Multipurpose prefabricated thermal insulation board and manufacturing method and construction method of multipurpose prefabricated thermal insulation board as different walls

A multi-purpose, thermal insulation board technology, applied in thermal insulation, manufacturing tools, walls, etc., can solve the problems of insufficient wall bearing capacity, weak connection between the upper and lower floors, etc., achieve easy operation, convenient and efficient assembly, and improve fire performance and load bearing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

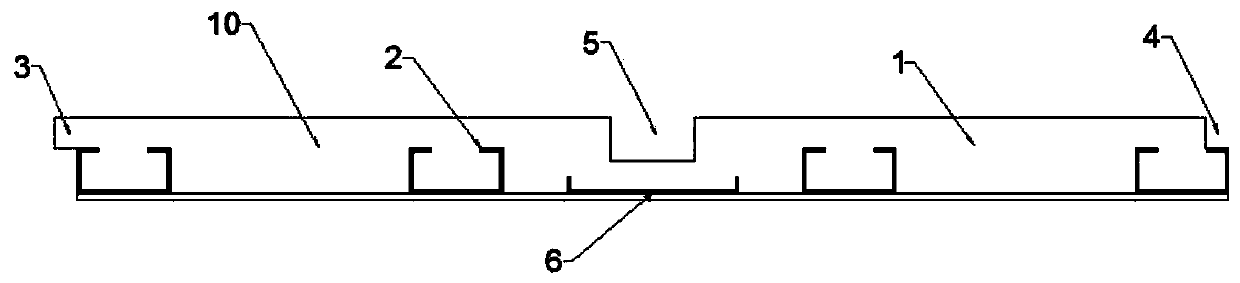

[0050] Example one: by Figure 1 to Figure 7 Given, a multi-purpose prefabricated thermal insulation board includes a board body 100, the board body 100 includes a main board 1 and a steel frame compounded together, and one end of the board body 100 has a protruding tongue and groove 3 and is in line with the protruding tongue and groove. The corresponding other end is provided with a recessed tongue 4, the steel frame includes a plurality of steel keels 2, each of the steel keels 2 is arranged in an array on the same side of the main board 1, and the steel keel is a "C" with an inner curl Shaped steel, the steel frame also includes angle steels and auxiliary heat preservation plates including slabs to form parts of a stable structure. The angle steels are located at the four long edges of the upper and lower end faces of the plate body and the sides of the slab body, and are matched with the slabs. Form a stable board frame.

[0051] On the basis of the first embodiment, each o...

Embodiment 2

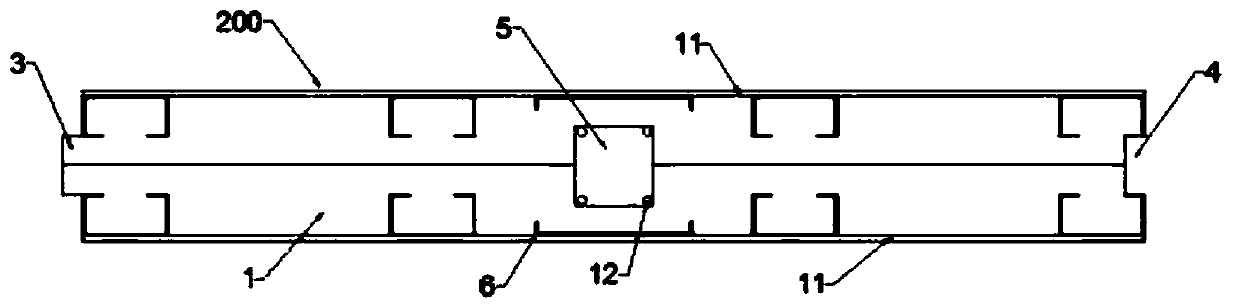

[0052] Embodiment 2: On the basis of Embodiment 1, the wallboard used for the load-bearing wall includes a load-bearing wallboard unit 200. The load-bearing wallboard unit 200 includes two mirror-arranged No. 1 board body units 10, each The No. 1 plate body unit 10 is a plate body 100 with a groove 5 and a reinforcing steel strip 6 in the middle. The No. 1 plate body unit 10 is improved on the basis of the plate body 100 and uses the same set of molds as the main board 1. The reinforced steel belt 6 and the steel keel 2 are located on the same side, the side with the steel keel 2 on each of the No. 1 plate body units 10 serves as the outer side of the load-bearing wall panel unit 200, and the two No. 1 plate body units are mirrored The groove in the middle of 10 corresponds to a cavity formed in the middle of the load-bearing wall panel unit 200. The cavity is provided with an uninterrupted concealed column 9 between each layer. The concealed column 9 increases the load-bearing ...

Embodiment 3

[0055] Embodiment 3: On the basis of Embodiment 1, a non-load-bearing wall panel with wind-resistant columns is added. The wall panel includes a second panel unit 20, and the second panel unit 20 has a plurality of recesses. The groove 5 and the plate body 100 of the reinforced steel belt 6, each of the reinforced steel belts is distributed on the side of the plate without the steel keel, and each of the grooves 5 is arranged on the side where the steel keel 2 is located and is connected with the reinforced steel The belt 6 corresponds, and the corresponding position of the wallboard becomes relatively thin after the groove is provided, so it is arranged corresponding to the reinforced steel belt to prevent the wallboard from breaking. The groove 5 is provided with a square steel pipe 18.

[0056] In the above embodiments, the main board 1 may be one of EPS boards, foam concrete boards or polystyrene particle foam concrete boards. When the prefabricated insulation board is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com