A long afterglow material and its preparation method and application

A technology of long afterglow materials and carbon dots, applied in luminescent materials, data processing applications, chemical instruments and methods, etc., can solve problems such as difficult to obtain RTP materials, and achieve the effects of low cost, wide application range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

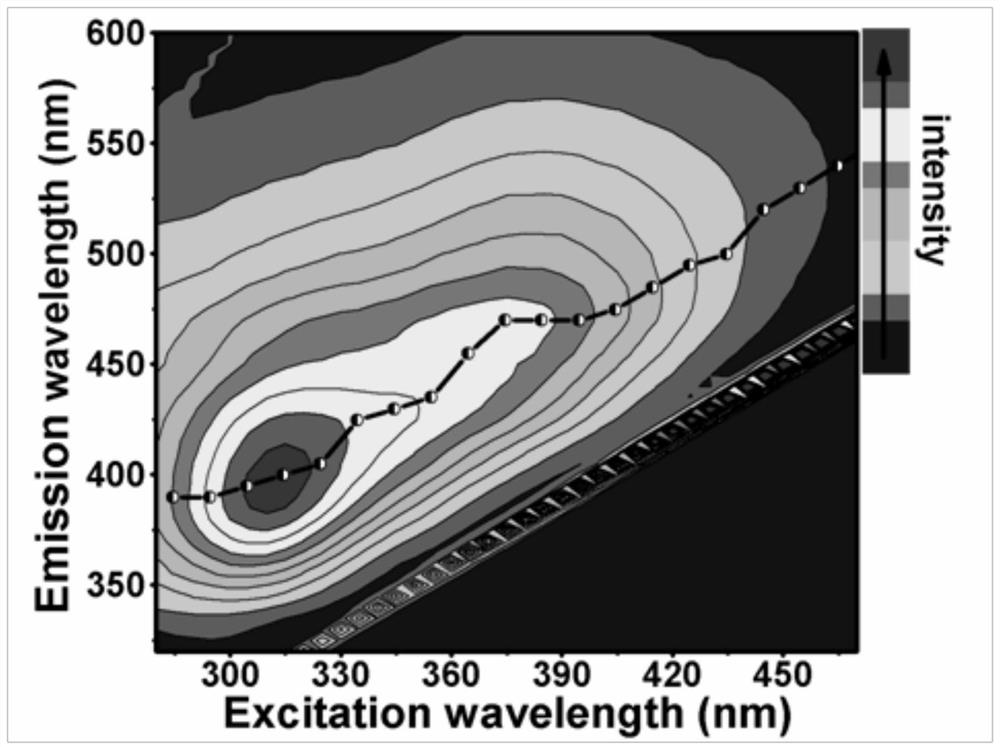

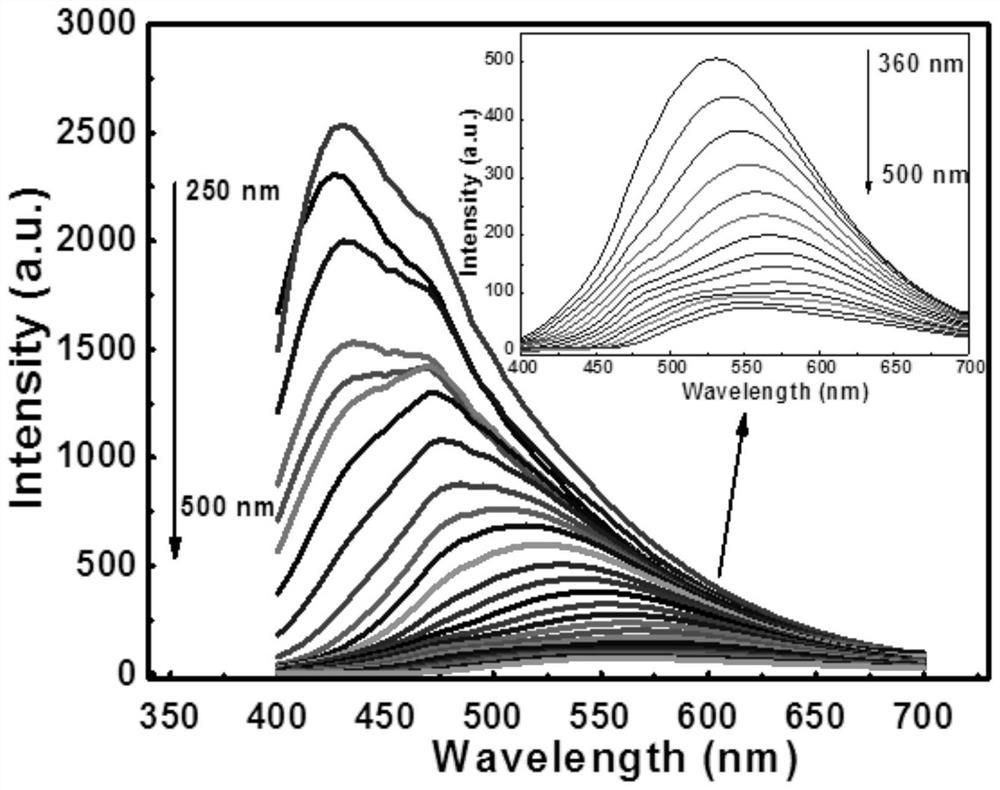

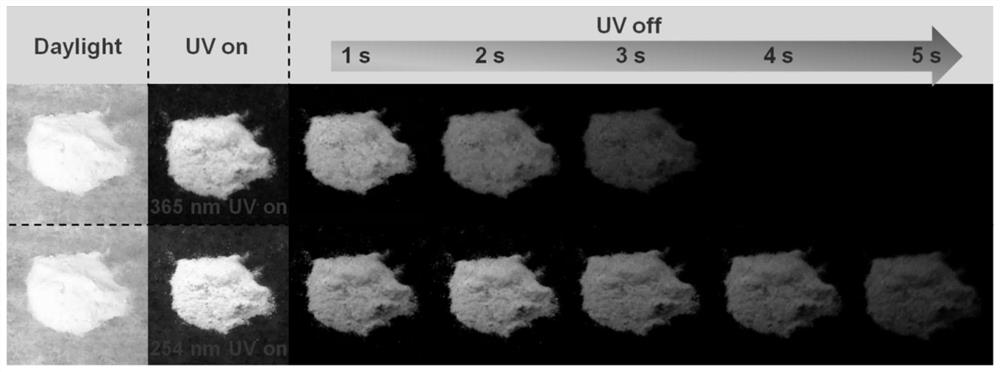

Method used

Image

Examples

Embodiment 1

[0055] The preparation of metal-free RTP material CDs / BA composite material, the specific steps are as follows:

[0056] (1) Preparation of CDs: the preparation of a-CDs uses an organic acid system, specifically, the raw material is anhydrous citric acid, and the synthesis method is a solvothermal method. Roughly divided into the following two steps: First, weigh 1 g of anhydrous citric acid and dissolve it in 20 mL of distilled water, and transfer the obtained solution into a large beaker. Next, heat the large beaker at 180°C in a heating mantle until the solution turns brown. After it cools down to room temperature naturally, take out the sample for separation and purification, and finally obtain the desired a-CDs without heteroatoms, and store them in the refrigerator for later use. .

[0057] (2) Preparation of a-CDs / BA composite material: First, weigh 3 g of BA and transfer it to a beaker, dissolve it with 40 mL of deionized water, then add 1 mL of a-CDs with a concentra...

Embodiment 2

[0072] The preparation of the metal-free RTP material b-CDs / BA composite material, the specific steps are as follows:

[0073] (1) Preparation of CDs: The preparation of CDs uses an organic compound system. Specifically, polyvinyl alcohol is used as a raw material to synthesize CDs by a one-step hydrothermal method. water, and transfer the resulting solution to a reaction kettle. Secondly, put the reaction kettle in an oven at 200°C for 10 h, and wait for it to cool down to room temperature naturally. The reacted solution was separated and purified, and finally the desired b-CDs without heteroatoms were obtained and stored in a refrigerator for future use.

[0074] (2) Preparation of b-CDs / BA composite material: First, weigh 3 g of BA and transfer it to a beaker, dissolve it with 40 mL of deionized water, then add 1 mL of b-CDs with a concentration of 0.01 g / mL, and stir with a magnetic force Stir for 30 minutes to allow it to mix well. Wrap the beaker with foil to prevent ...

Embodiment 3

[0078] The preparation of metal-free RTP material c-CDs / BA composite material, the specific steps are as follows:

[0079] (1) Preparation of CDs: CDs were prepared using an organic sugar compound system. Specifically, glucose was used as a raw material to synthesize CDs by microwave method. The resulting solution was transferred to a glass vial. Secondly, put the glass bottle in a microwave oven at a certain power (for example, 800W) to react for 10 minutes, and wait for the glass bottle to cool down to room temperature naturally. The reacted solution was separated and purified, and finally the desired c-CDs without heteroatoms were obtained and stored in a refrigerator for future use.

[0080] (2) Preparation of c-CDs / BA composite material: First, weigh 3 g of BA and transfer it into a beaker, dissolve it with 40 mL of deionized water, then add 1 mL of c-CDs with a concentration of 0.01 g / mL, and stir with a magnetic force Stir for 30 minutes to allow it to mix well. Wrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com