Roller drying machine

A technology of drum dryer and outer drum, applied in dryers, biomass drying, drying of solid materials, etc., can solve the problems of high use cost of the dryer, the materials are not dried well, and the drying is uneven, and the drying effect can be improved. , Improve drying uniformity, better drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

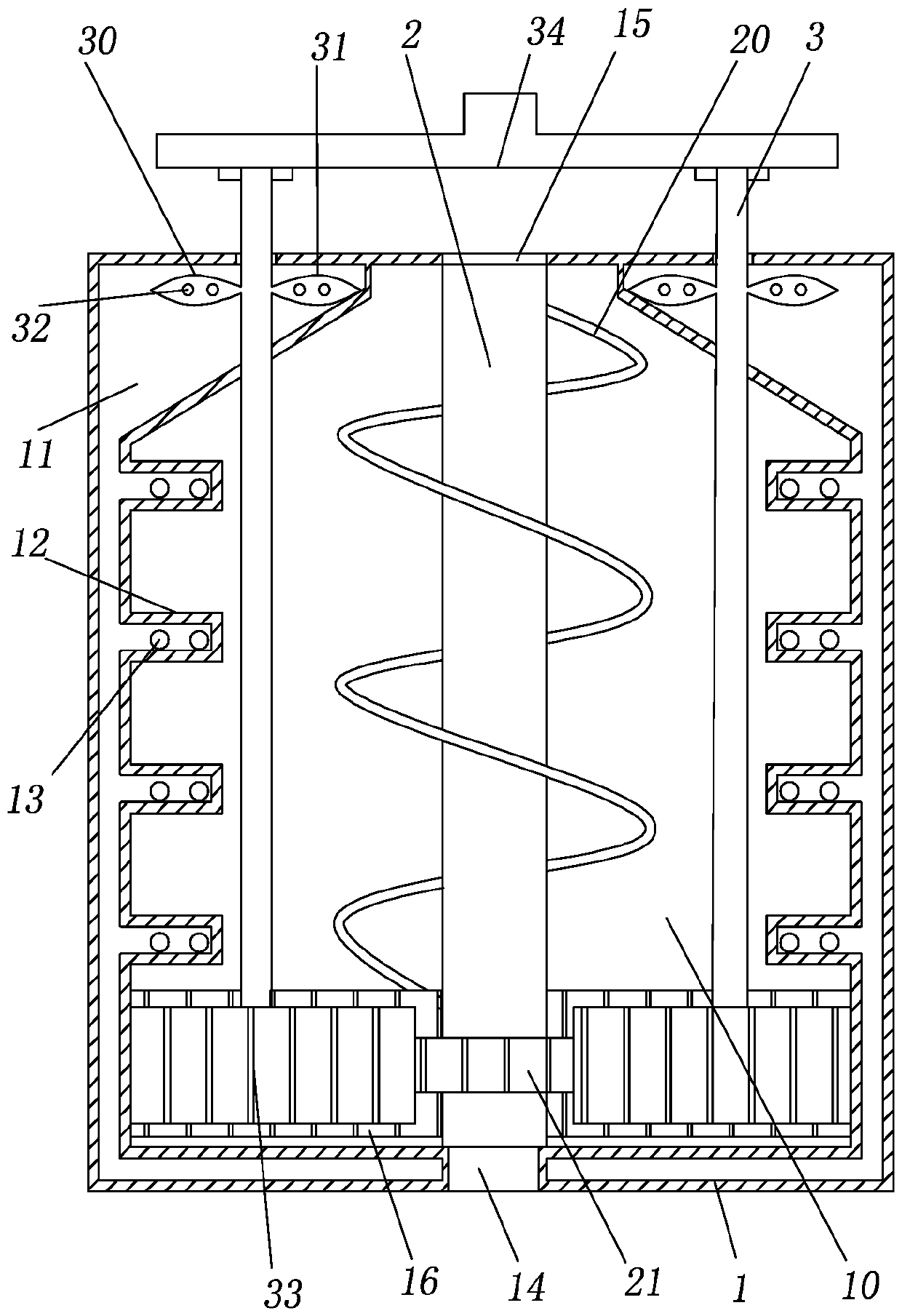

[0018] The reference signs in the drawings of the specification include: outer drum 1, drying chamber 10, interlayer 11, protrusion 12, air outlet 13, feed inlet 14, outlet 15, inner ring gear 16, inner drum 2, spiral blade 20, central gear 21, rotating cylinder 3, left blade 30, right blade 31, jet hole 32, circumferential gear 33, air intake box 34.

[0019] A tumble dryer, such as attached figure 1 As shown, it includes an outer drum 1 with a drying chamber 10, the bottom of the outer drum 1 is provided with a feed port 14, the top of the outer drum 1 is provided with a discharge port 15, and an inner drum 2 and a hollow rotating drum 3 are also included; The side wall of the drum 1 is provided with a hollow interlayer 11, and the side wall of the outer drum 1 is provided with an air outlet 13 for communicating with the interlayer 11 and the drying chamber 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com