Die for RFI integral forming of J-shaped composite material stiffened wall plate

A technology of reinforced wall panel and integral molding, which is applied in the field of RFI integral molding of composite material "J" type reinforced wall panel, can solve problems such as affecting the molding quality, affecting the internal quality of parts, and inappropriate matching, and reducing the Difficulty in mold processing, increased difficulty in mold assembly, and improved reliability in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

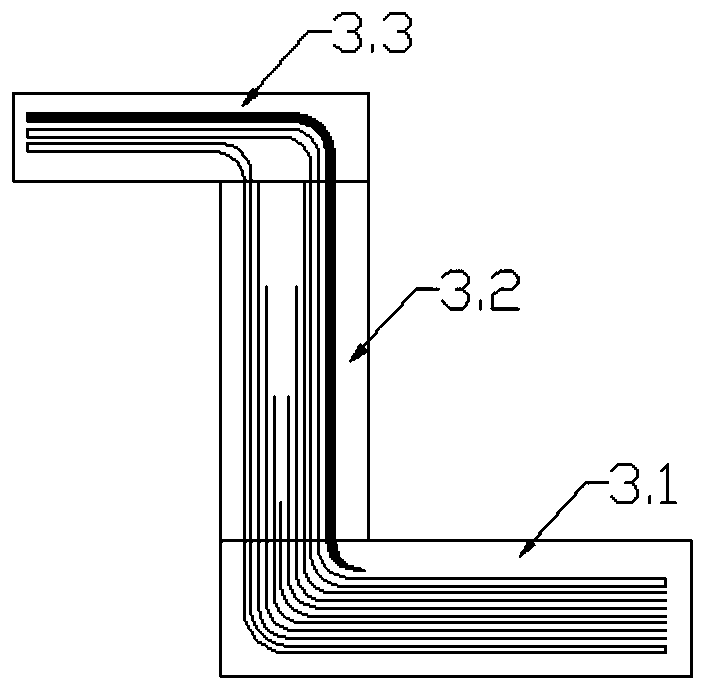

[0052] Example 1: A composite wall panel is designed as a reinforced panel with six "J"-shaped stringers, with a size of 1.2m*0.9m and a flange thickness of 1.1mm. The lower flange of the truss and the skin adopt stitching technology and are integrally formed through the RFI process. The inside of the girder is connected to the corner box, and the two ends of the girder are assembled with the beam. The coordination relationship is complicated, and high requirements are put forward for the profile and position of the girder. The requirement of resin transfer in the RFI process of the reinforced wall panel cannot be realized by using the conventional solid male mold. On the other hand, because the "J" type reinforced mold is slender and weak in rigidity, it is difficult to process and prone to processing deformation. The problem of processing deformation will lead to improper cooperation between the inner and outer molds, resulting in excessive thickness and surface quality prob...

Embodiment 2

[0070] Example 2: A composite wall panel is designed as a reinforced panel with 6 "J"-shaped stringers, and there are 4 fractures in the middle to divide each stringer into 5 sections, with a total length of 4.6m and a downward convex The thickness of the edge is 3.2mm, and the lower flange of the long truss and the skin adopt the stitching technology, and are integrally formed by the RFI process. The inside of the girder is matched with multiple corner boxes, and the two ends of the girder and the fracture area are assembled with the beam. The coordination relationship is complicated, and high requirements are put forward for the profile and position of the girder. The "J" type composite material reinforced wall The mold for integral forming of panel RFI adopts this scheme, which meets the requirements of RFI process resin transfer and the requirements of the inner and outer profiles of the panel, the position of the long truss, and the thickness accuracy.

[0071] Reinforced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com