Method for Measuring Surface-Interface Mass Transfer Coefficient and Pore Diffusion Coefficient of Porous Media

A technology of porous media and mass transfer coefficient, applied in the field of measurement, can solve the problems of large error and unclear physical meaning of mass transfer coefficient of porous media, and achieve the effect of improving performance, speeding up implementation progress and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

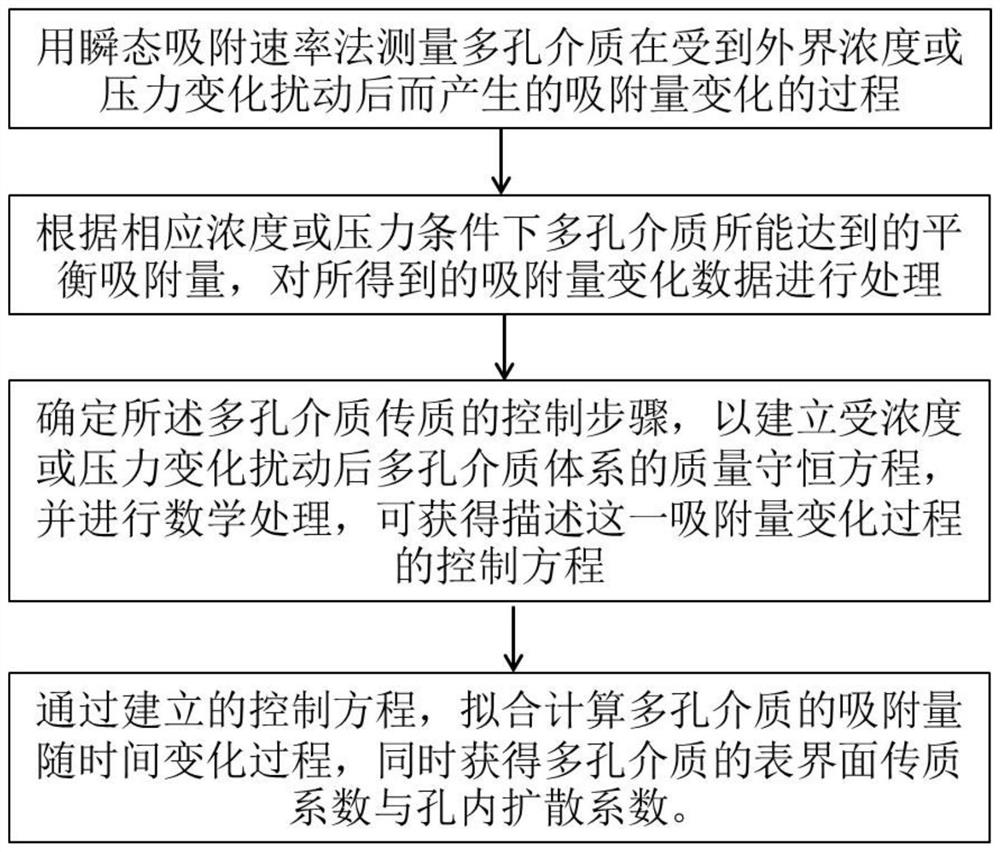

Method used

Image

Examples

Embodiment 1

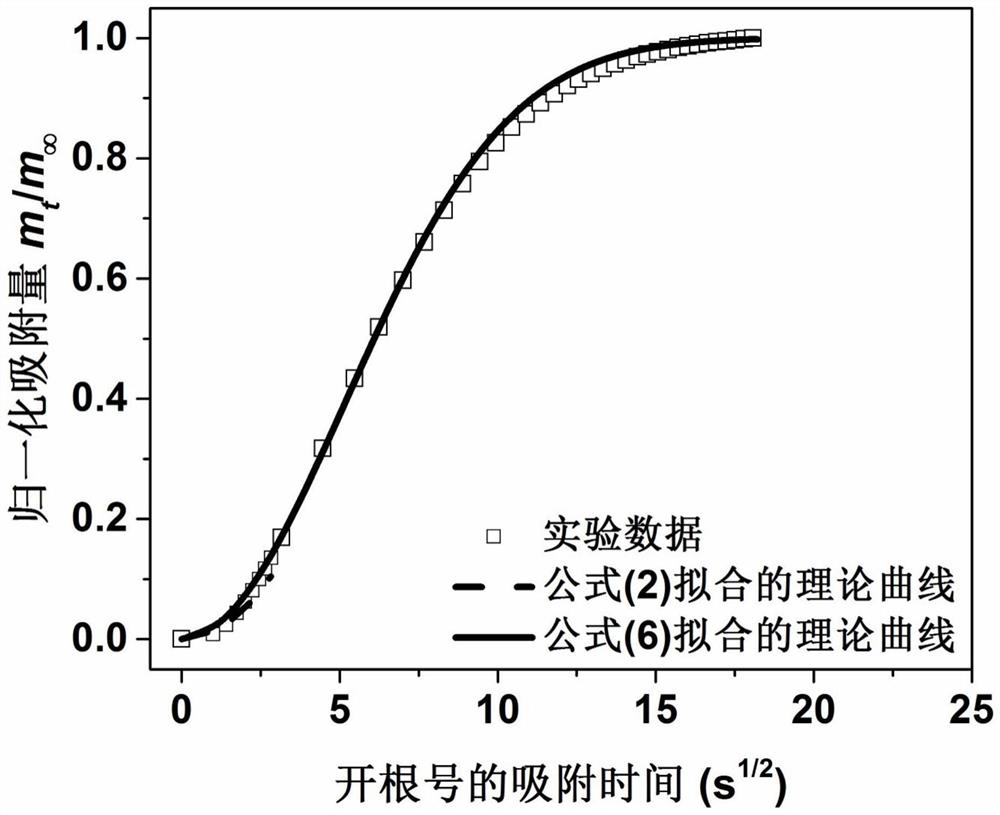

[0051] In Example 1, the change of the weight of the SAPO-34 molecular sieve catalyst (with an average characteristic length of crystals of 8 microns) with time was measured by a microbalance to obtain the relationship of the change of the adsorption amount with time. In Example 2, the relationship between the adsorption amount and the time was obtained by detecting the change of the concentration of the atmosphere in which the SAPO-34 molecular sieve catalyst (the average characteristic length of the crystal is 5 microns) with time. In Example 3, the relationship of the adsorption amount with time was obtained by detecting the change of the infrared light intensity at the characteristic peak of the infrared spectrum by the SAPO-34 molecular sieve catalyst (the average crystal characteristic length of 50 microns) by infrared spectroscopy. In Example 4, the change of the weight of the SAPO-34 molecular sieve catalyst (the average characteristic length of crystals is 2 microns) w...

Embodiment 2

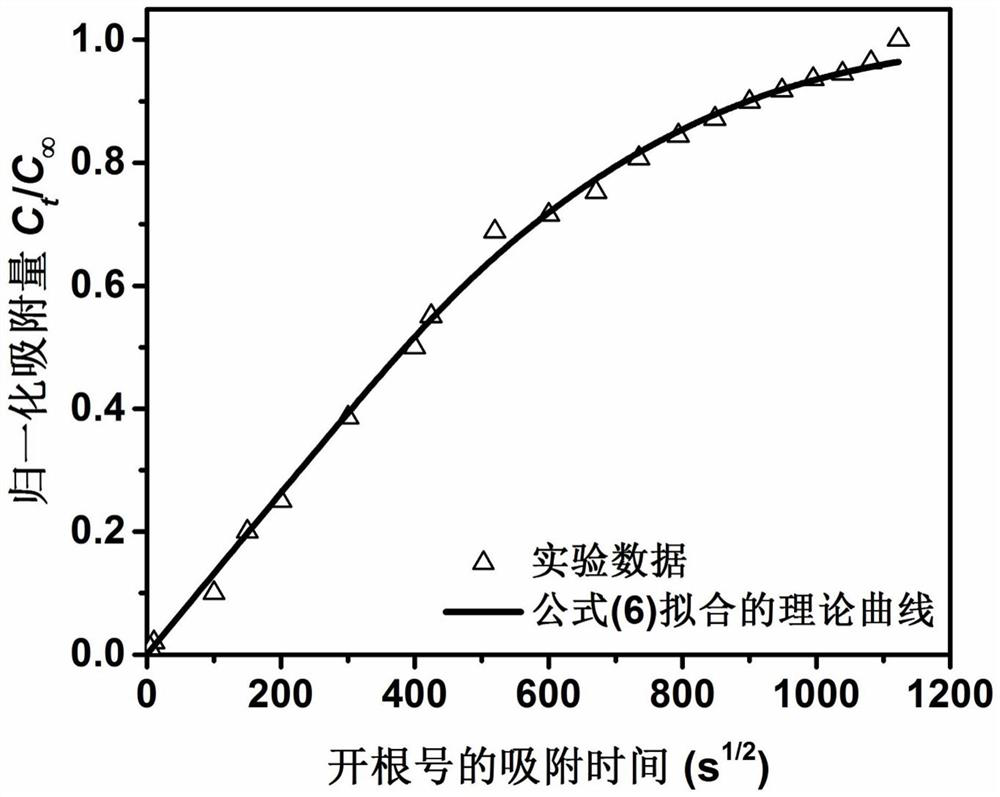

[0055] Before starting to measure the mass transfer performance of SAPO-34 molecular sieve catalyst (the average crystal characteristic length is 5 microns), it is necessary to pre-mix the adsorption sample cell with a nitrogen atmosphere containing 10% n-propanol saturated steam, and set the adsorption sample. The temperature of the cell was 70°C. The SAPO-34 molecular sieve catalyst synthesized in the laboratory was loaded into the sample cell tray to detect the concentration change of the adsorption atmosphere after the SAPO-34 molecular sieve catalyst entered the sample cell atmosphere. Before testing the transient adsorption rate curve, the sample of SAPO-34 molecular sieve catalyst needs to be pretreated by vacuum dehydration, and the dehydrated SAPO-34 molecular sieve catalyst is sent to the adsorption sample cell for the adsorption of n-propanol gas. Under this condition, it is equivalent to a given pressure pulse of 1.2 mbar, the used pressure increase rate is about 1...

Embodiment 3

[0057] The SAPO-34 molecular sieve catalyst synthesized in the laboratory (the average crystal characteristic length of 50 microns) was loaded into the in-situ infrared sample cell to detect the change of the methanol adsorption characteristic peak intensity after the SAPO-34 molecular sieve catalyst adsorbed methanol molecules. Before testing the transient adsorption rate curve, the sample of SAPO-34 molecular sieve catalyst needs to be pretreated by vacuum dehydration. Under the set dehydration conditions, scan the infrared spectrum of the SAPO-34 molecular sieve catalyst until the SAPO-34 obtained by scanning The test of the transient adsorption rate curve can only be carried out after the infrared spectrum of the molecular sieve does not change with time. Methanol was selected as the adsorption guest molecule, and the temperature of the SAPO-34 molecular sieve catalyst was kept at 25 °C, the pressure reached after the given pressure controller pulse was 1.2 mbar, and the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com