Compressor oil return control method, system and air conditioner

A technology of oil return control and compressor, which is applied in the direction of compressors, refrigerators, refrigeration components, etc., can solve the problems of compressor protection and shutdown, and achieve the effect of avoiding shutdown protection, precise control process, and high degree of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

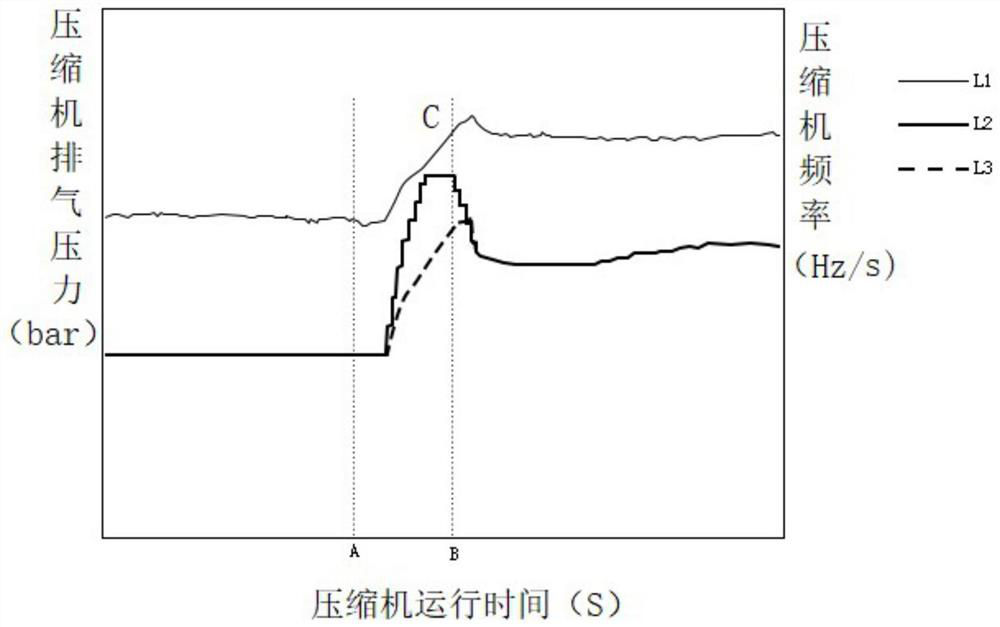

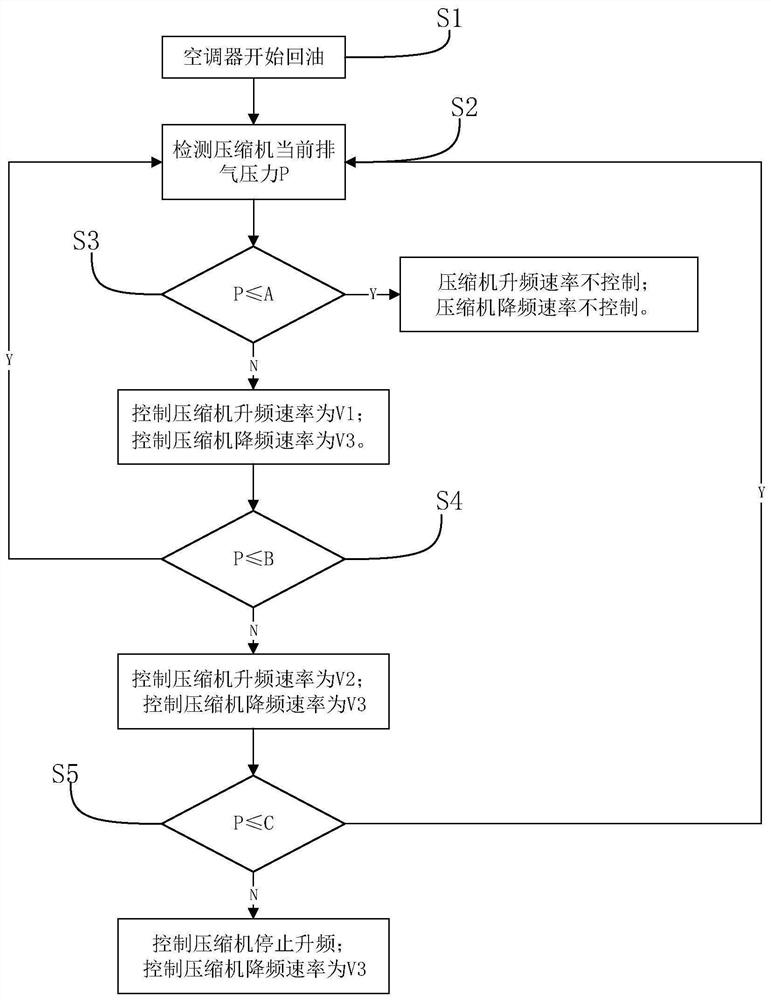

[0039] Such as figure 2 As shown, a compressor oil return control method includes steps:

[0040] S1, the air conditioner starts to return oil;

[0041] S2, detecting the current discharge pressure P of the compressor;

[0042] S3, judging whether the current discharge pressure P of the compressor is ≤ a preset threshold A? If yes, neither control the frequency increase rate nor the frequency decrease rate of the compressor; if not, control the frequency increase rate of the compressor to be V1, and the frequency decrease rate to be V3, and continue to execute step S4;

[0043] S4, judging whether the current discharge pressure P of the compressor is ≤ a preset threshold B? If yes, re-execute step S2; if not, control the frequency up rate of the compressor to be V2 and the frequency down rate to be V3, and continue to perform step S5;

[0044] S5, judging whether the current discharge pressure P of the compressor is ≤ a preset threshold C? If yes, re-execute step S2; if no...

Embodiment 2

[0055] A compressor oil return control method, comprising the steps of:

[0056] S1, the air conditioner starts to return oil;

[0057] S2, detecting the current discharge pressure P of the compressor;

[0058] S3, judging whether the current discharge pressure P of the compressor is ≤ a preset threshold A? If yes, do not control the frequency increase rate of the compressor; if not, control the frequency increase rate of the compressor to be V1, and proceed to step S4;

[0059] S4, judging whether the current discharge pressure P of the compressor is ≤ a preset threshold B? If yes, re-execute step S2; if not, control the frequency increase rate of the compressor to be V2, and continue to execute step S5;

[0060] S5, judging whether the current discharge pressure P of the compressor is ≤ a preset threshold C? If yes, re-execute step S2; if not, control the compressor to stop increasing the frequency and run at the rate of V3 until the current discharge pressure P of the c...

Embodiment 3

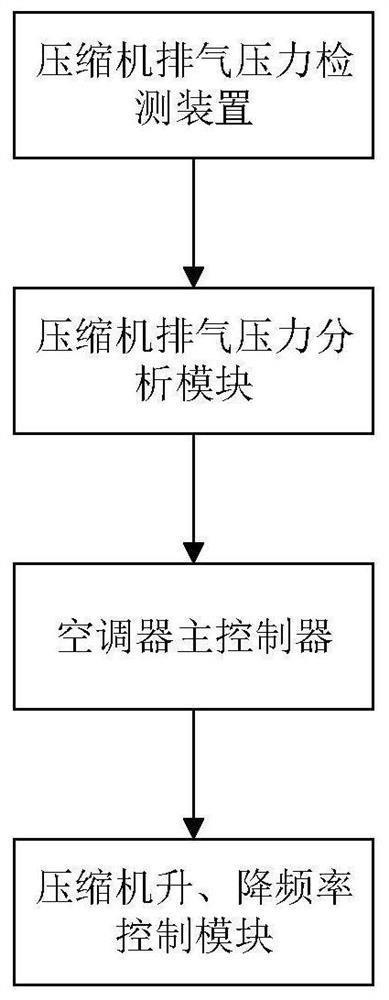

[0062] Such as image 3 As shown, a compressor oil return control system includes:

[0063] A compressor discharge pressure detection device, the compressor discharge pressure detection device can detect the current discharge pressure P of the compressor, and transmit the detected current discharge pressure P of the compressor to the compressor discharge pressure analysis module;

[0064] Compressor discharge pressure analysis module, the compressor discharge pressure analysis module can compare the current discharge pressure P of the compressor it receives with the preset thresholds A and B in the air conditioner according to the above-mentioned compressor oil return control method Compare with C, and transmit the comparison result to the main controller of the air conditioner;

[0065] The main controller of the air conditioner, the main controller of the air conditioner can send the compressor frequency increase and decrease control command to the compressor frequency incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com