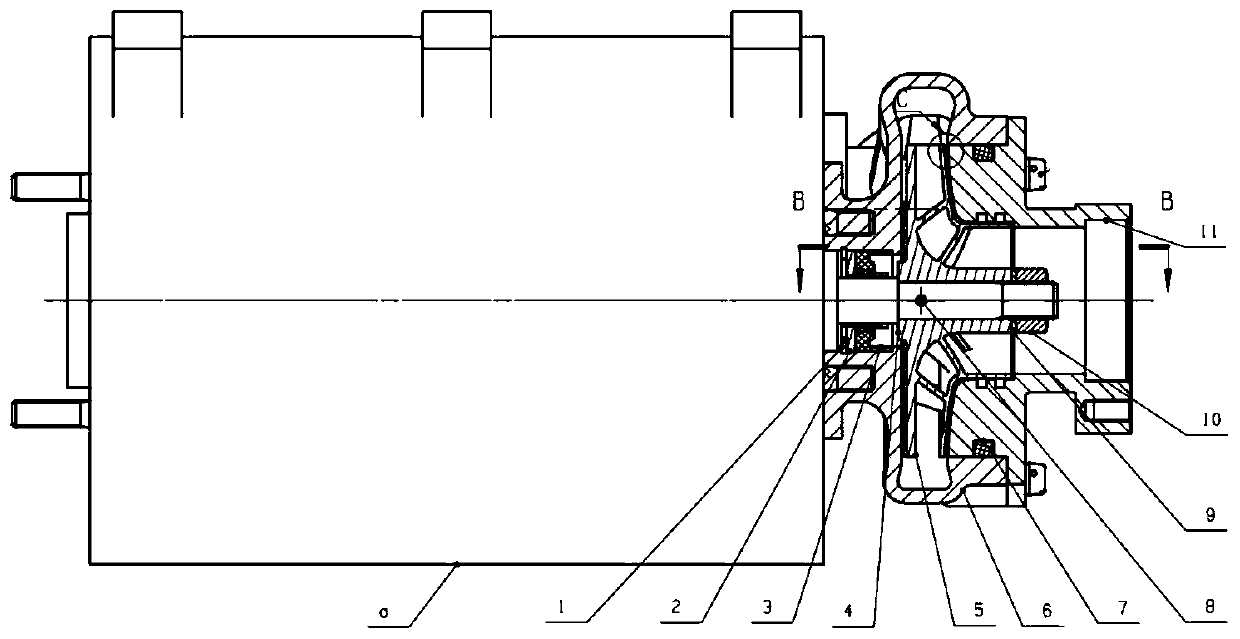

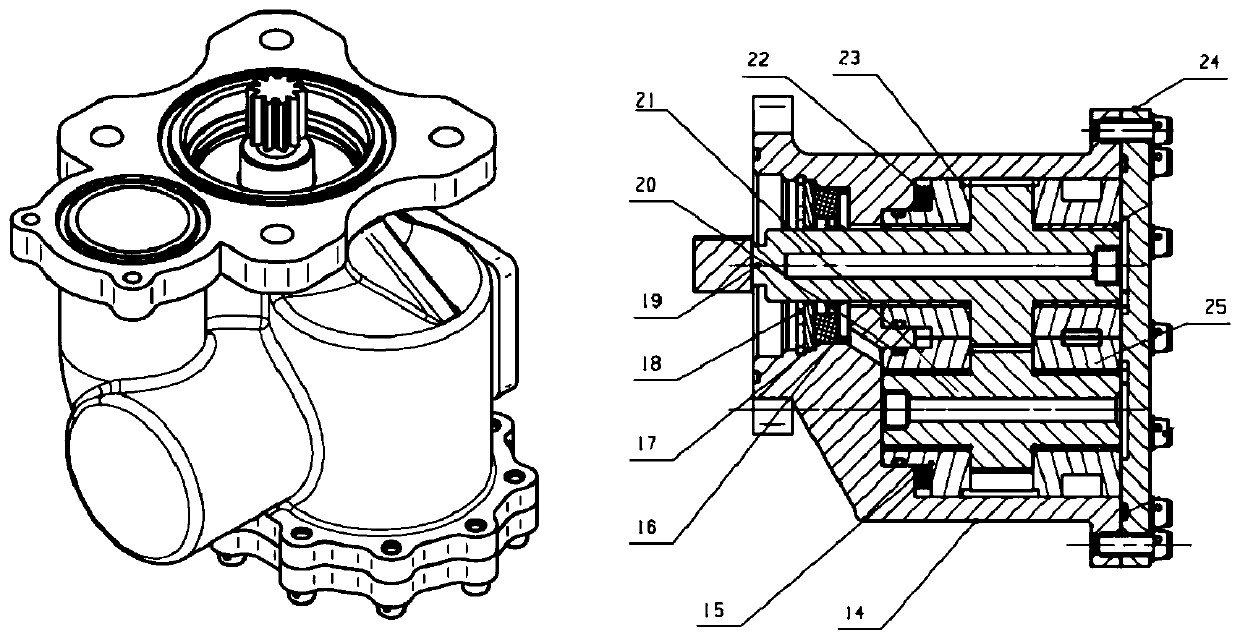

[0028] The present invention designs a combined electric pump in which the centrifugal pump and the gear pump are arranged at both ends of the driving motor. The two pumps work on the same axis and at the same speed as the motor. The centrifugal pump provides cooling fuel at a certain pressure for the motor, and at the same time ensures the inlet pressure demand of the gear pump; The gear pump adopts the gear pump with end surface compensation structure. By introducing the high-pressure oil at the outlet of the pump into the rear end surface of the gear floating bearing assembly, by reasonably determining the area of the contact surface and pressure bearing surface, the high pressure oil can form a counter pressure on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com