Furnace burden structure ratio for adjusting blast furnace slag MgO

A technology of charge structure and blast furnace slag, which is applied in the field of blast furnace slag, can solve the problems of affecting the basicity of sinter, needing more than 16 hours, and unsuitable ratio, so as to improve the ability of desulfurization and dealkaliization of slag, stabilize MgO content, and improve reflow performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

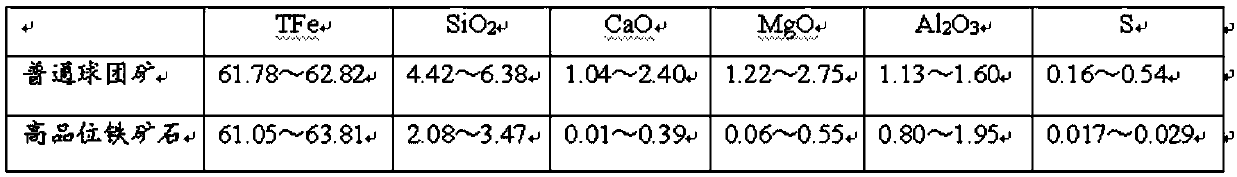

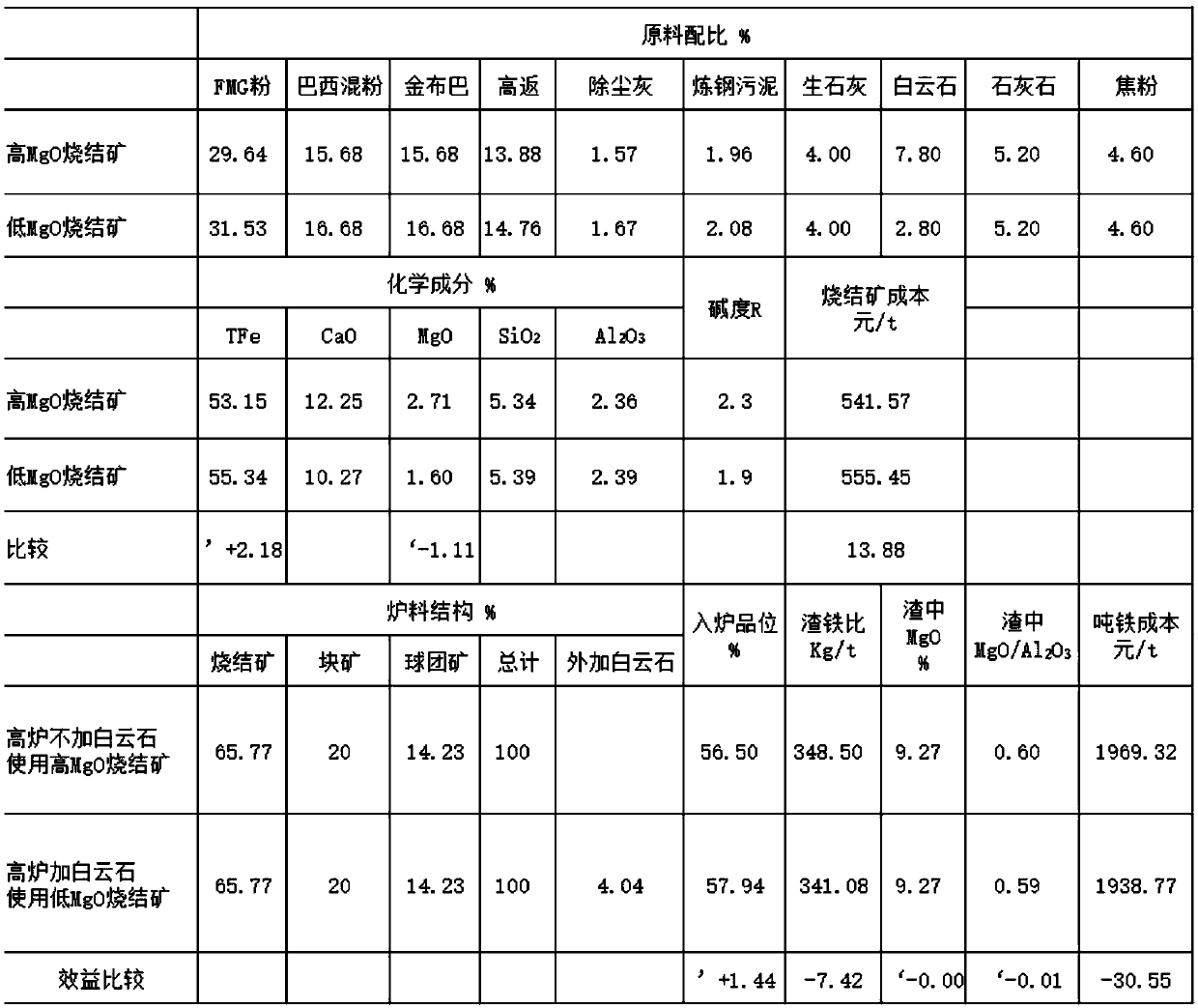

[0020] The invention provides a technical solution: a method of adjusting the burden structure ratio of blast furnace slag MgO. The blast furnace smelting charge is composed of low MgO sinter, pellet ore, lump ore and dolomite, wherein the burden structure ratio (%) It is: the low MgO sintered ore is 65.77, the lump ore is 20, the pellet ore is 14.23, and 4% of the 10-40mm dolomite block is added as a supplement, the raw material of the low MgO sintered ore Proportions (%) include: FMG powder 31.53, Brazil mixed powder 16.68, Jinbuba 16.68, high return 14.76, dedusting ash 1.67, steelmaking sludge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com