High weather resistance black polycarbonate material selectively transparent to visible light and preparation method thereof

A polycarbonate and visible light technology, applied in the field of polymer materials, can solve the problems of inability to realize the light transmission effect of high-gloss black materials, visible light transmittance and loss of control of light transmission color, etc., to achieve strong applicability, good weather resistance, Good uniformity of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

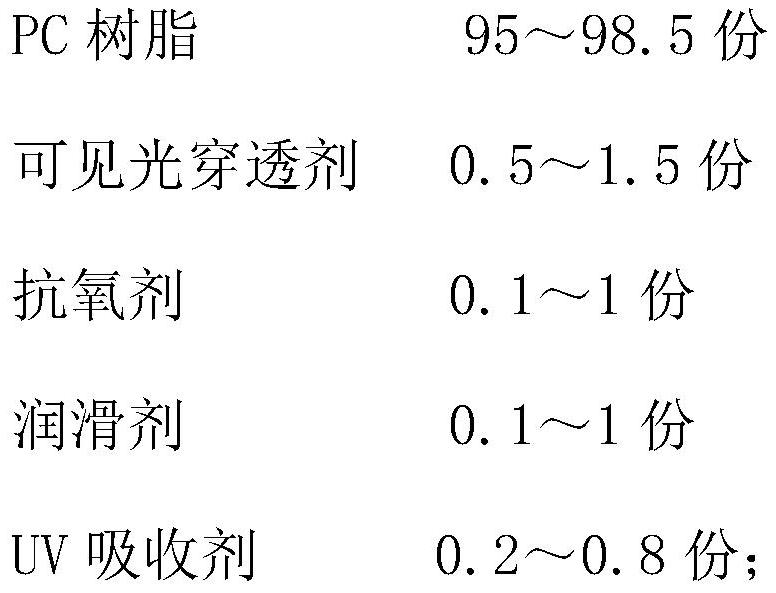

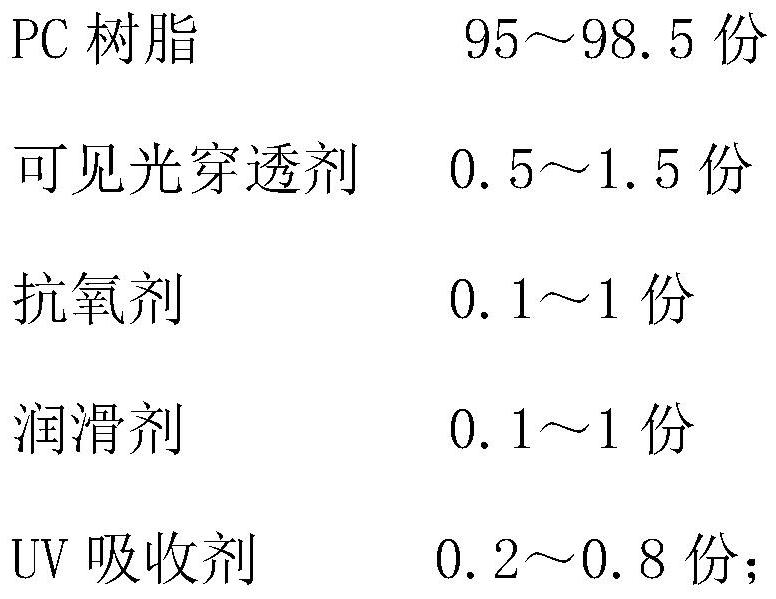

[0038] A method for preparing a highly weather-resistant black polycarbonate material selectively transparent to visible light comprises the following steps:

[0039]A, take by weight PC resin, visible light penetrating agent, antioxidant, lubricant and UV absorber for subsequent use;

[0040] B. Mix the components weighed in the step A at a high speed to obtain the mixture;

[0041] C. After the mixture obtained in step B is subjected to twin-screw melt extrusion, water cooling and air-drying and pelletizing, a highly weather-resistant black polycarbonate material that selectively transmits visible light is obtained.

[0042] Through the use of azo-type and anthraquinone-type weakly acidic visible light penetrants, polycarbonate materials can control the light transmission color and light transmittance in the visible light band. In addition, adding antioxidants and UV absorbers to the system can effectively To improve the weather resistance of polycarbonate materials, the pr...

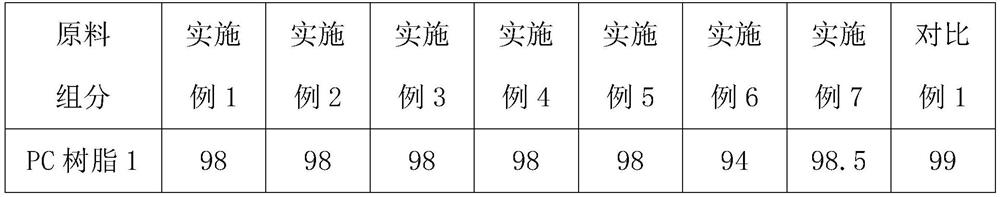

Embodiment 1~7 and comparative example 1

[0066] A highly weather-resistant black polycarbonate material selectively transparent to visible light, prepared according to the following steps:

[0067] (1) Calculated according to parts by weight, each raw material is taken by weighing the raw material component content in Table 1 for subsequent use;

[0068] (2) Add each component weighed in the step (1) into a high-speed mixer and stir and mix evenly, the rotating speed of mixing and stirring is 350r / min, and the mixing time is 15min to obtain a mixture;

[0069] (3) Put the mixture obtained in step (2) into a twin-screw extruder for twin-screw melt extrusion. The extrusion temperature is 260°C, the screw speed is 300rpm, and the extrusion pressure is 2MPa. After water cooling and air-drying, pelletize Finally, high-weather-resistant black polycarbonate material pellets that selectively transmit visible light were obtained, and then a 150*100*3mm sample was prepared after injection molding for various performance tests....

Embodiment 8

[0080] A highly weather-resistant black polycarbonate material selectively transparent to visible light, prepared according to the following steps:

[0081] (1) Calculated in parts by weight, take 98 parts of PC resin 2, 1 part of visible light penetrating agent 5, 0.3 part of antioxidant, 0.2 part of lubricant and 0.5 part of UV absorber for subsequent use;

[0082] (2) Add each component weighed in the step (1) into a high-speed mixer and stir and mix evenly, the rotating speed of mixing and stirring is 350r / min, and the mixing time is 15min to obtain a mixture;

[0083] (3) Put the mixture obtained in step (2) into a twin-screw extruder for twin-screw melt extrusion. The extrusion temperature is 260°C, the screw speed is 300rpm, and the extrusion pressure is 2MPa. After water cooling and air-drying, pelletize Finally, high-weather-resistant black polycarbonate material pellets that selectively transmit visible light were obtained, and then a 150*100*3mm sample was prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com