Corrugating machine with humidifying and heating function

A corrugating machine and functional technology, applied in the direction of mechanical processing/deformation, can solve the problems of fiber brittleness, affecting the quality of cost corrugated cardboard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments:

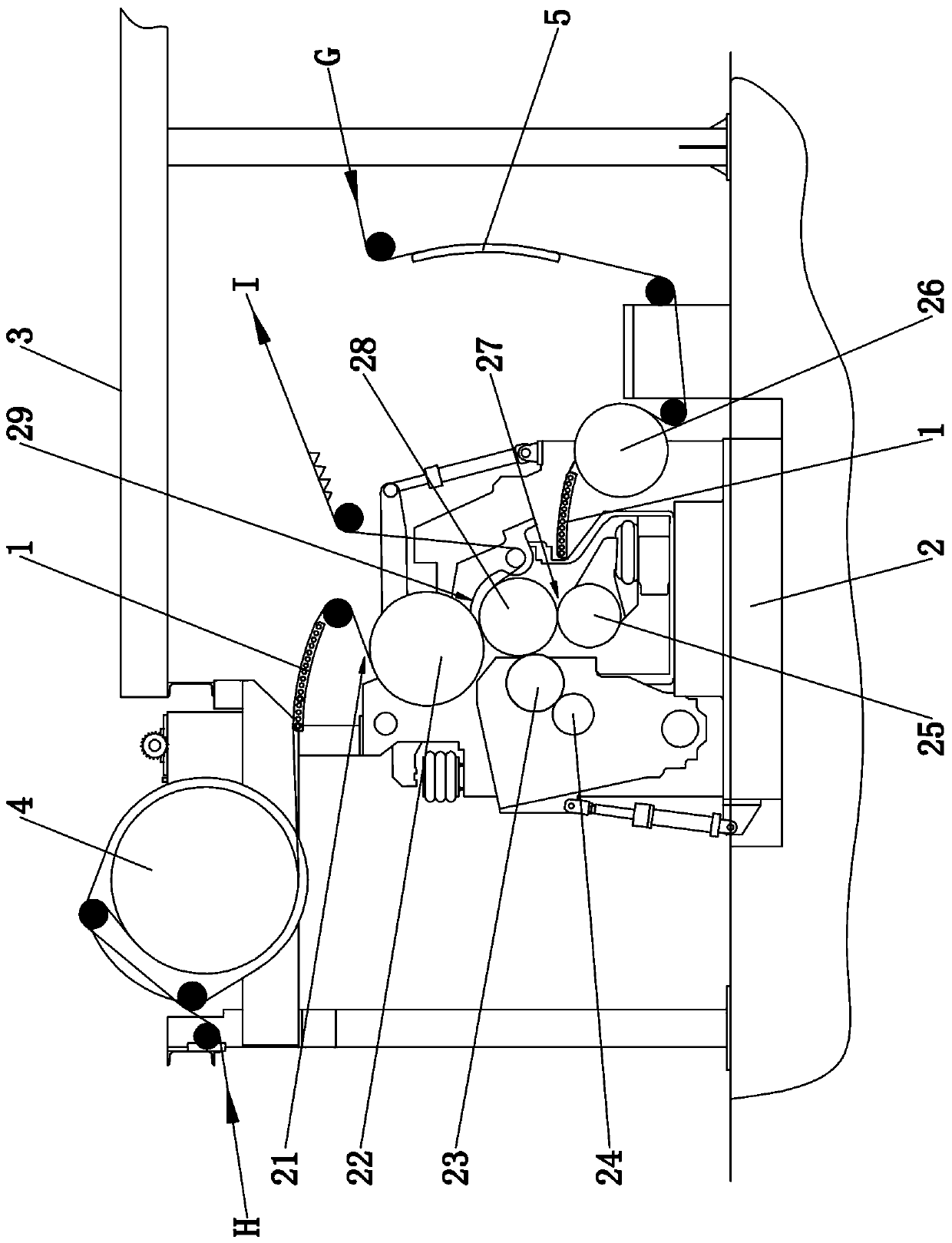

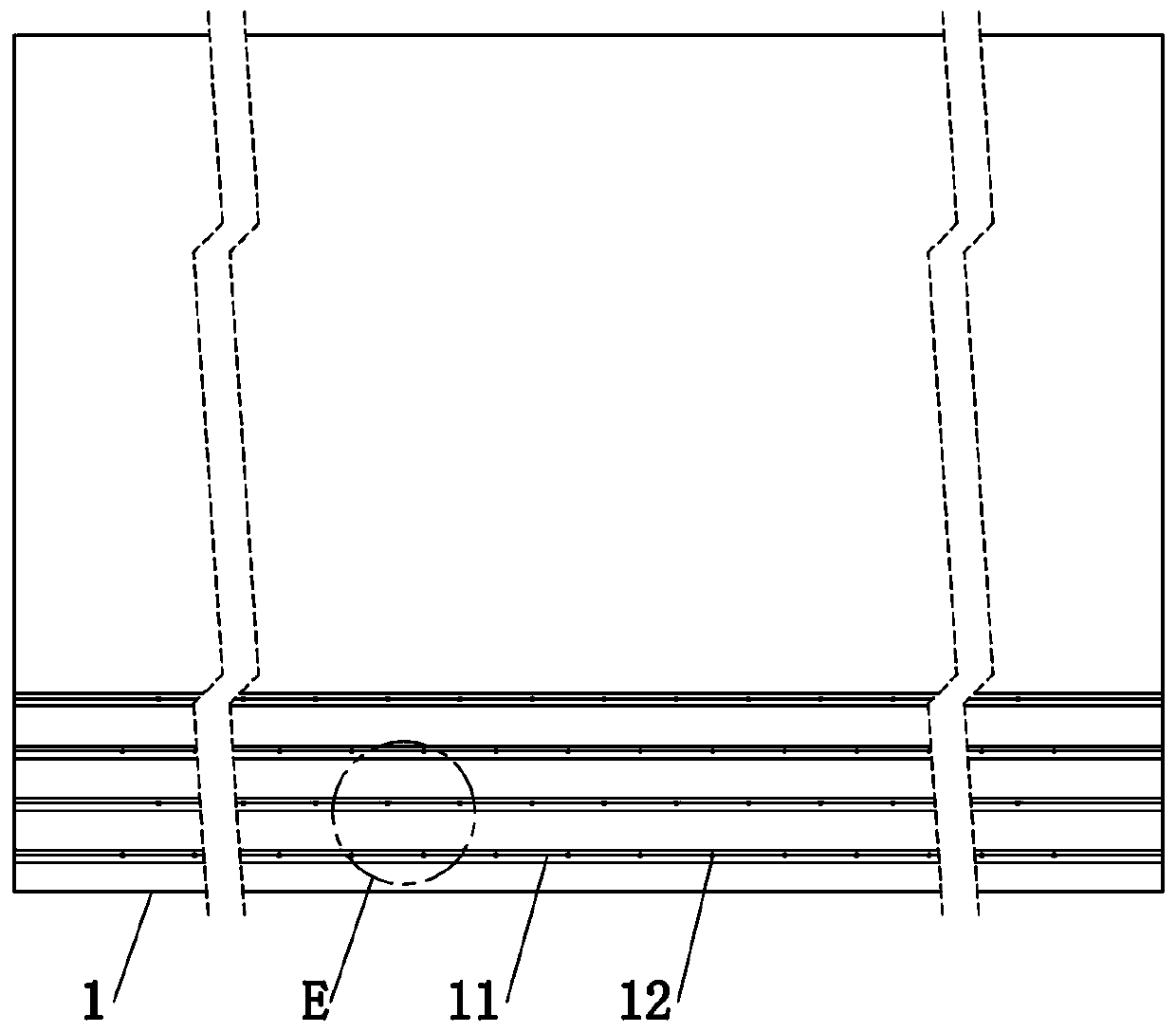

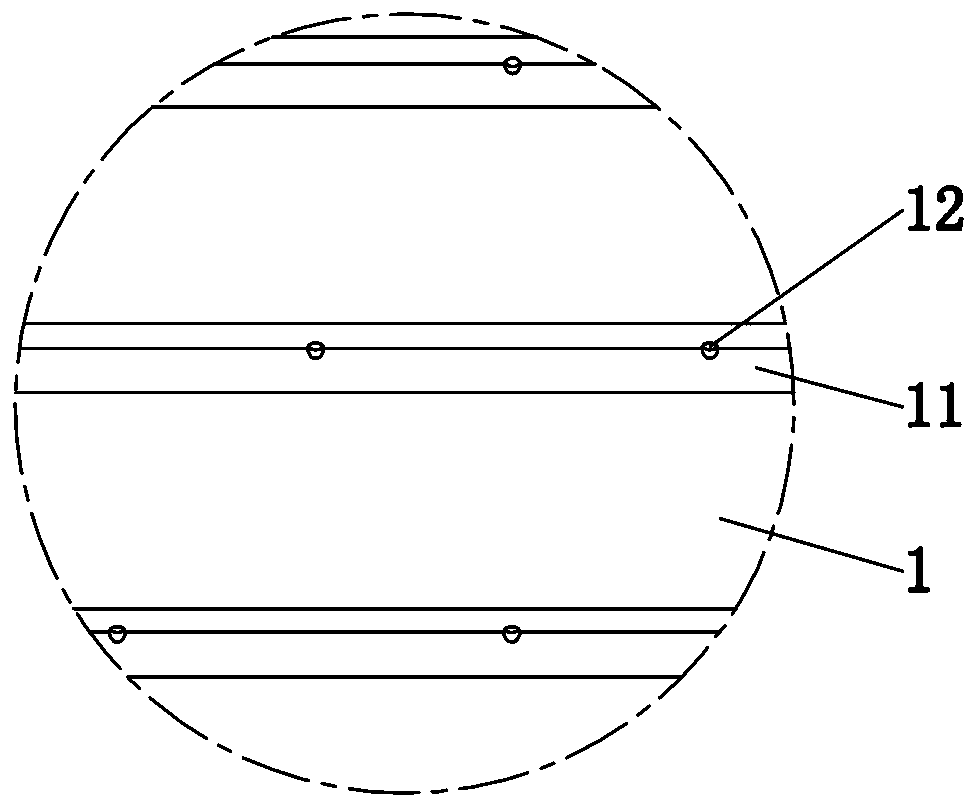

[0025] See Figure 1 to Figure 6 As shown, a corrugating machine 3 with humidification and heating function includes a corrugated cardboard forming assembly 2. The corrugated cardboard forming assembly 2 is provided with a facial paper input port 21, a core paper input port 27, and a cardboard output port 29. A steam heating plate 1 is provided outside the port 21 and the core paper input port 27, and a steam channel 13 is provided in the steam heating plate 1. The feature is that the surface of the steam heating plate 1 is provided with a groove 11 along its width direction. A plurality of air injection holes 12 are provided in the groove 11, and the air injection holes 12 communicate with the steam channel 13.

[0026] The steam heating plate 1 is provided with a plurality of steam passages 13, and each steam passage 13 is directed along the width direction of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com