System and method for improving integrity of cased wellbores

A cased well and integrity technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve limited and casing damage problems, reduce damage, reduce magnitude and risk, and reduce integrity The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

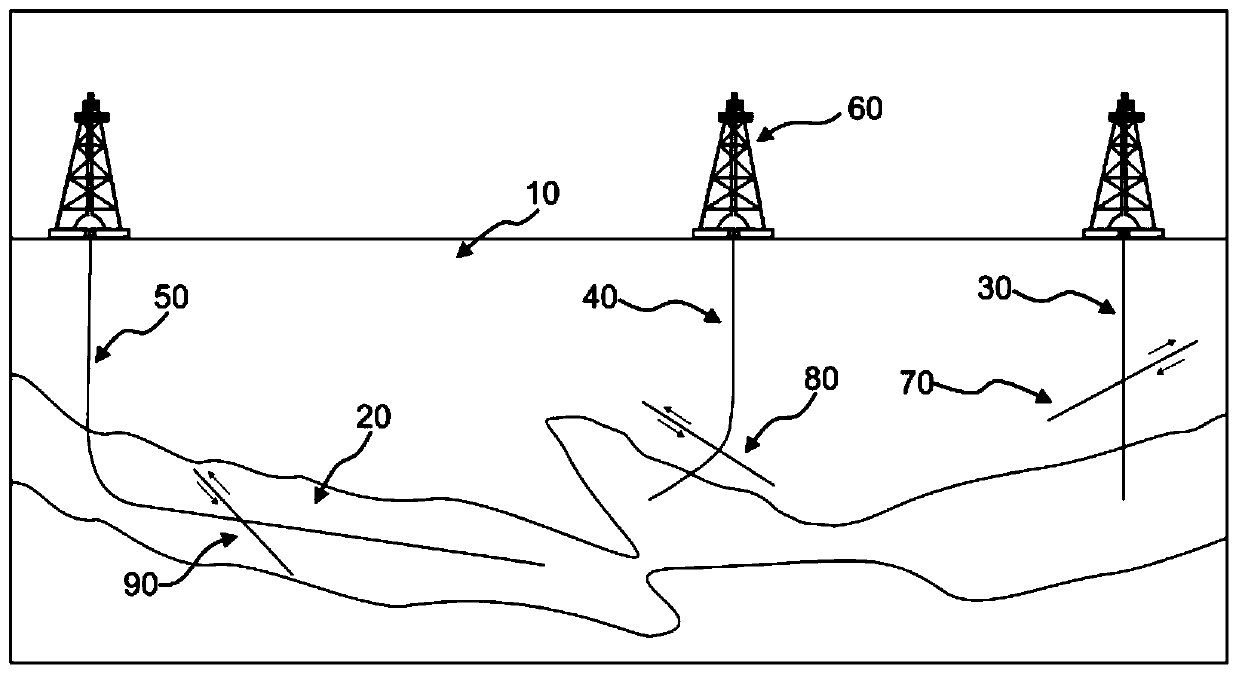

[0112] In one of the embodiments disclosed by the present invention, figure 1 A schematic diagram of a system 10 for producing fluids from or injecting fluids into a formation is depicted. System 10 may include formation 20 , wells 30 , 40 , 50 and fluid production or injection facility 60 . Depending on ground conditions, geological conditions and economic prospects, vertical wells 30, deviated wells 40 or horizontal wells 50 may be drilled. The deviated well 40 is initially drilled vertically downward and then deviated towards the formation 20 . The horizontal well 50 is drilled using a rotary steerable method, and the resulting deviated wellbore trajectory can be maintained within the formation 20 . The borehole may intersect one or more weak surfaces 70, 80, 90 that induce fault slip due to production or injection operations disturbing the stress field.

Embodiment 2

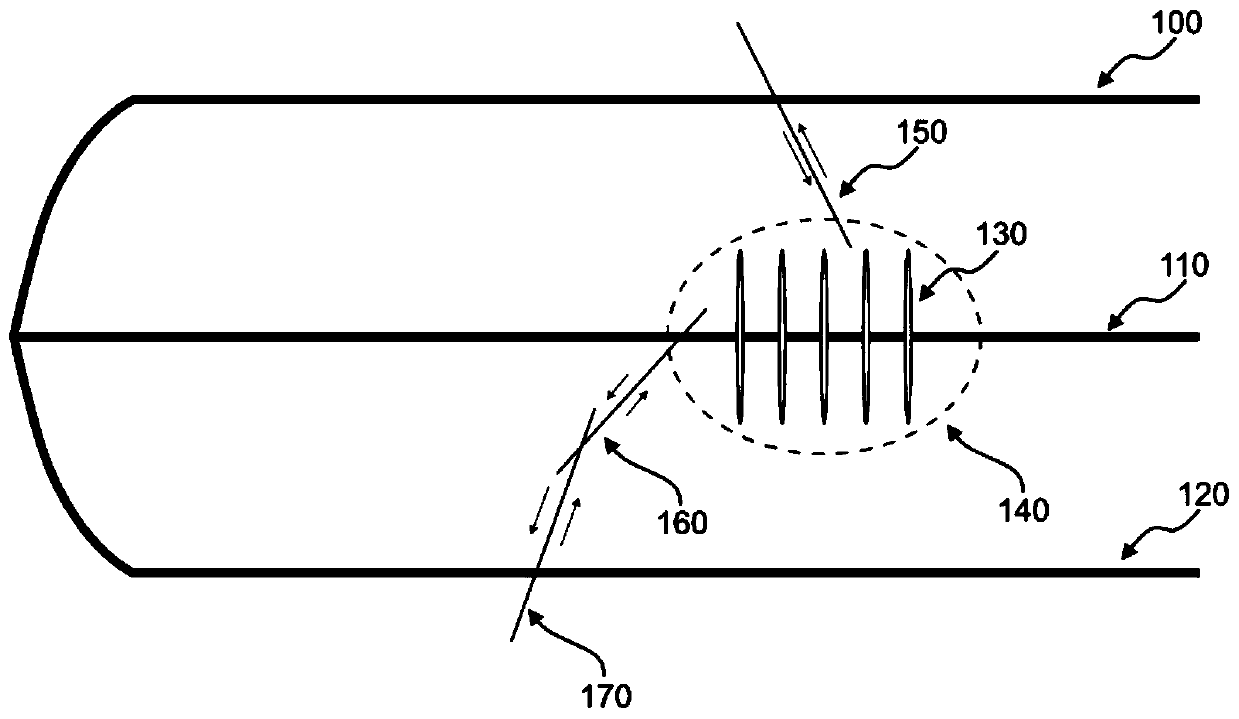

[0114] In one of the embodiments disclosed by the present invention, figure 2 Schematic depicting fault reactivation due to hydraulic pressure work in a multi-well platform. As shown, multiple horizontal wells 100, 110, and 120 are drilled from a single drilling rig. During hydraulic fracturing, fluid is injected into the horizontal well 110 to initiate and propagate one or more hydraulic fractures 130 within the rock formation containing the wellbore. Furthermore, hydraulic fractures 130 may be planar, or may interact with natural fractures to form complex fracture networks within reservoir stimulated volume 140, depending on in situ stresses and geological conditions. Pre-existing faults 150 and 160 may directly interact with hydraulic fractures 130 or contact reservoir stimulated volume 140 to induce stress or pore pressure changes to initiate reactivation. Slippage of fault 150 may cause damage to casing deployed and consolidated within horizontal well 100 . Likewise, ...

Embodiment 3

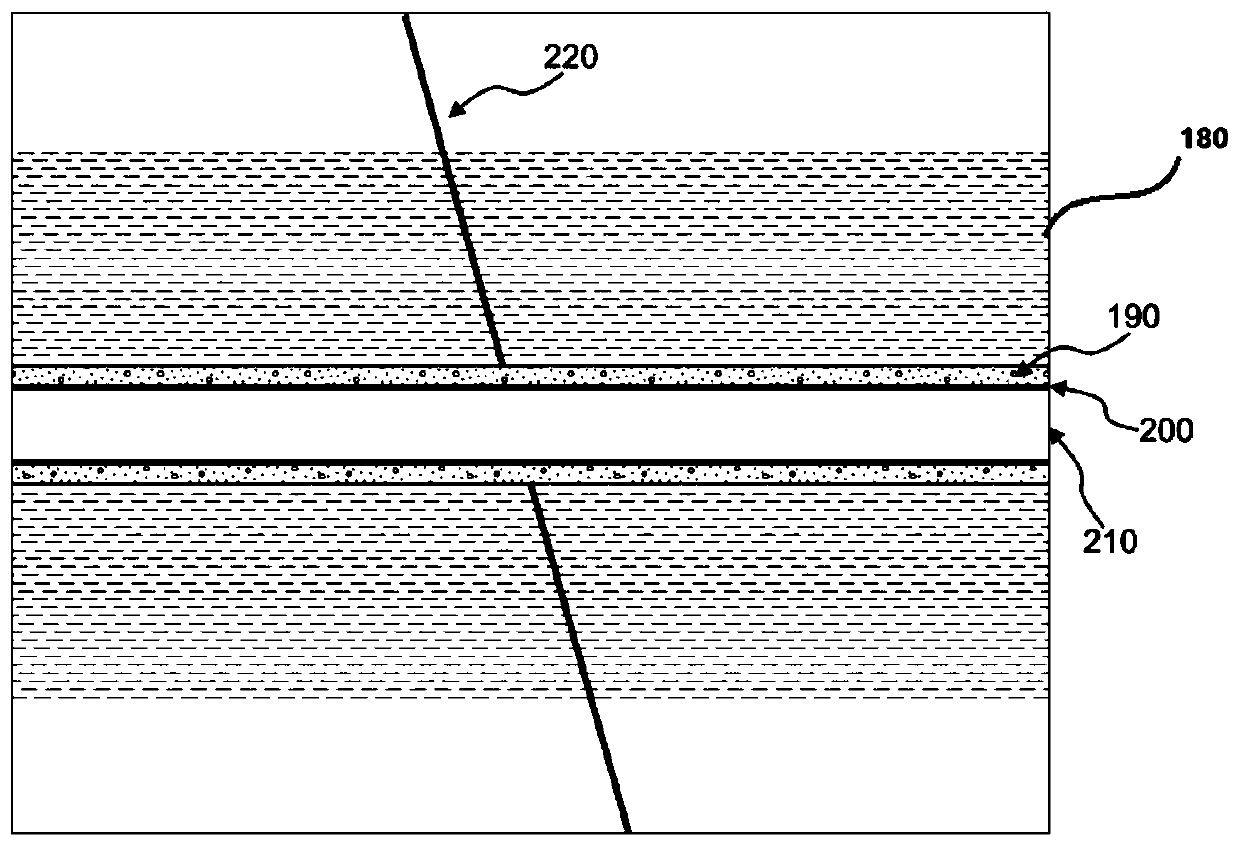

[0116] In one of the embodiments disclosed by the present invention, image 3 A schematic cross-sectional view of a cased wellbore 210 intersecting a fault 220 is depicted. When a well is drilled, the portion of the wellbore where no casing has been placed and consolidated is called the "open hole". The casing 200 is a special steel pipe for oil and gas wells. After drilling to the target depth, it is lowered into the open wellbore, and then the casing 200 is consolidated in place with the cement sheath 190 . Consolidating casing in oil and gas wells is critical to maintaining wellbore stability, preventing contamination of drinking water zones, isolating different formations, and working downhole. Cased wellbore 210 may intersect one or more weak surfaces, such as fault 220 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com