Air-water heat exchanger for cooling equipment

A technology for cooling equipment and heat exchangers, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as hidden safety hazards of the whole equipment, and achieve the effect of improving safety performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

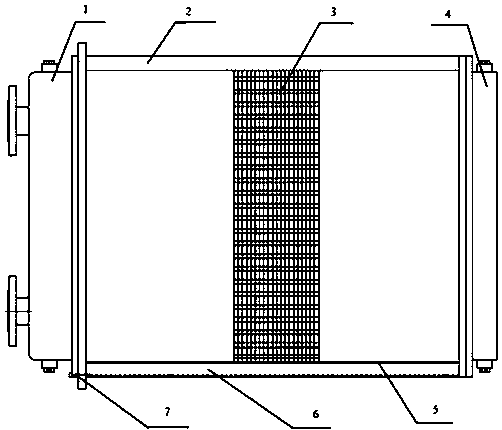

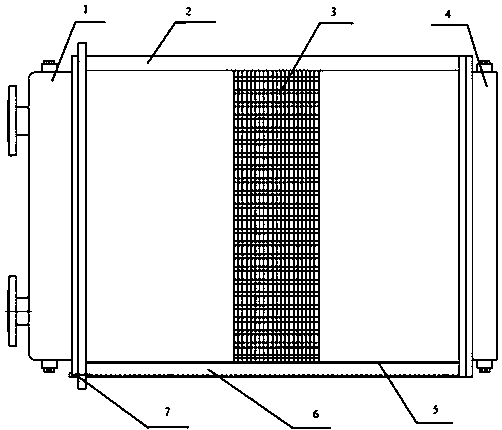

[0015] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

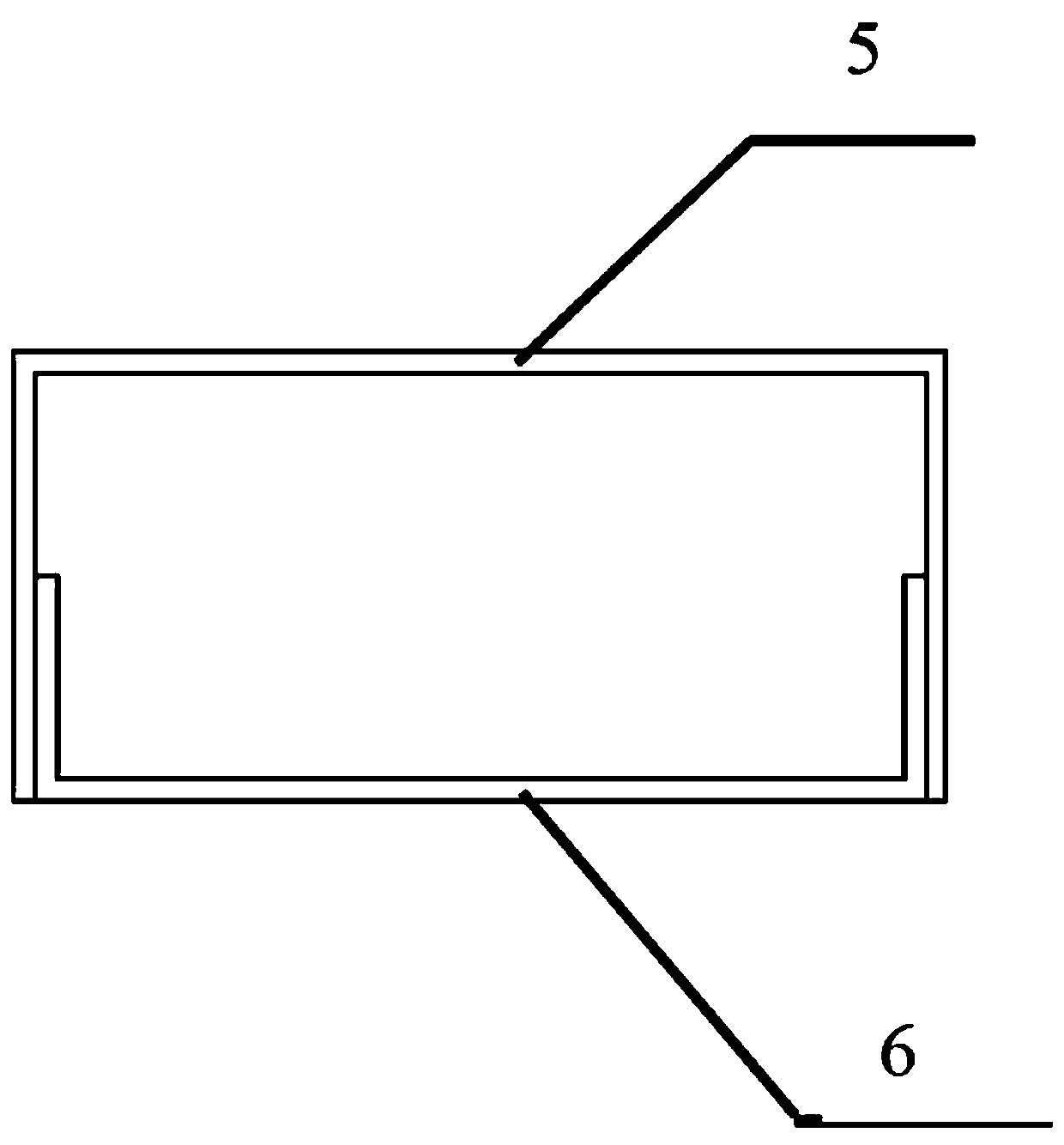

[0016] As shown in the figure, an air-to-water heat exchanger for cooling equipment includes a box body 2, and the front and rear sides of the box body are provided with air inlets and air outlets for heat exchange in and out of air. There are left and right water chambers 1 and 4 on both sides of the box body. The cooling water inlet and cooling water outlet are installed on the end surface of the left water chamber 1. The cooling water inlet is located above the cooling water outlet, and a partition is set in the middle of the left water chamber. , the cooling water inlet and outlet are separated into two independent cavities, the heat exchange core 3 is installed in the box body 2, and the heat exchange core 3 is a heat exchange tube group composed of multiple heat exchange tubes. Covered with fins, the two ends of each heat exchange tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com