Strain type two-component surface frictional resistance measuring balance

A surface friction and two-component technology, applied in the field of wind tunnel testing, can solve the problems of small measuring balance, low measurement resolution, single-component measurement, etc., and achieve the effect of small size, high resolution and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

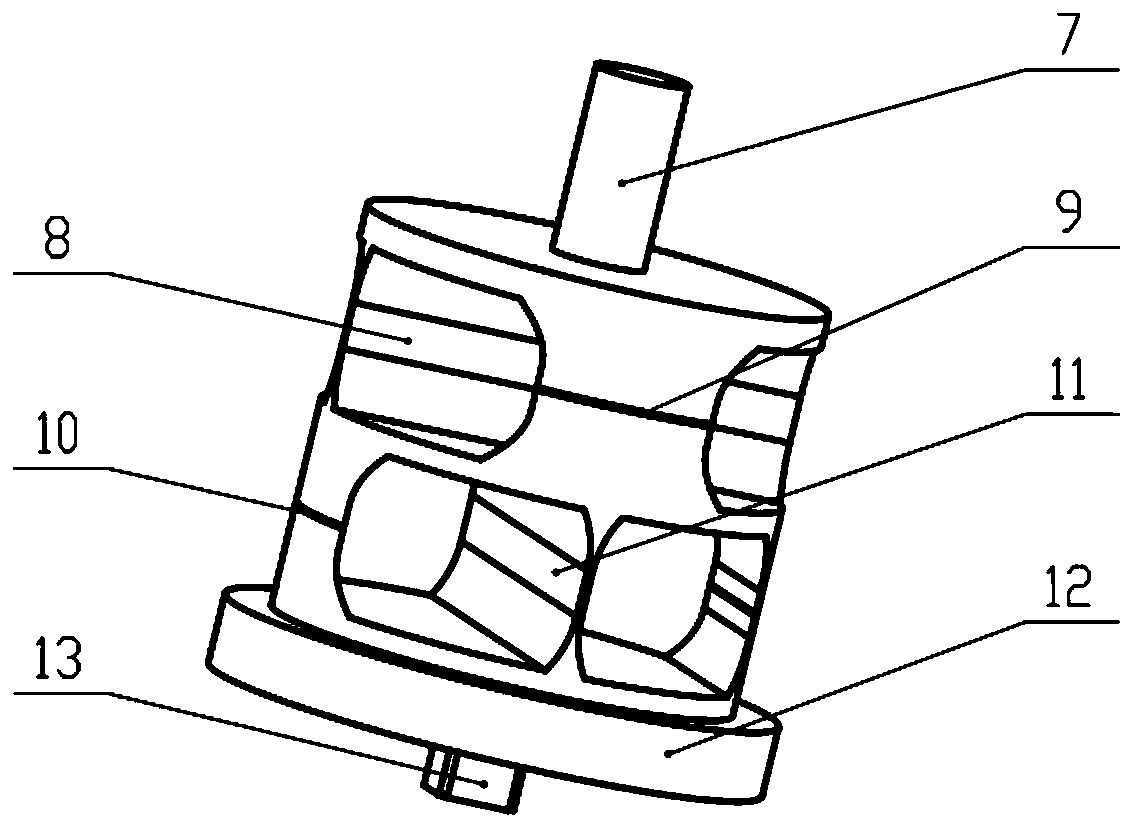

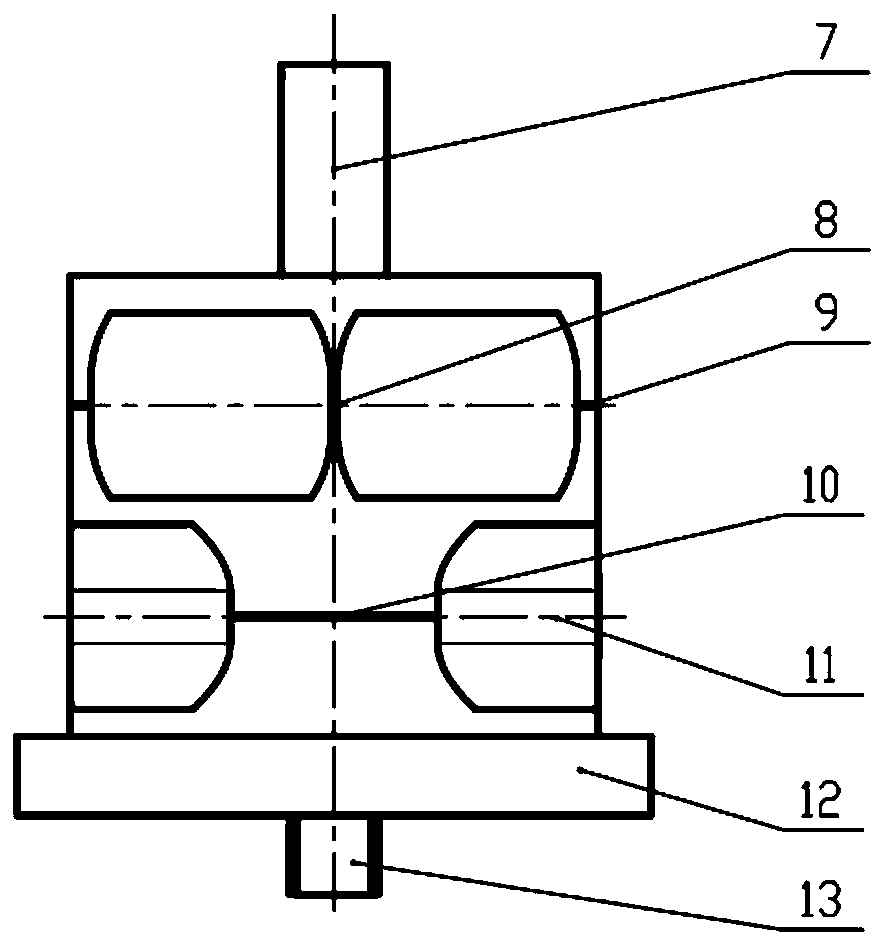

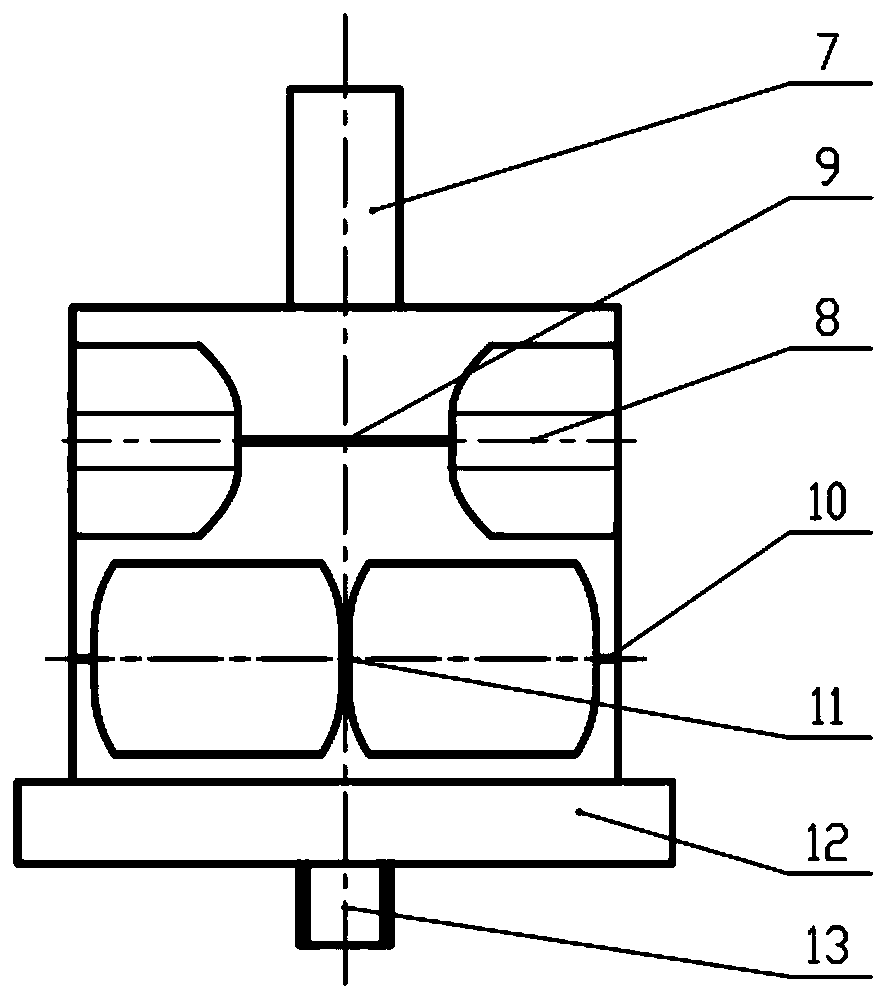

[0045] Such as Figure 7As shown, the surface friction resistance measurement balance 3 of the present embodiment is processed with a supporting balance protection case 6, and the balance protection case 6 is a closed cylinder at the bottom, covering the surface friction resistance measurement balance 3 from bottom to top, and the surface friction resistance measurement The balance 3 and the balance protective case 6 are connected by surface fit, positioned by the rectangular positioning block 13, and tightened and fixed by the bottom screw; Connect the measuring surface 2 to the connecting piece 4, then install the balance protective case 6 into the outer shell of the aircraft to be measured and adjust the gap around the measuring surface. You can adapt to different measuring surfaces 2 and measuring lines by using connecting pieces 4 of different sizes According to the model or the internal structure of the aircraft, it is drawn from a suitable position on the bottom or side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com