Au-GSH@TiO2@PDMS composite material, and preparation method and application of Au-GSH@TiO2@PDMS composite material

A composite material, au-gsh technology, applied in catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of poor optical stability of noble metal nanoclusters , to achieve the effect of improving photostability and solving photoagglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0026] The preparation of embodiment 1Au-GSH

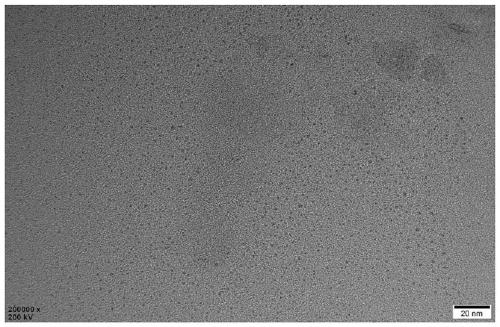

[0027] Take 20 parts of GSH, 10 parts of HAuCl 4 In a 250mL round-bottomed flask, after stirring at room temperature for 2 hours, Au-GSH complexes are formed, and the solution becomes clear at this time, then the reaction is transferred to an oil bath, heated to 70°C, and the reaction is continued for 24 hours to synthesize brown-yellow Au -GSH solution; the Au-GSH is scanned by transmission electron microscope, and its TEM picture is shown in figure 1 , figure 1 It shows that the present invention successfully synthesizes ultra-small Au-GSH clusters with a size of 1-3nm.

Embodiment 2

[0028] Example 2TiO 2 preparation of

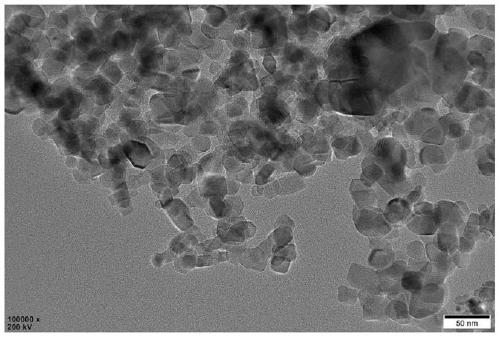

[0029]Take 40 parts of isopropanol, 40 parts of isopropanol, and 5 parts of n-tetrabutyl titanate, add them into a 50mL autoclave, and switch to a 180°C oven for 12 hours to produce white, amorphous TiO 2 The particles were washed by centrifugation with 50 parts of isopropanol, and dried at 60°C. Finally, the white TiO 2 The particles were placed in a tube furnace for high-temperature crystallization at a temperature of 450°C, a heating rate of 5°C / min, and a time of 2h to prepare crystallized photocatalyst TiO 2 particles; the TiO 2 Particles were scanned by transmission electron microscope, and the TEM images are shown in figure 2 , figure 2 Show, the present invention successfully prepares TiO 2 Nanoparticles, whose particle size is uniform.

Embodiment 3

[0030] Example 3Au-GSH@TiO 2 Preparation of composite materials

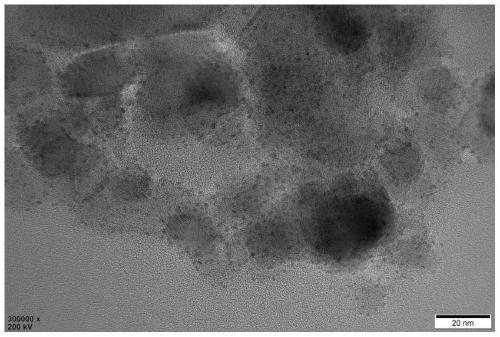

[0031] Get 100 parts of crystallization TiO prepared by embodiment 2 2 Particles, 1 part of Au-GSH prepared in Example 1, 250 parts of water in a 500mL beaker, then adjust the pH to 4 with sulfuric acid and sodium hydroxide, and stir at room temperature for 24h to prepare Au-GSH@TiO 2 composite material. For the Au-GSH@TiO 2 The composite material was scanned by transmission electron microscope, and its TEM image is shown in image 3 , image 3 It shows that the present invention has successfully prepared Au-GSH@TiO 2 Composite materials, ultra-small Au-GSH clusters uniformly loaded on TiO 2 nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com