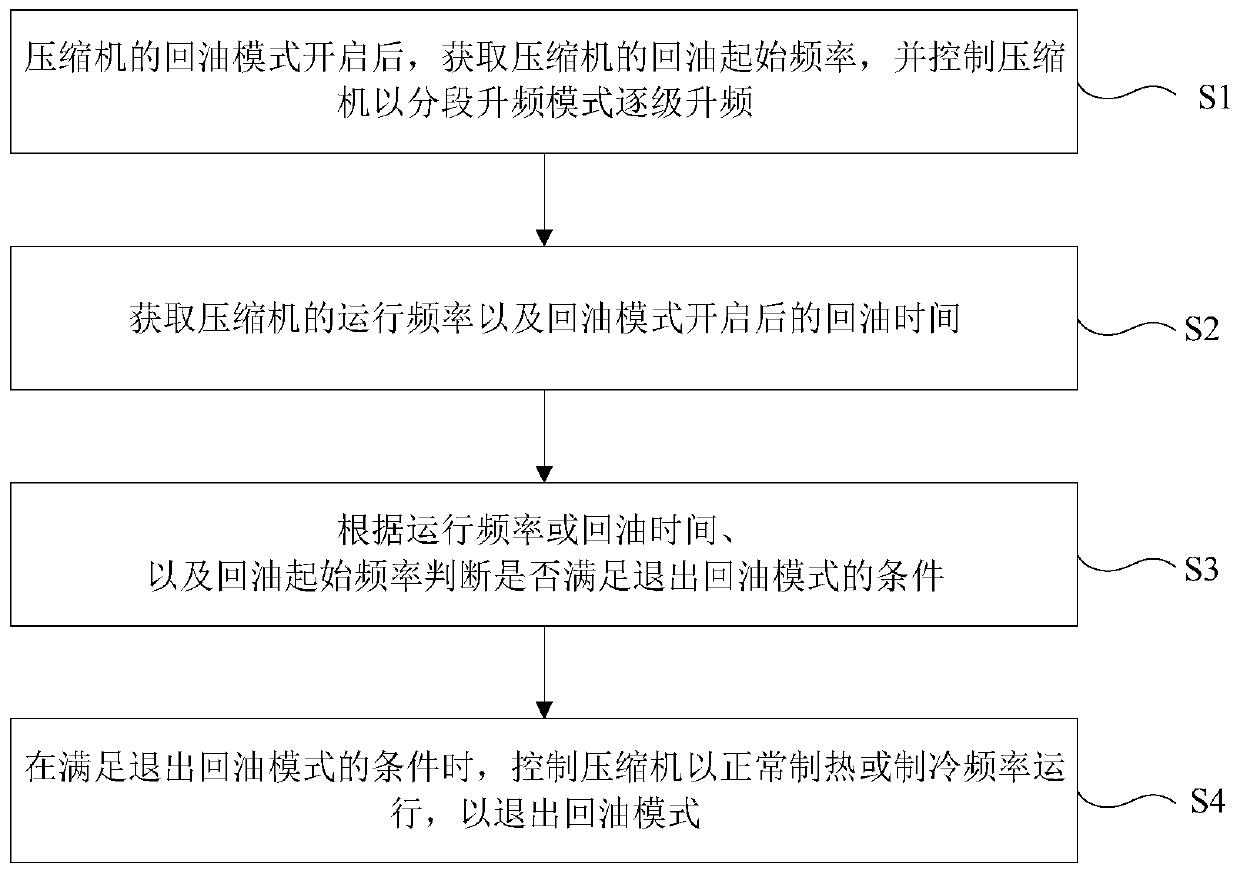

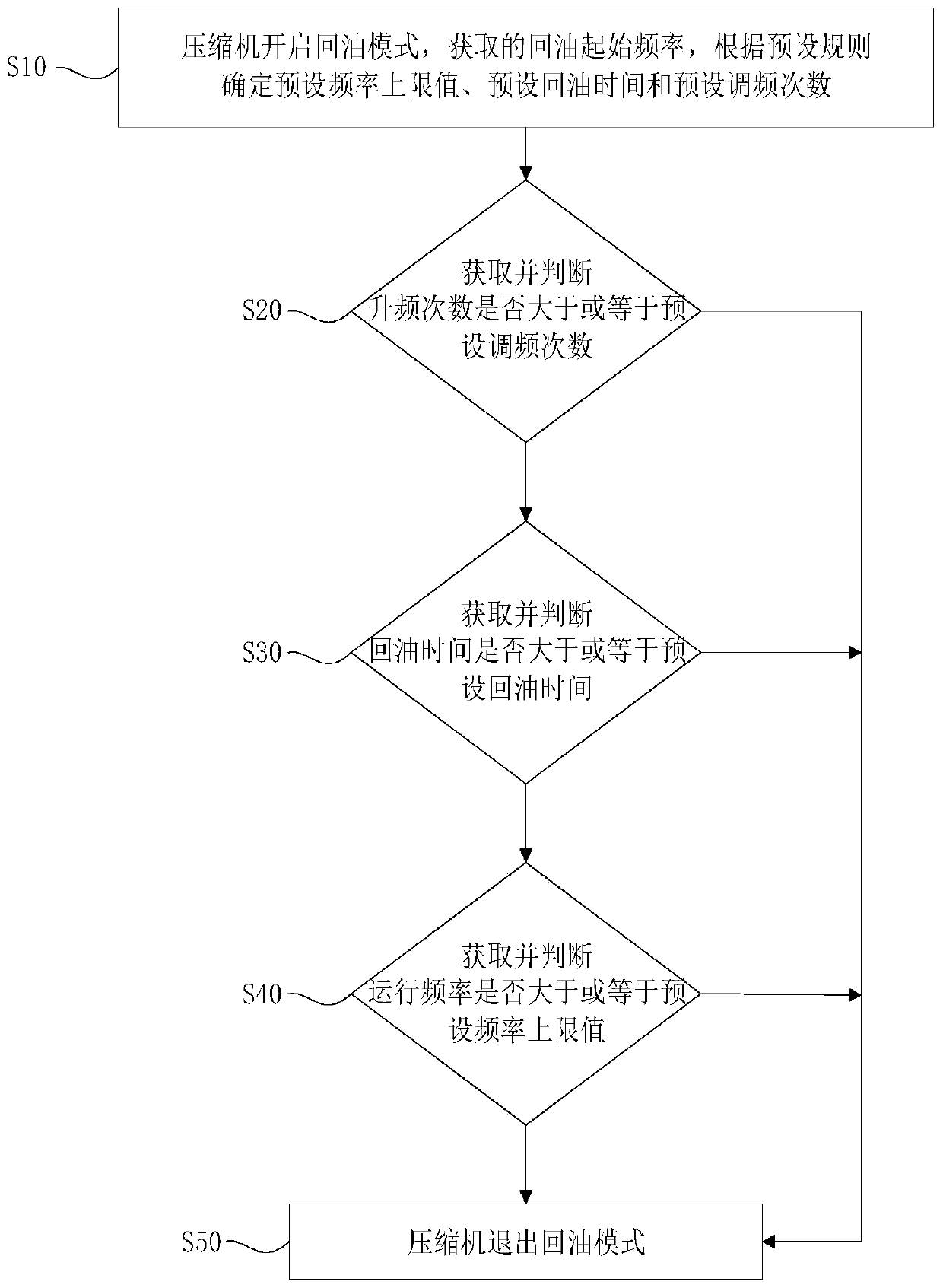

Oil return control method and device for compressor and air conditioner

An oil return control and compressor technology, applied in compressors, refrigerators, refrigeration components, etc., can solve the problems of reducing the energy efficiency of the whole machine, unable to accurately judge the oil return, and compressor oil shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0038] In addition, if there are descriptions related to "first", "second", etc. below, the descriptions of "first", "second", etc. are only for descriptive purposes, and cannot be understood as indicating or implying their relative importance nature or implicitly indicate the number of technical features indicated. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of these features.

[0039] The high-speed operation of the air conditioner compressor in the prior art will take out part of its internal lubricating oil, so an oil separator is installed at its outlet, and most of the oil is intercepted by the oil separator and returned to the compressor through the oil return capillary; But there is still a part of lubricating oil that will be brought into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com