Shearing-bending parallel staged hierarchical energy-dissipation damper

A yield type damper and damper technology, which is applied in the direction of building types, buildings, building components, etc., can solve the problems that the damper’s yield bearing capacity is limited, cannot play the role of energy consumption, and dissipate earthquake energy, etc., to achieve energy consumption Remarkable effect, strong deformation ability, and the effect of reducing vibration response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

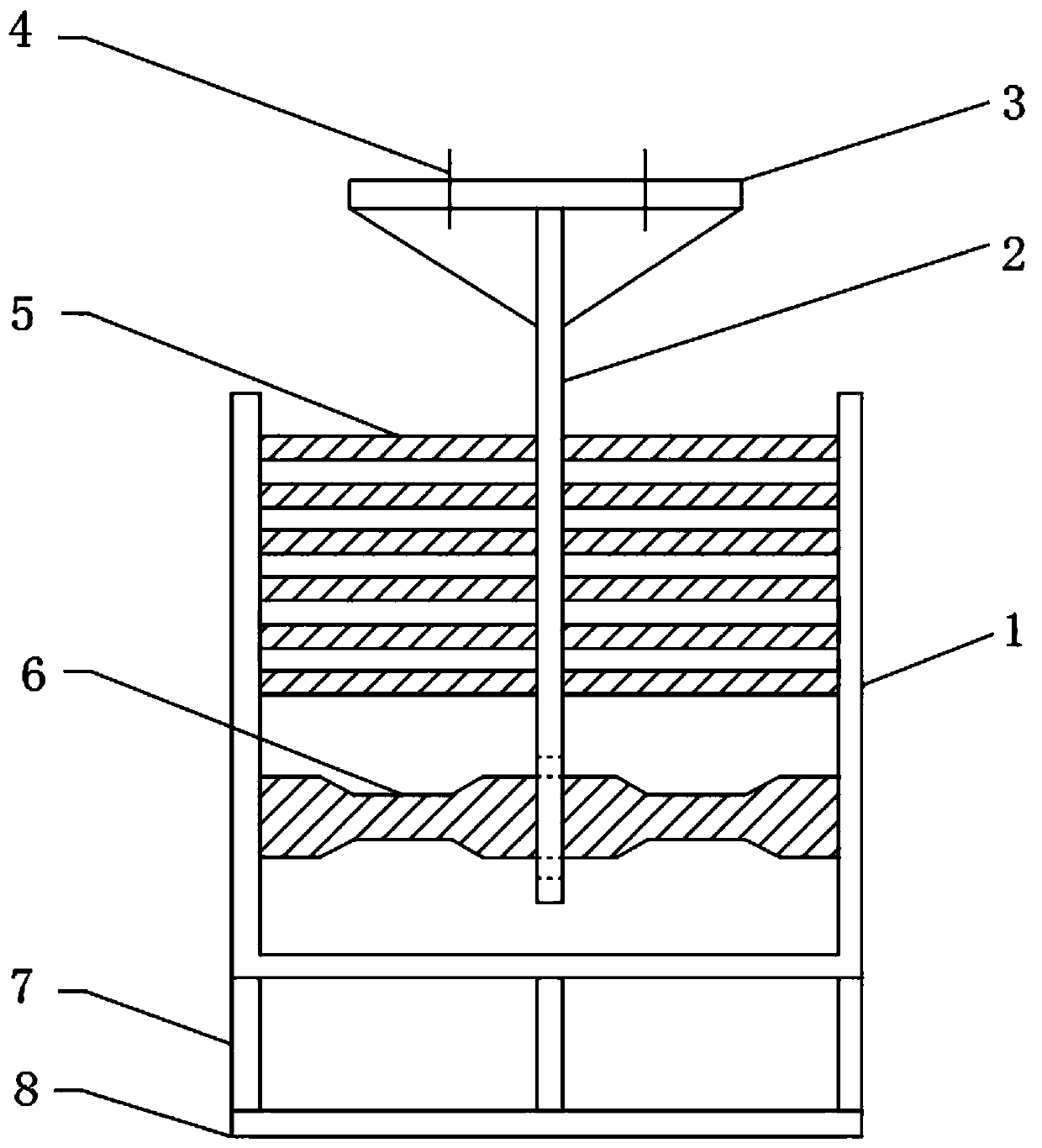

[0044] The embodiment of the present invention discloses a shear-bending parallel type graded energy-dissipating damper, including: a groove-shaped steel plate base 1, a steel plate 2, a bending yield type damper 5, and a shear yield type damper 6;

[0045] One end of the grooved steel plate base 1 is open;

[0046] The steel plate 2 extends from the opening end of the grooved steel plate base 1 to the inside of the grooved steel plate base 1; the bottom of the steel plate 2 is provided with a strip-shaped hole 21;

[0047] The shear yield type damper 6 passes through the elongated hole 21, and its two ends are connected with the inner side wall of the grooved steel plate base 1;

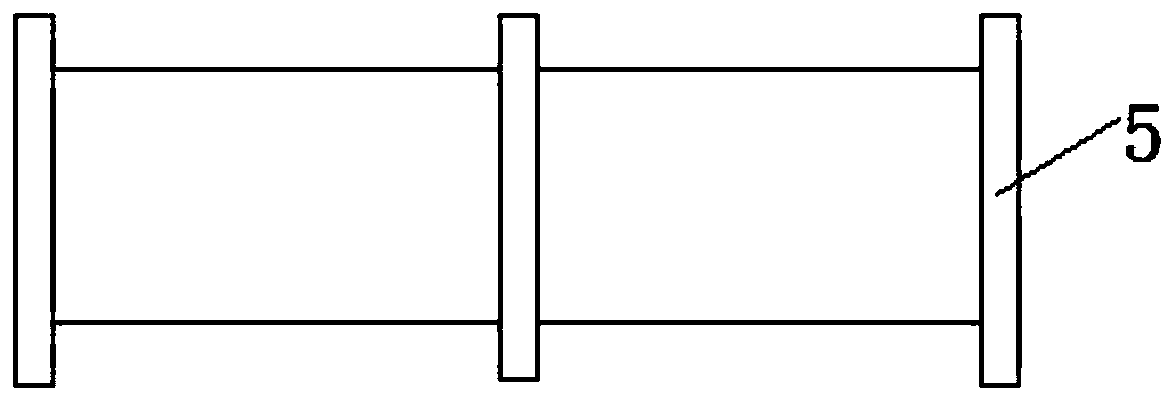

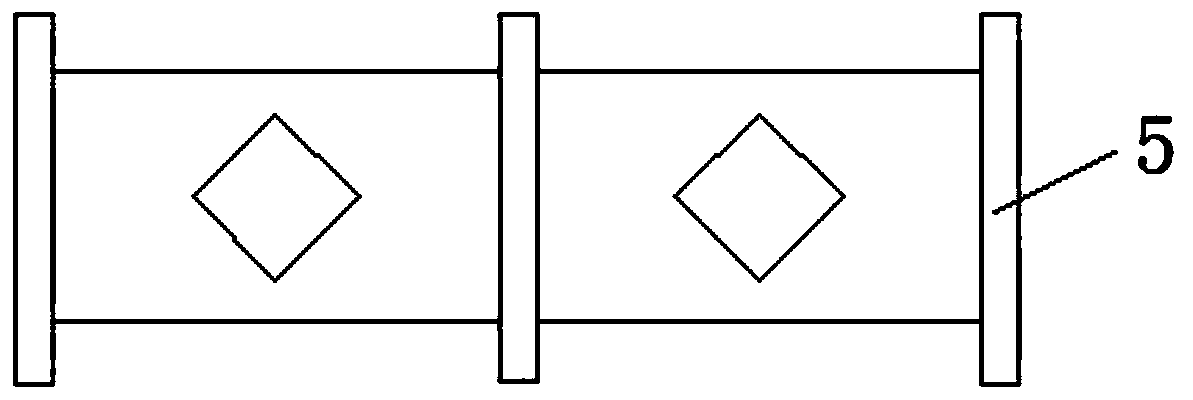

[0048] There are multiple bending yield dampers 5 arranged side by side on both sides of the steel plate 2, the other end of the bending yield damper 5 is connected to the inner side wall of the groove base 1, and is located at the edge of the shear yield damper 6. above.

[0049]In order to furth...

Embodiment 2

[0058] The bending-shearing parallel stepped energy dissipation damper is obliquely arranged inside the frame structure 14, wherein the two ends of the bending-shearing parallel stepped energy dissipation damper are respectively connected to the frame structure 14 through the rigid support 12 and the hinged support 13. two opposite corners.

[0059] In order to further optimize the above technical solution, a first rigid support 12 is connected between the first flange 3 and the upper hinged support 13 , and a second rigid support 16 is connected between the bottom plate 8 and the lower hinged support 13 . The connecting portion between the first rigid support 12 and the first flange 3 is provided with a second flange 17, the second flange 17 is the same size as the first flange 3, and is connected by high-strength bolts 4; the second rigid A third flange 18 is provided at the joint between the support 16 and the bottom plate 8, and the third flange 18 is the same size as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com