Drive unit

A drive unit and component technology, applied in the direction of power devices, electric power devices, jet propulsion devices, etc., can solve the problems of not being able to block the vibration of the motor, and cannot ensure the support strength and rigidity, so as to improve diversity, suppress vibration and vibration sound, the effect of improving ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

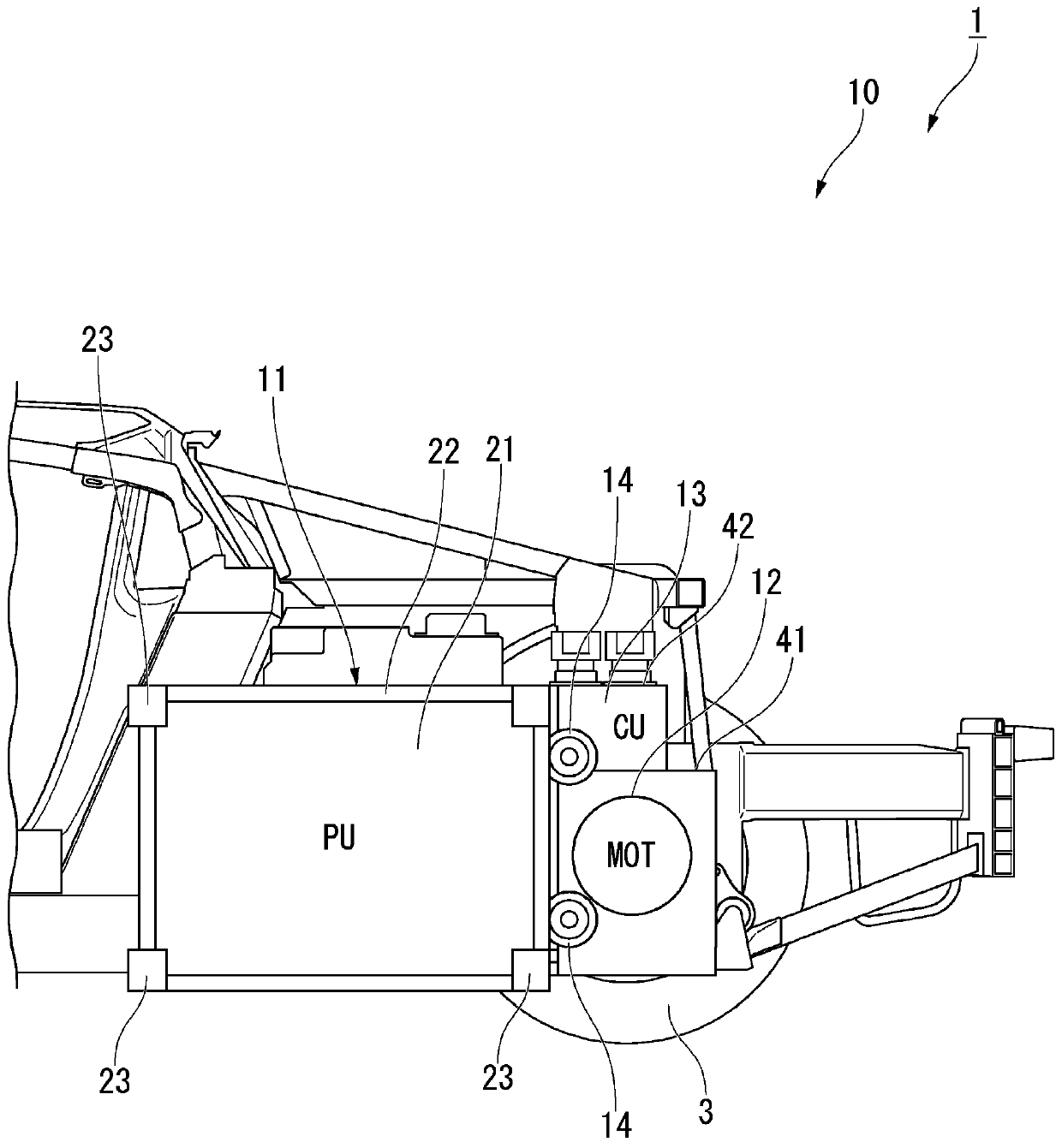

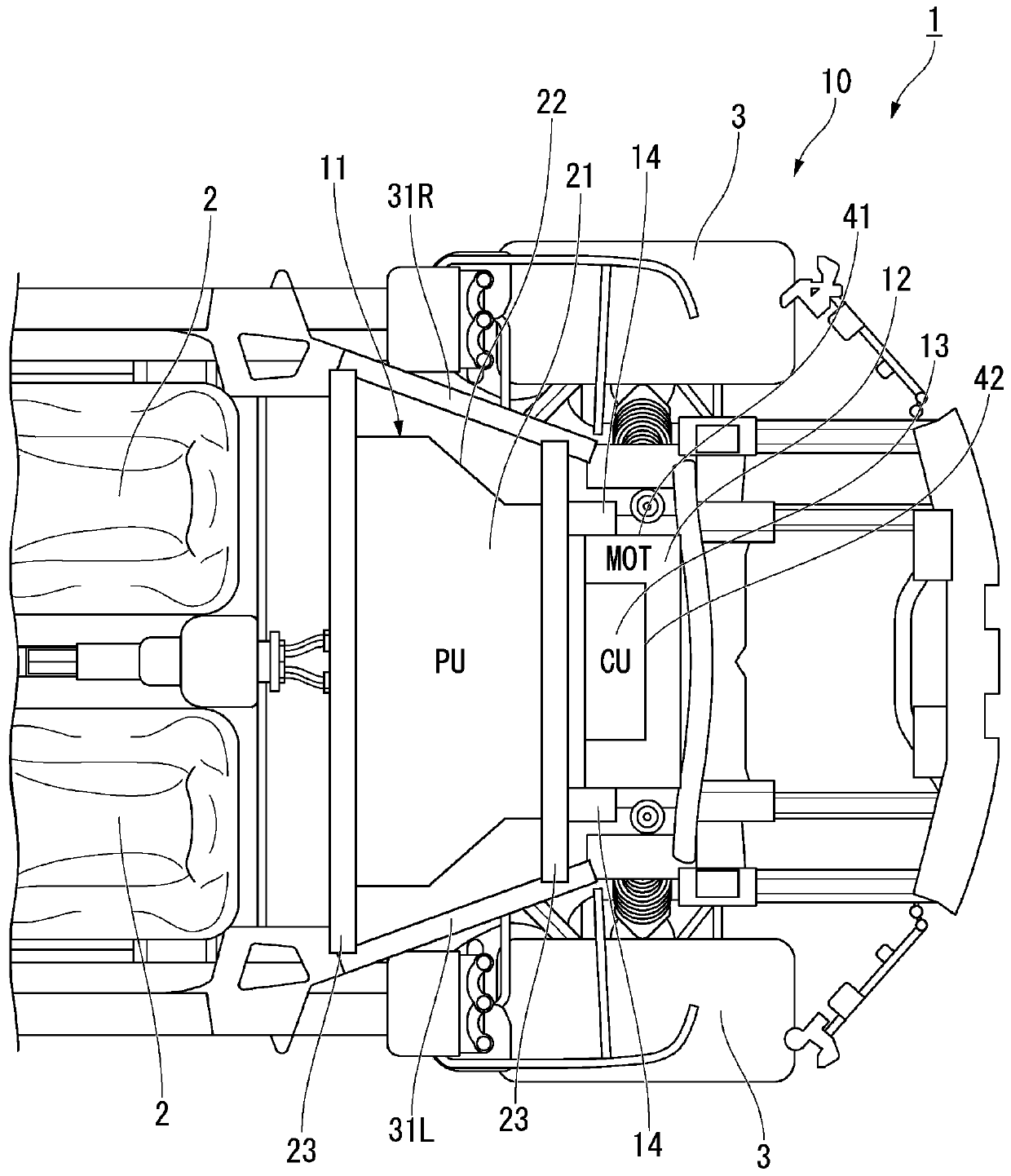

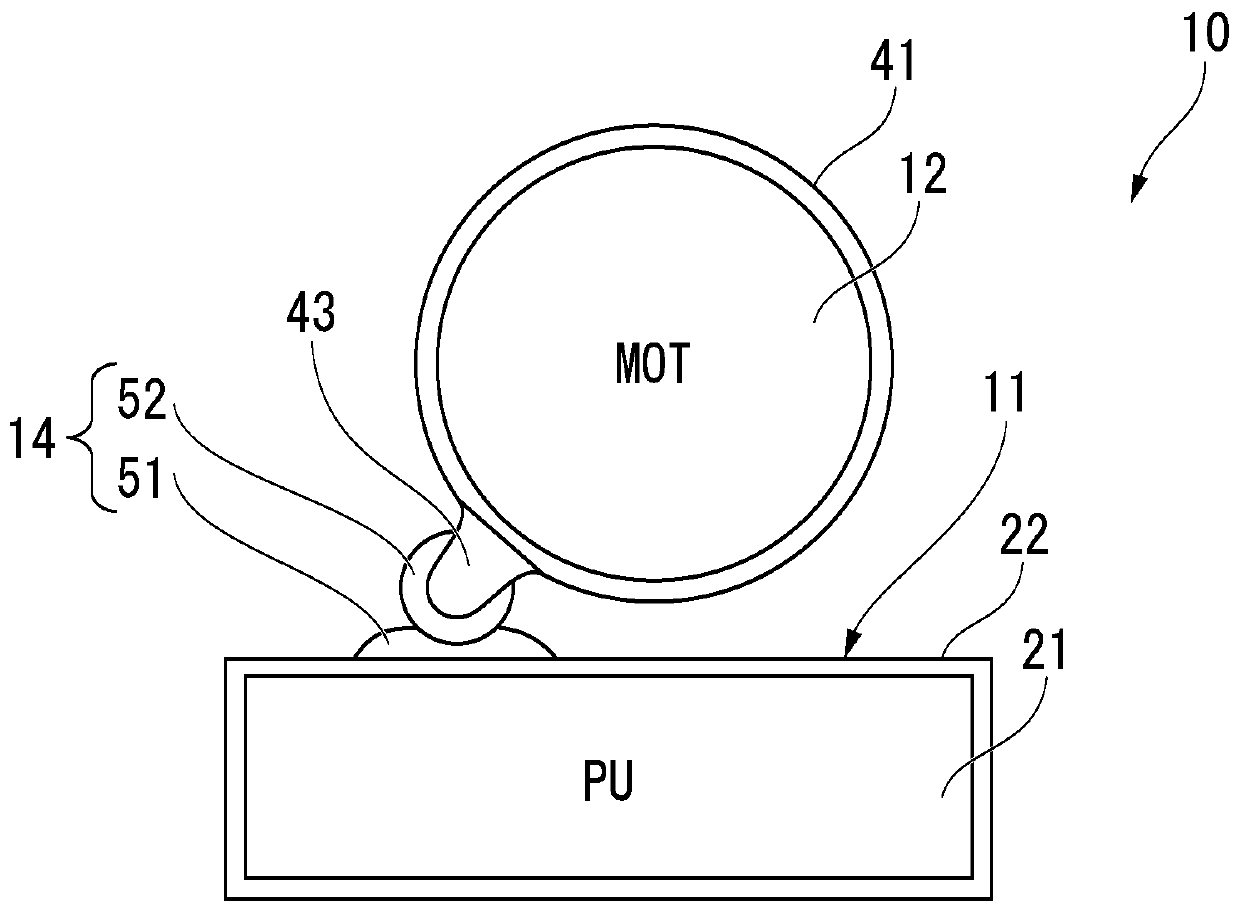

[0031] Hereinafter, a drive unit according to an embodiment of the present invention will be described with reference to the drawings.

[0032] The drive unit according to the embodiment of the present invention is mounted on, for example, the vehicle 1 . The vehicle 1 is, for example, an electric vehicle such as an electric vehicle, a hybrid vehicle, or a fuel cell vehicle. Electric vehicles are powered by batteries. A hybrid vehicle is driven by a battery and an internal combustion engine as power sources. A fuel cell vehicle is driven by a fuel cell as a driving source.

[0033] figure 1 It is a figure which schematically shows the structure of a part of the vehicle 1 equipped with the drive unit 10 which concerns on embodiment of this invention, and is a figure seen from the left side of the left-right direction of a vehicle. figure 2 It is a figure which schematically shows the structure of a part of the vehicle 1 equipped with the drive unit 10 which concerns on emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com