Beam section transportation method for bridge girder cantilever assembly

A transportation method and beam segment technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complicated construction procedures, high requirements for working environment conditions, and high construction costs, so as to reduce additional engineering volume and avoid additional engineering The effect of cost, construction and operation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

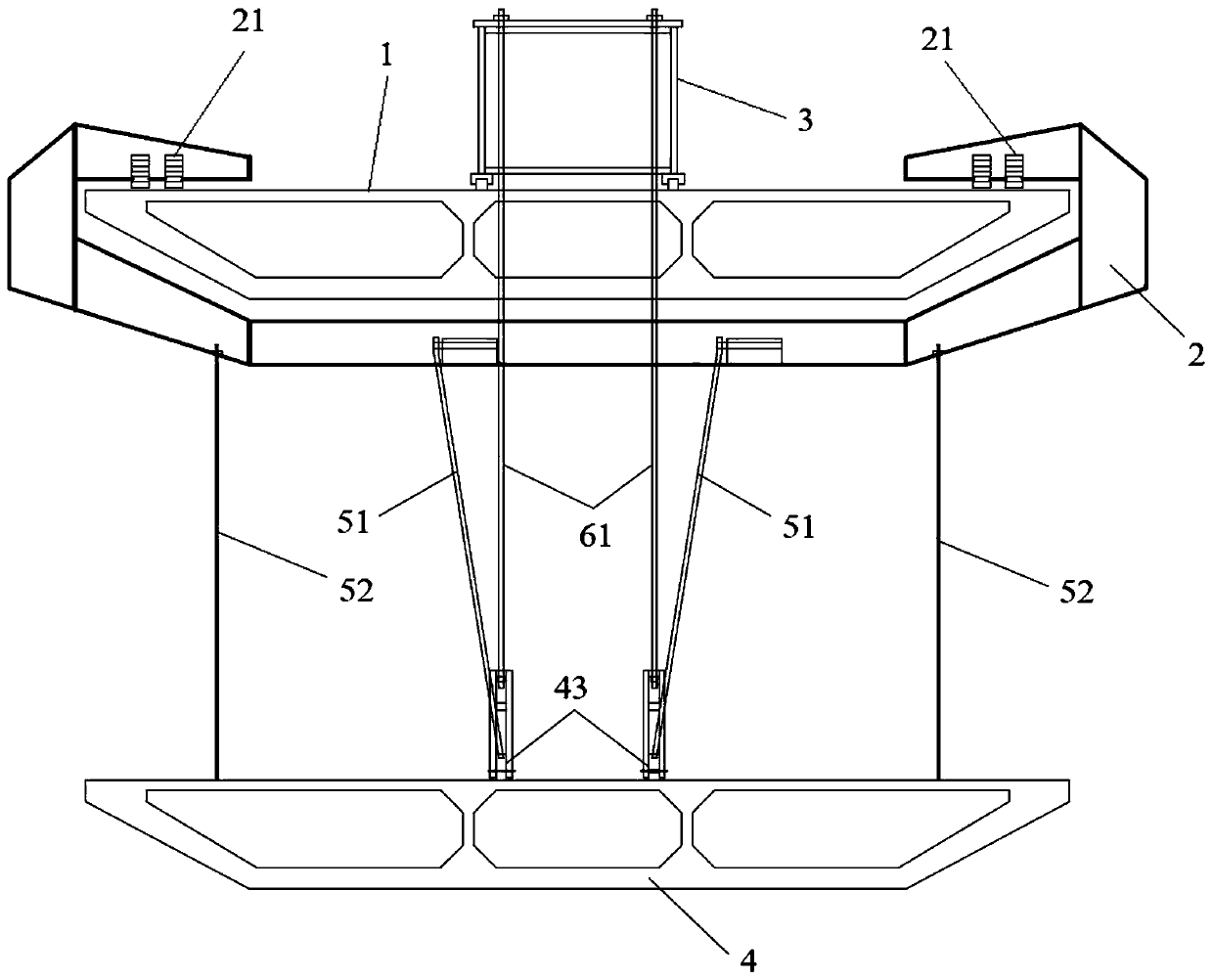

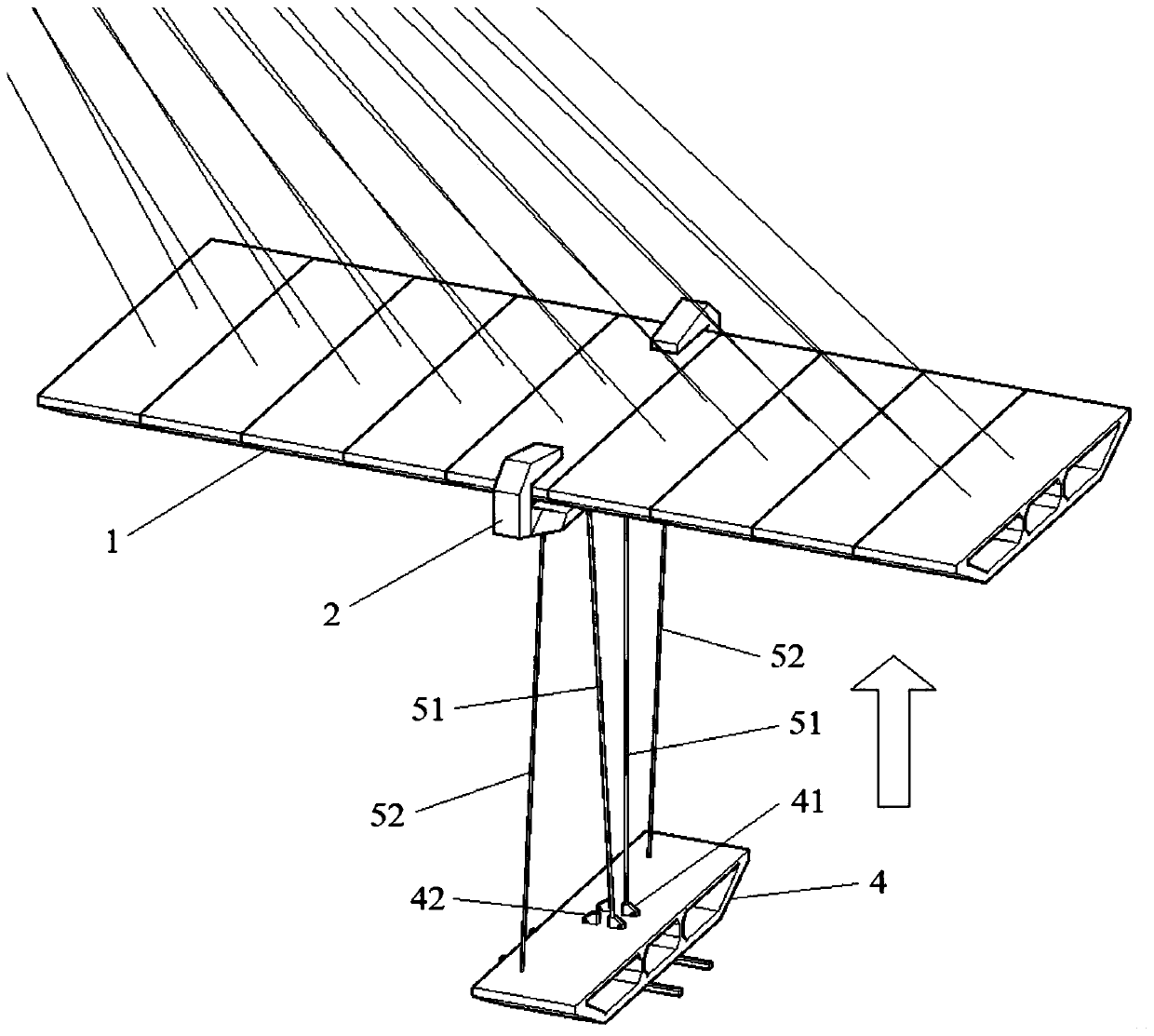

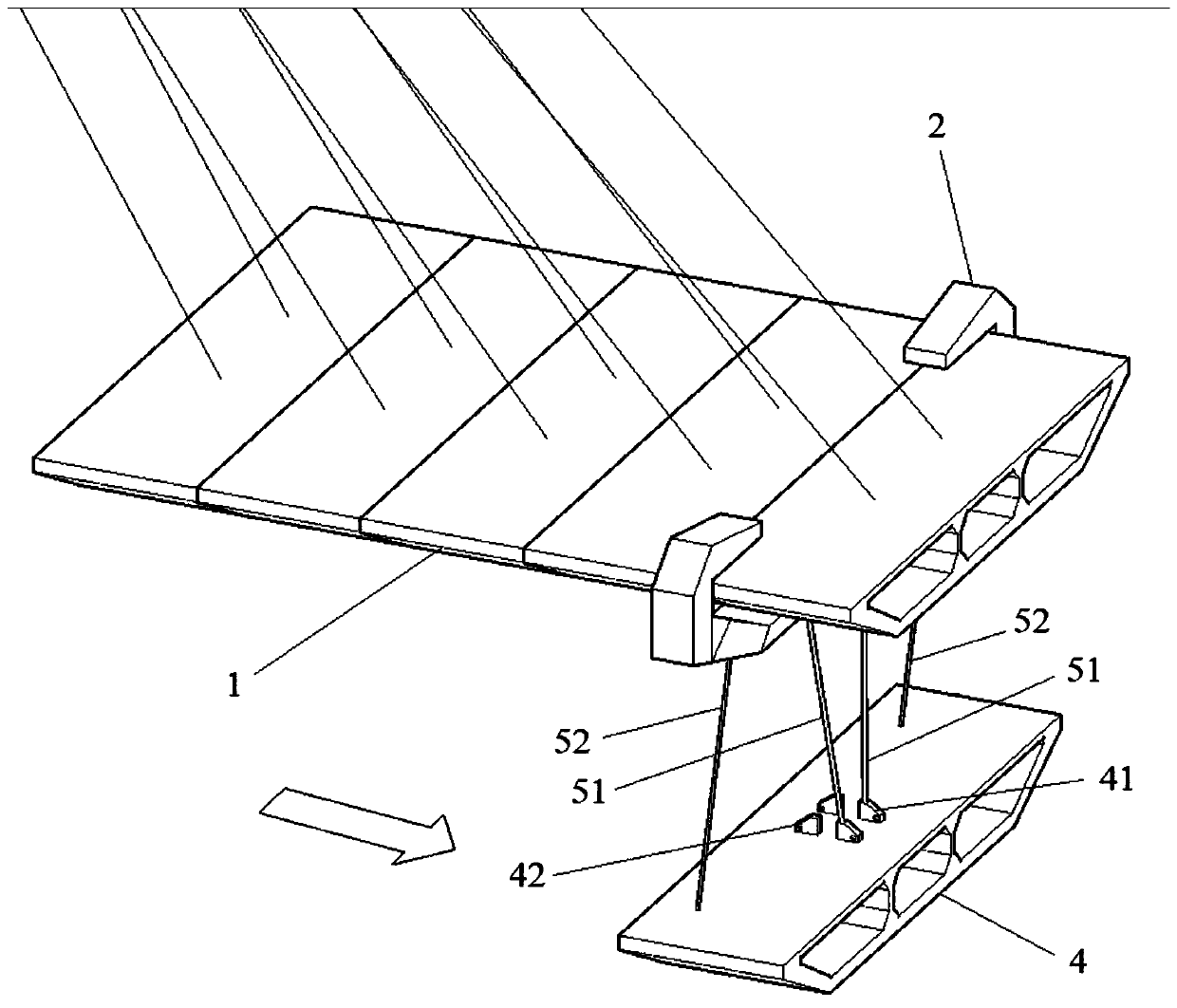

[0046] A method for transporting bridge girder cantilever-assembled girder sections according to the present invention includes a transport device, and the transport device includes a beam transport vehicle 2 connected below the installed girder section 1 and a beam transport vehicle 2 connected to the installed girder section 1 The beam erecting machine 3 above, the beam transport vehicle 2 includes a walking part 21 and a lifting part 1, and the beam erecting machine 3 includes a walking part 2 31 and a lifting part 2;

[0047] Contains the following steps:

[0048] Step 1. Install the beam erecting machine 3 on the installed beam section 1, and hoist the beam transport vehicle 2 to a predetermined position through the beam erecting machine 3;

[0049] Step 2, transporting the beam section 4 to be installed to the lifting point of the beam truck 2;

[0050] Step 3: Connect the lifting part 1 to the beam section 4 to be installed, and the beam transport vehicle 2 transports ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com