Physical scum isolating and pouring device for anode formwork

A slag separation and vertical mold technology, which is applied in mechanical cleaning, casting equipment, manufacturing tools, etc., can solve the problems of scum being unable to flow back and scum isolation, and achieve a balanced flow rate, enhanced stability, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

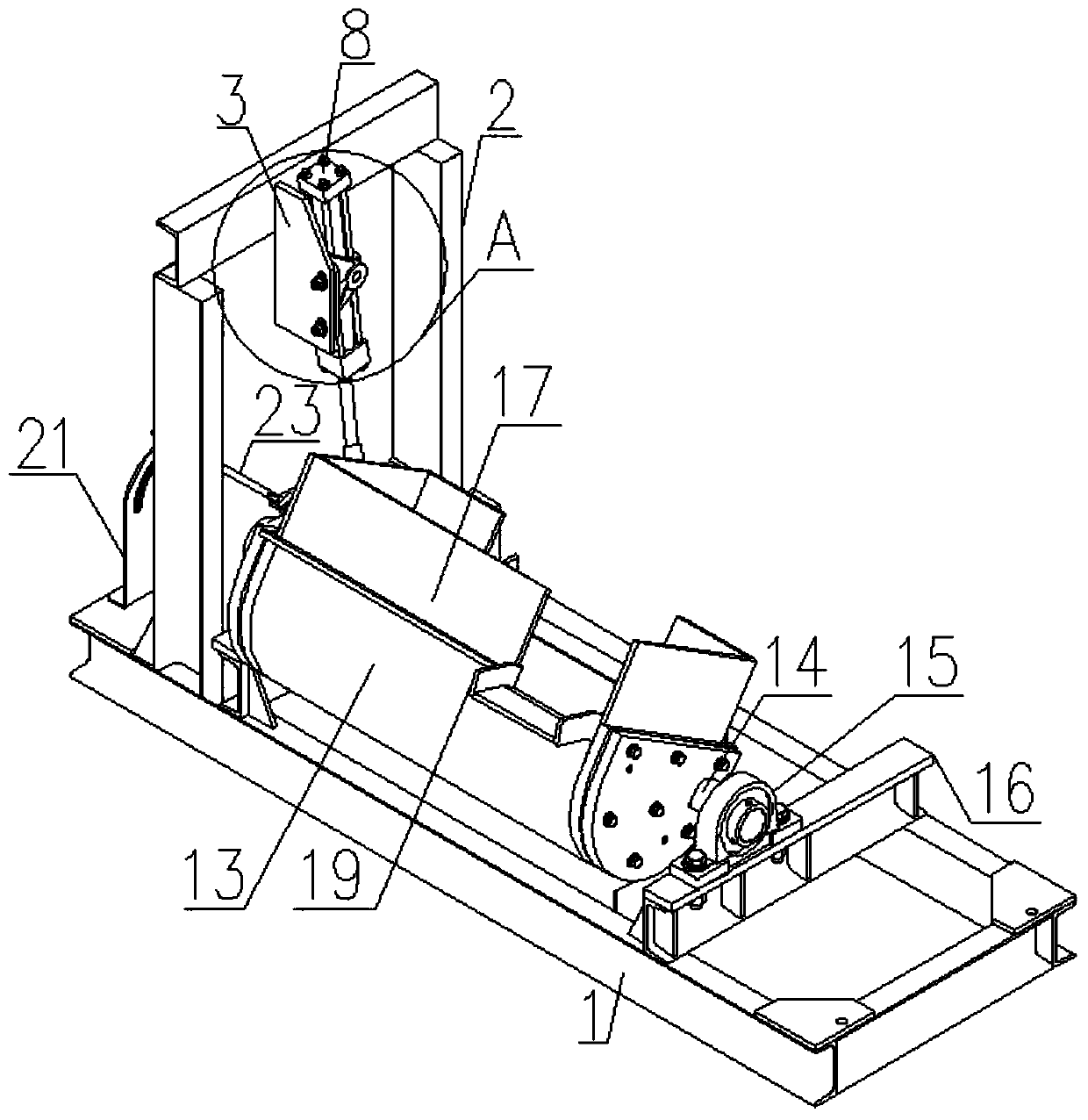

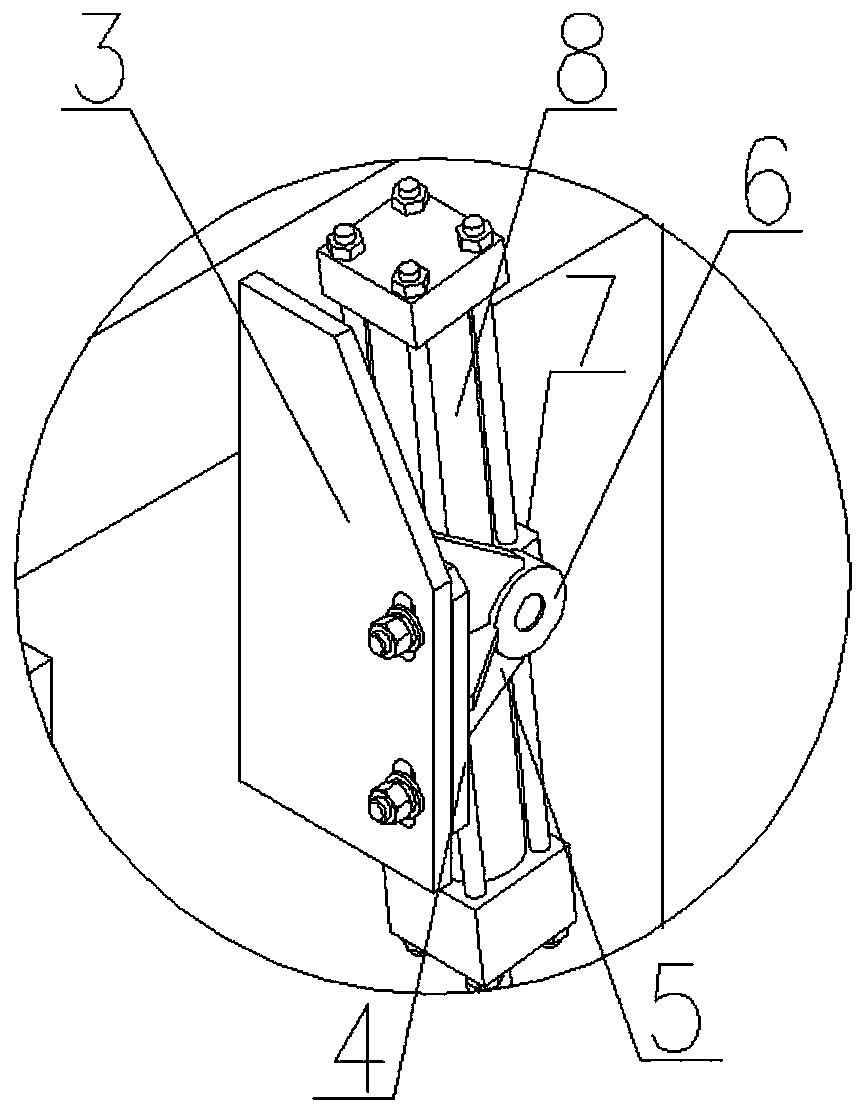

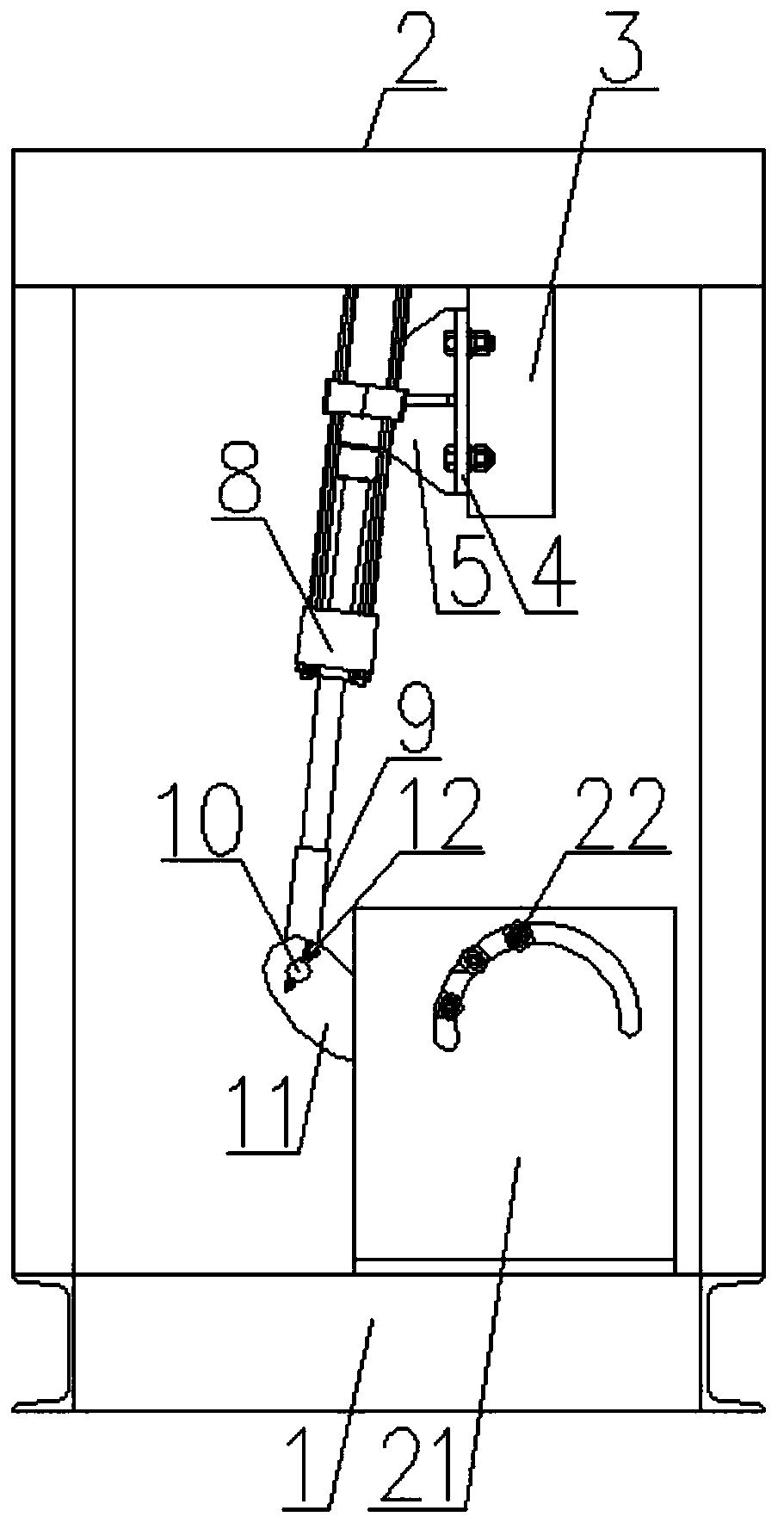

[0018] Basic as attached figure 1 and image 3 Shown: Anode vertical mold physical slag separation casting device, including frame 1, frame 1 is enclosed and welded by four channel steels to form a closed rectangular frame, and three channel steels are welded in pairs on the rear end of the rectangular frame. The formed support frame 2 is welded with a mounting plate 3 on the support frame 2 (such as figure 2 shown), the mounting plate 3 is bolt-connected with a connecting plate 4, and the connecting plate 4 is integrally formed with a trapezoidal support plate 5 and a support column 6 located on the upper part of the support plate 5, and the front and rear sides of the support plate 5 are symmetrically welded with reinforced The rib plate, the right end of the rib plate is welded together with the surface of the support column 6, and the support column 6 is also welded with two symmetrically arranged fixed blocks 7, and each fixed block 7 is provided with a passage for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com