Large-component three-dimensional measurement method based on line structured light and industrial robot

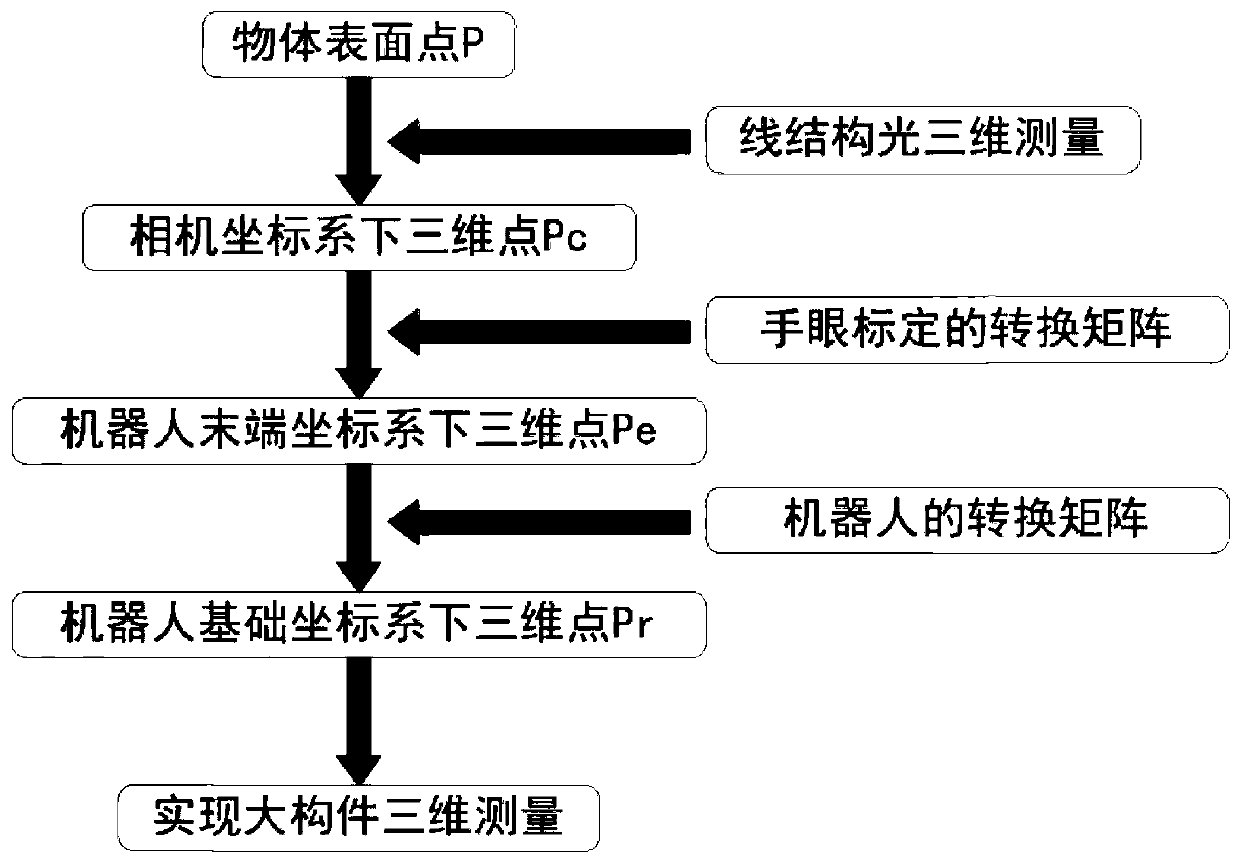

An industrial robot, three-dimensional measurement technology, applied in the field of computer vision, can solve the problems of poor control of splicing error, single splicing method, complex calibration process, etc., to achieve the effect of low measurement environment requirements, simplified calibration process, and broad development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

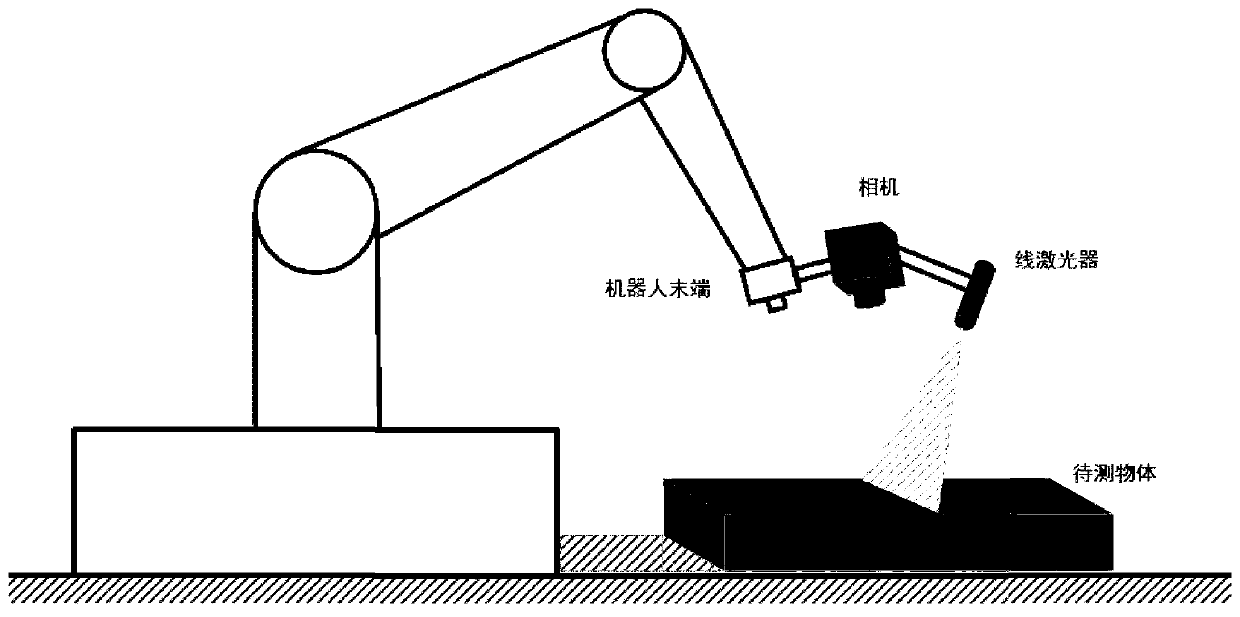

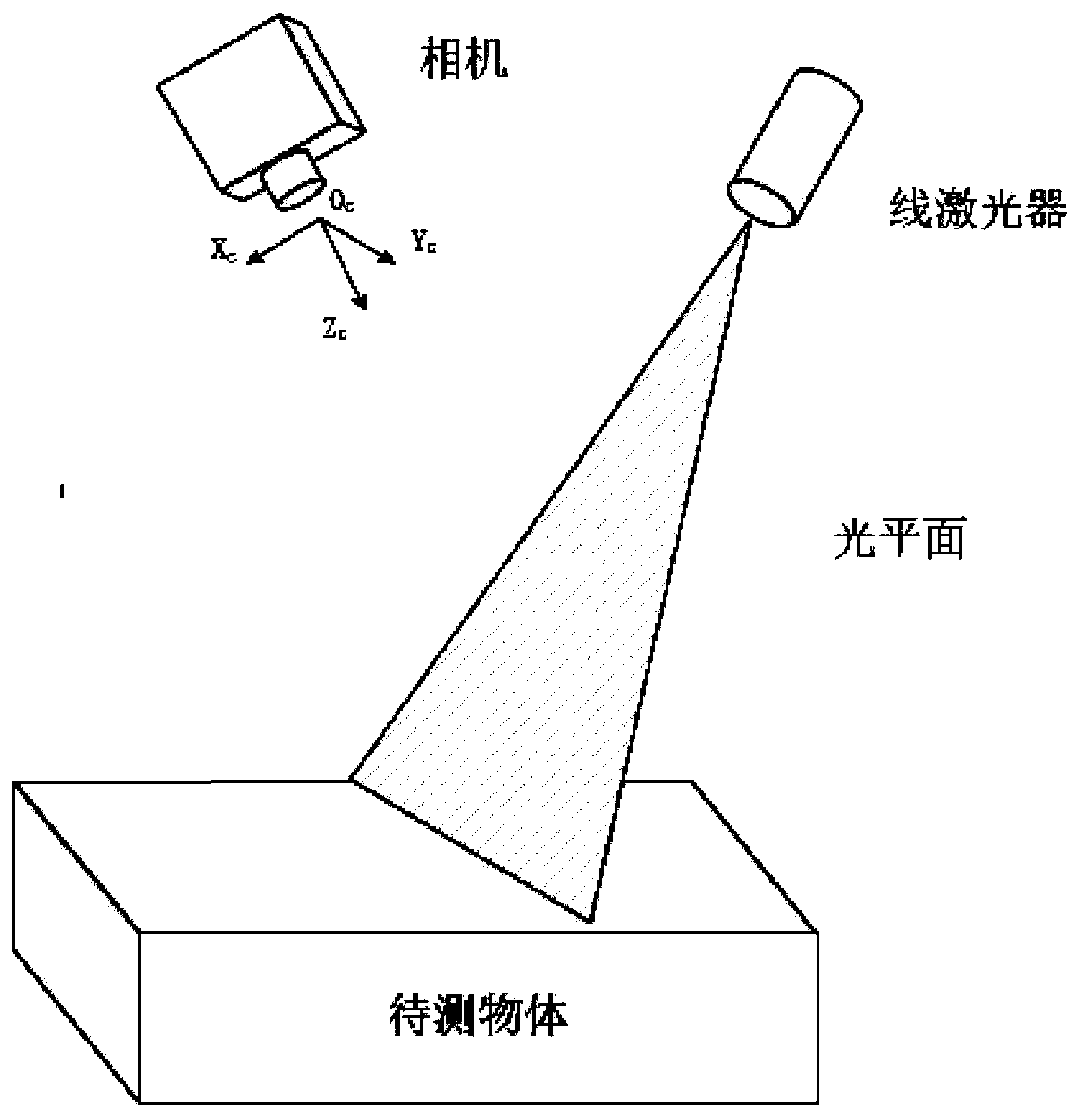

[0056] The large component three-dimensional measurement system of this embodiment is composed of industrial robots, cameras, line lasers and computers. The robot is the ERER-MA02010-A00-C model industrial robot of Yaskawa. The relevant parameters of the robot are as follows: The positioning accuracy is 0.08mm, the vertical elongation is 3649mm, and the horizontal elongation is 2010mm. The camera is an industrial camera, the model is Basler acA1920-40gm, and the laser is a line laser with 200mw power and 650nm wavelength. The camera and line laser are mounted on the end of the robot to form a line structured light 3D measurement system. The computer is connected to the camera and the control cabinet of the robot to obtain the line laser image and the attitude data of the robot. The three-dimensional measurement method of large components includes the following steps:

[0057] Step 1: Fix the camera 1 and the laser at the end of the Yaskawa robot, and take another camera 2 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com