A directional drilling tool and drilling method for preventing and controlling water holes under high water pressure jacking water in coal mines

A high water pressure, directional drilling technology, applied in the field of drilling, can solve the problems of poor water control effect, large amount of auxiliary engineering, shortening, etc., to improve the effective utilization of hydraulic energy, reduce "reactive" load, and improve mechanical drilling speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

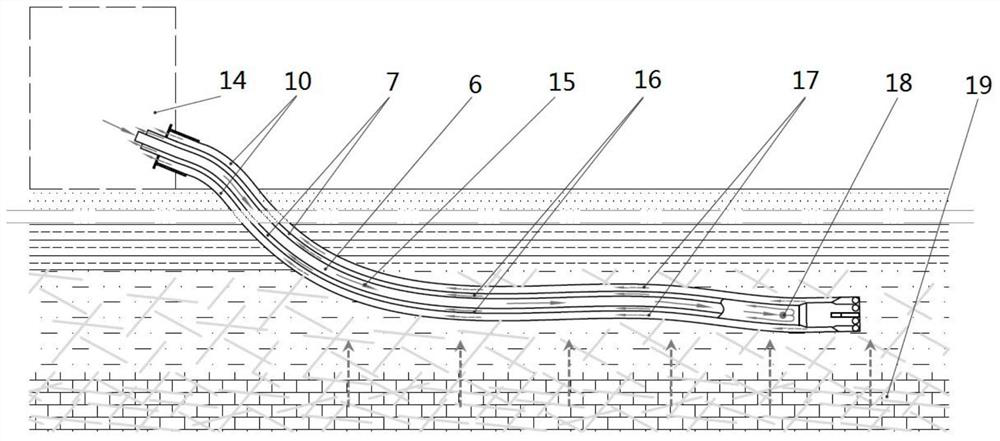

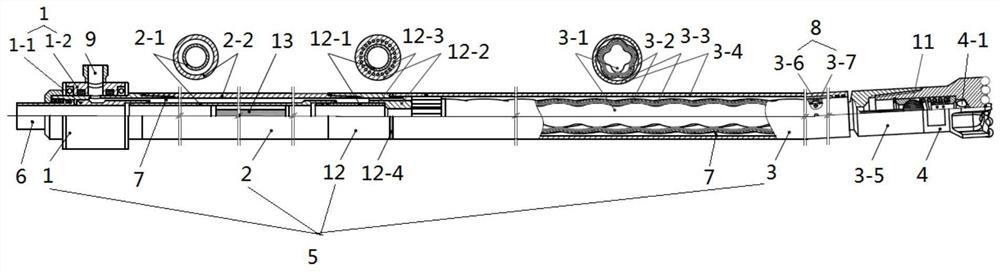

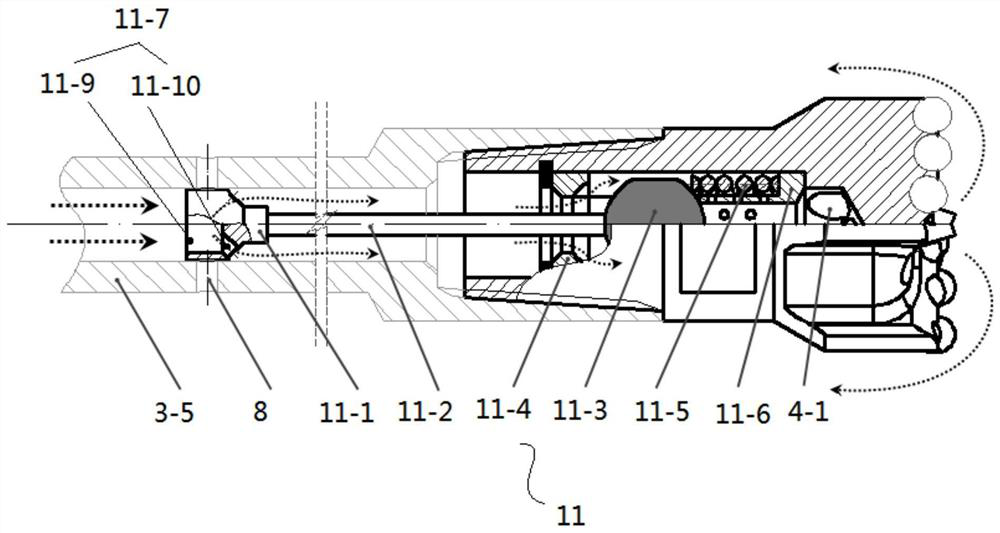

[0047] like figure 2 As shown, the present embodiment discloses a directional drilling tool for preventing and controlling water holes in coal mines with high water pressure and jacking water. The central flow channel 6 communicates with the bottom flow hole 4-1 of the directional drill bit. An inner annular flow channel 7 is arranged around the outside of the drill string body 5, and one end of the inner annular flow channel 7 close to the directional drill bit 4 communicates with the central flow channel 6 through the first bypass flow channel 8 provided on the drill string body 5; The other end of the inner annular channel 7 communicates with the outside of the drilling tool through a second bypass channel 9 provided on the inner annular channel.

[0048] In this embodiment, the drill string body 5 includes a double-channel water feeder 1 having a central channel 6 and an inner annular channel 7 , a double-wall drill pipe 2 and a double-wall single-curved screw motor 3 co...

Embodiment 2

[0061] This embodiment discloses a directional drilling method for preventing and controlling water holes in coal mines with high water pressure and top water directional drilling. The method specifically includes the following steps:

[0062] Step 1, hole drilling: According to the sealing pressure requirements and casing structure design, determine the drilling diameter and depth corresponding to the multi-layer casing, and use the conventional rotary drilling technology to construct the casing step by step from shallow to deep, from small to large For the pipe hole section, as in this embodiment, construct a φ120mm guide hole first, and then expand the hole, the second-level casing is reamed to φ193mm or more, and the third-level casing is reamed to φ220mm or more;

[0063] Step 2, lower the pipe and fix the hole: lower the casing step by step. In this embodiment, the inner diameter of the innermost casing is ≥Φ135mm; then grouting, waiting for coagulation, and pressure test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com