A strain of Sphingosine polyphaga and its application

A technology of sphingosine bacteria and microbial strains, applied in the field of microorganisms, can solve the problem of not effectively degrading cellulose and the like, achieve high economic and social benefits, increase the degradation rate, and improve the effects of soil microecology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

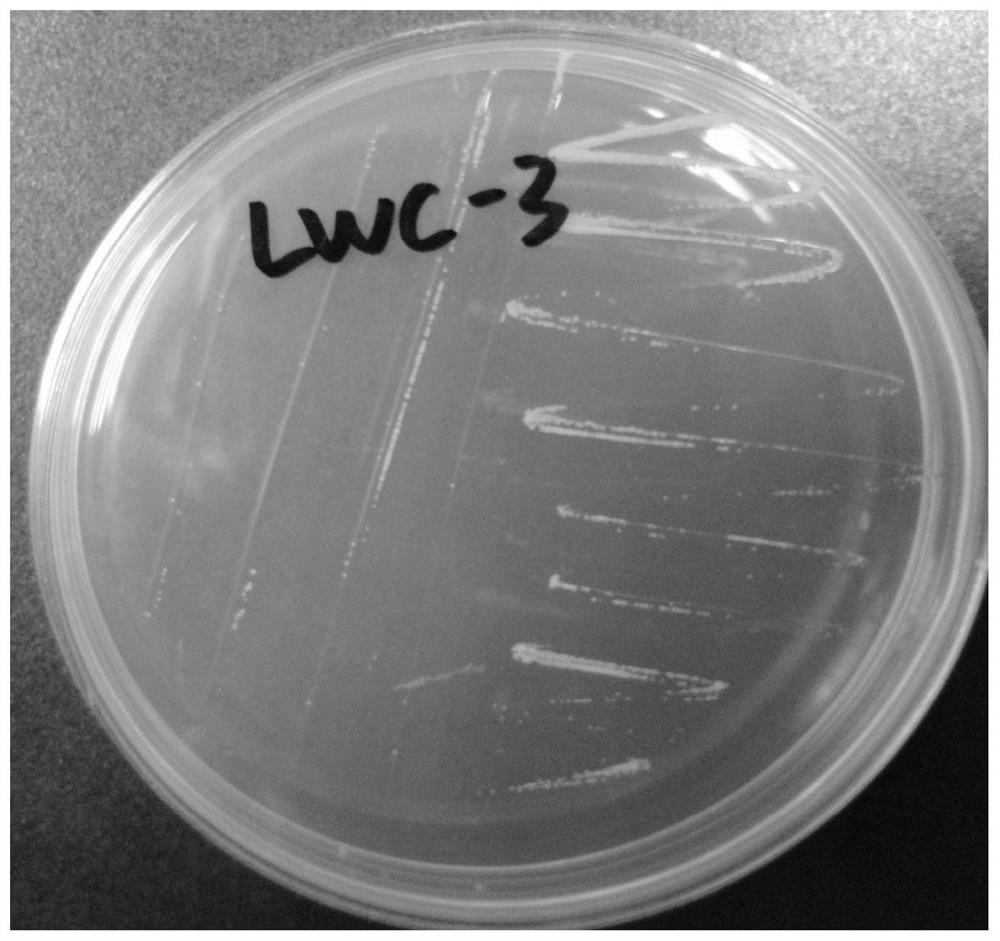

Image

Examples

Embodiment 1

[0036] Example 1. Isolation and identification of cellulolytic bacteria

[0037] 1. Isolation of Cellulolytic Bacteria

[0038] The Sphingobacterium multivorum of the embodiment of the present invention was isolated from the soil of Xuancheng, Anhui. The method for the separation of Sphingobacterium multivorum adopts the conventional method in the art for screening new strains, the soil circulation separation combined with the dilution plate purification method. Specific steps are as follows:

[0039]200g of soil collected from Xuancheng, Anhui and 10g of straw were weighed and put into the circulation enrichment device. 1500mL of inorganic salt liquid culture medium after sterilization at 121°C for 15min was pumped into the fluidized bed with a peristaltic pump, the speed of the peristaltic pump was 170rpm, and the air pump exhaust volume was 2L·min -1 , replenish the inorganic salt medium solution into the fluidized bed at regular intervals, and periodically add the circu...

Embodiment 2

[0052] Embodiment 2, Sphingosine polyphaga produces cellulase, hemicellulase activity

[0053] 1. Preparation of crude enzyme solution

[0054] Sphingomyelinum polyphaga was inoculated into straw cellulase-producing medium for cultivation. After culturing for 6 days, 7 mL of the liquid was taken out into a centrifuge tube, centrifuged at 4°C and 5000 rpm for 10 min, and the supernatant was taken as the crude enzyme liquid.

[0055] 2. Determination of cellulase activity

[0056] Take 4 clean and dried test tubes, numbered 1-4, add 1.5 mL of 0.5% sodium carboxymethyl cellulose solution to each test tube, add 2 mL of DNS solution to No. 1 test tube, and put the 4 test tubes into Preheat in a constant temperature water bath at 50 °C for 10 min; add 0.5 mL of the above crude enzyme solution to each test tube, keep the constant temperature water bath at 50 °C, and the reaction time is 30 min. Immediately after the reaction was terminated, 2 mL of DNS solution was added to the ot...

Embodiment 3

[0059] Example 3. Manganese peroxidase, laccase and lignin catalase activities of Sphingosine polyphaga

[0060] 1. Preparation of crude enzyme solution

[0061] Take 5 g of 1-2 cm straw segments, add 50 mL of straw ligninase-producing medium to them, and sterilize at 121° C. for 15 min. The Sphingosine polyphaga was inserted into the lignin enzyme production medium, placed in a 30°C incubator for cultivation, and water was regularly replenished to maintain the initial humidity. On the 6th day, take 1g of straw and add 20ml of 0.2mol·L -1 Acetic acid buffer solution (pH=5.0) was placed on a constant temperature oscillator at 30° C. for leaching for 2 hours, and the obtained leaching solution was the crude enzyme solution.

[0062] 2. Determination of manganese peroxidase, laccase and lignin catalase activities

[0063] To 3.4mL 0.11mol L -1 Lactic acid-sodium lactate buffer solution (pH=4.5) was added with 0.1mL40mmol·L -1 MnSO 4 The solution was preheated in a constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com