A Pneumatic Gripper Device with Sensor Control

A pneumatic fixture and sensor technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of mass production of unfavorable sensors, low production efficiency and high cost, and achieve the effects of simple structure, improved production efficiency and low input cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

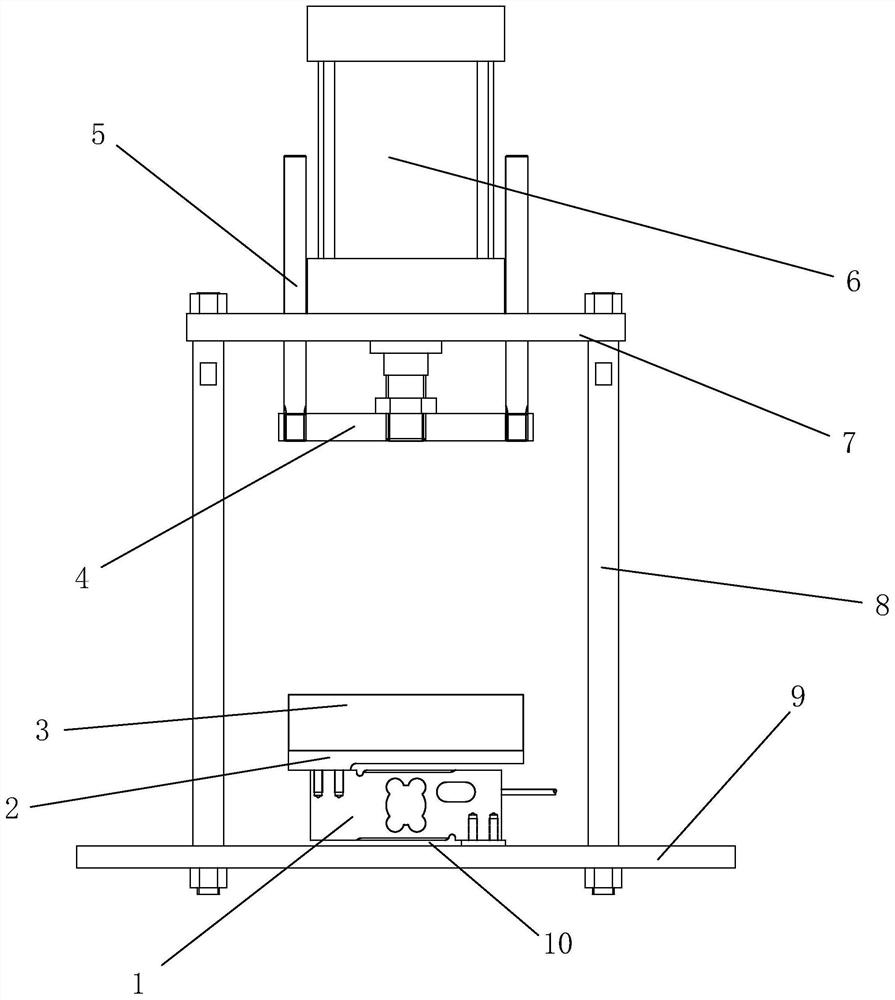

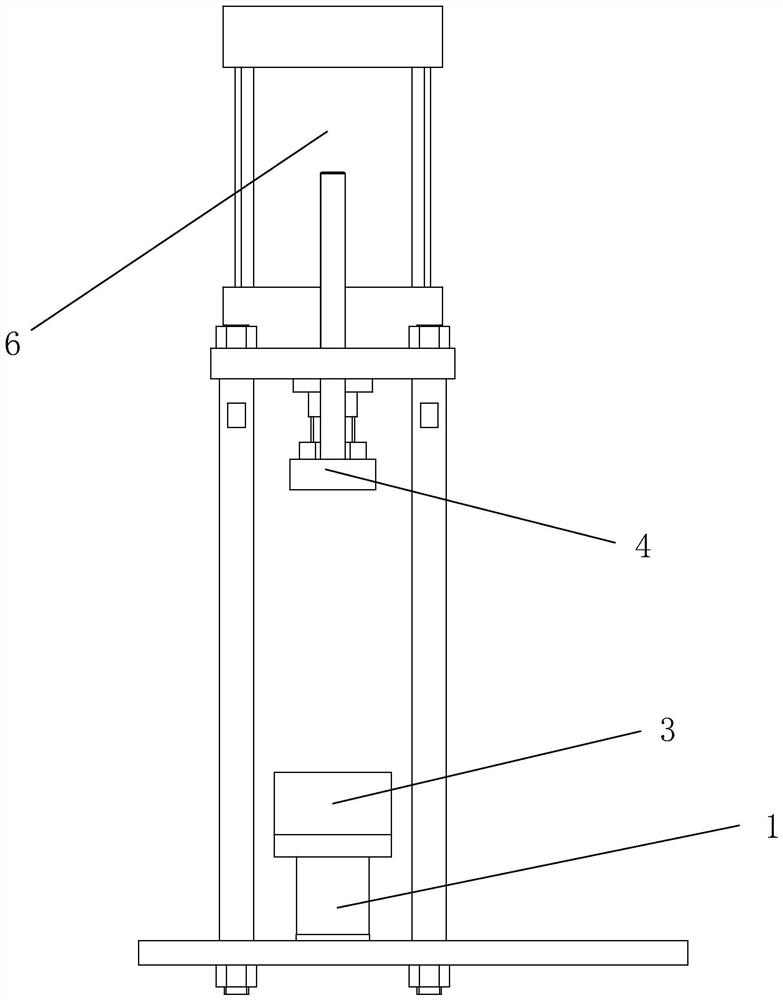

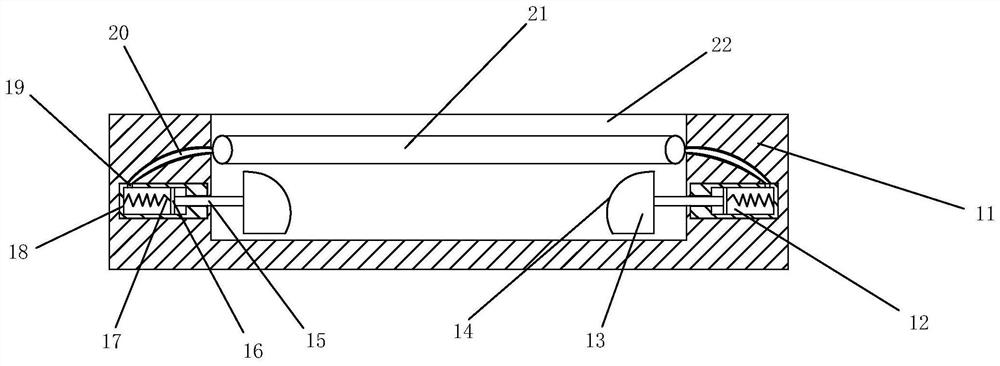

[0020]Such asfigure 1 ,2As shown, a pneumatic clamp device controlled by a sensor 1 includes a lower bottom plate 9 and a lower bottom plate 7, a lower bottom plate 9 and a upper bottom plate 7, and a cylinder 6 is attached to the upper bottom plate 7, the upper bottom plate 7 is mounted on the upper bottom plate 7, the piston of the cylinder 6 After the 16 rod passes through the upper bottom plate 7, the top plate 4 is connected, and the lower bottom plate 9 is provided with a sensor 1 for measuring the clamping force of the clamp, and the sensor 1 is called the heavy force sensor 1, which is convenient, and the output value is accurate. Sex, the sensor 1 is provided with a pressure plate 2 for placing the clamp, and the top plate 4 is pressed by the piston 16 rod on the cylinder 6, and the sensor 1 output force value is obtained to control the clamp value of the top plate 4, The clamping force is adjusted and controlled with the size of the sensor 1 output force, thereby improving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com