Tool clamp for welding and manufacturing aluminum alloy trapezoid steel structures

A tooling fixture and steel structure technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding position deviation, unstable butt joint, poor welding effect, etc., and achieve the improvement of welding operation efficiency and convenience The effect of welding operation, easy handling and placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

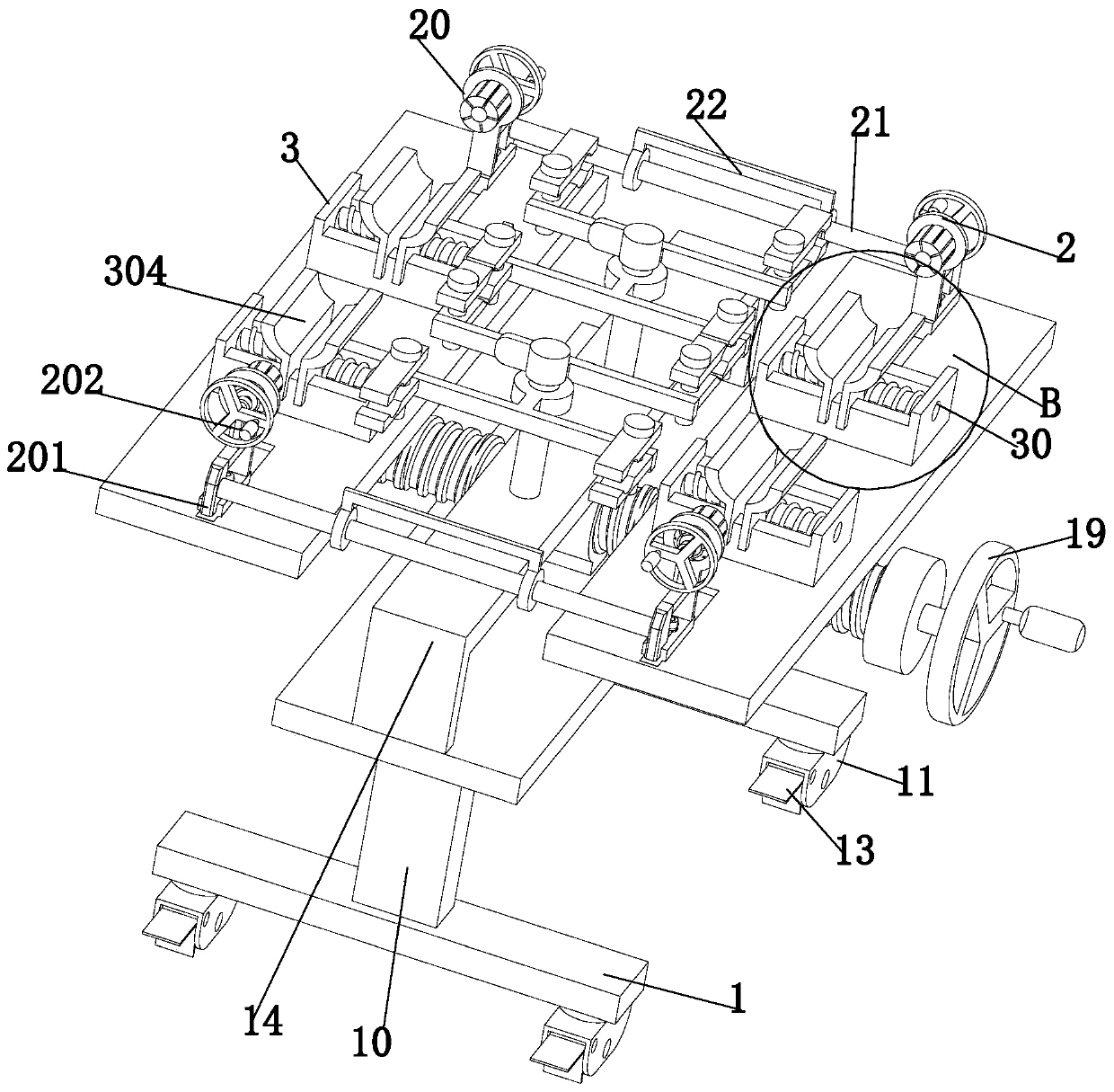

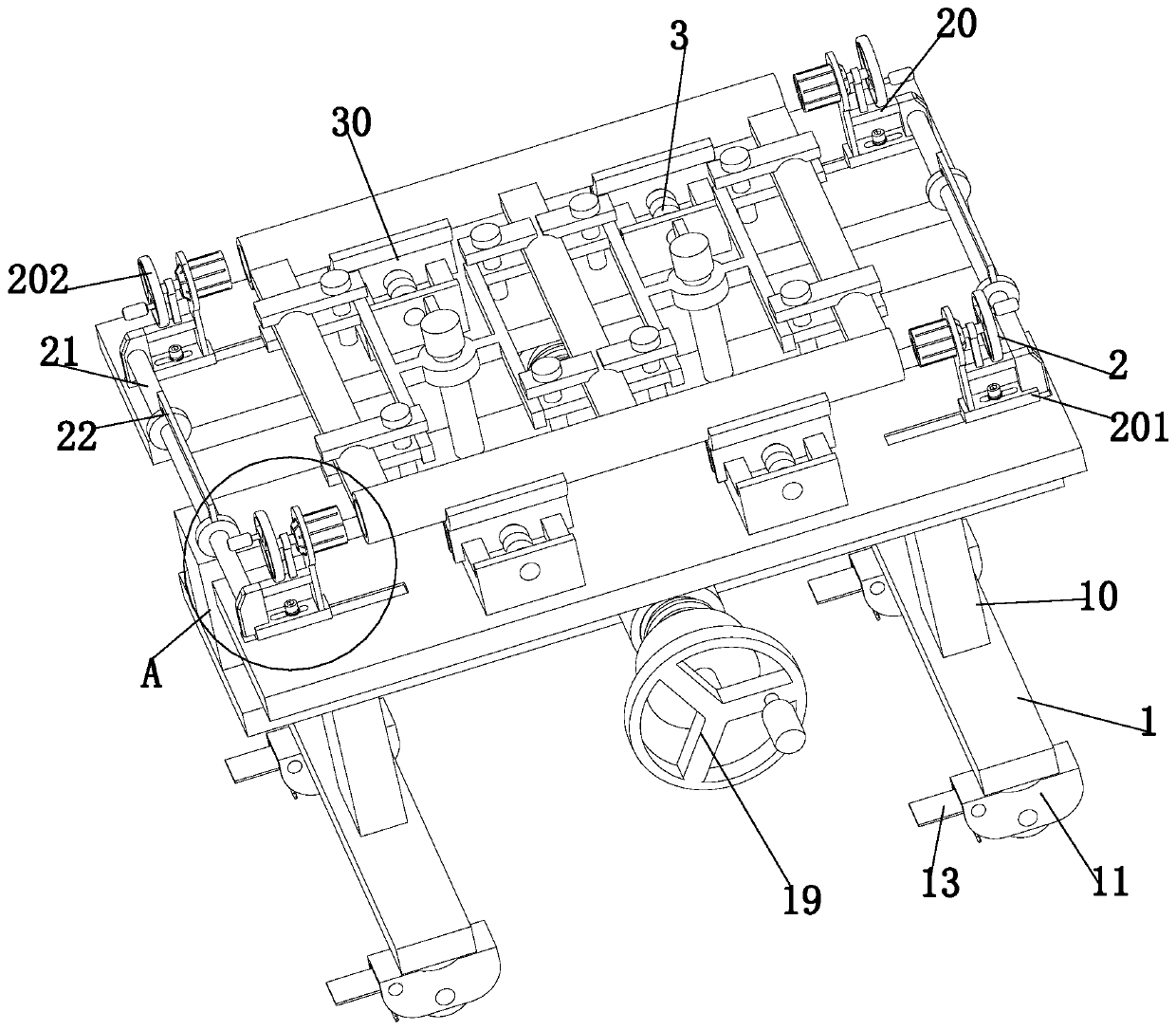

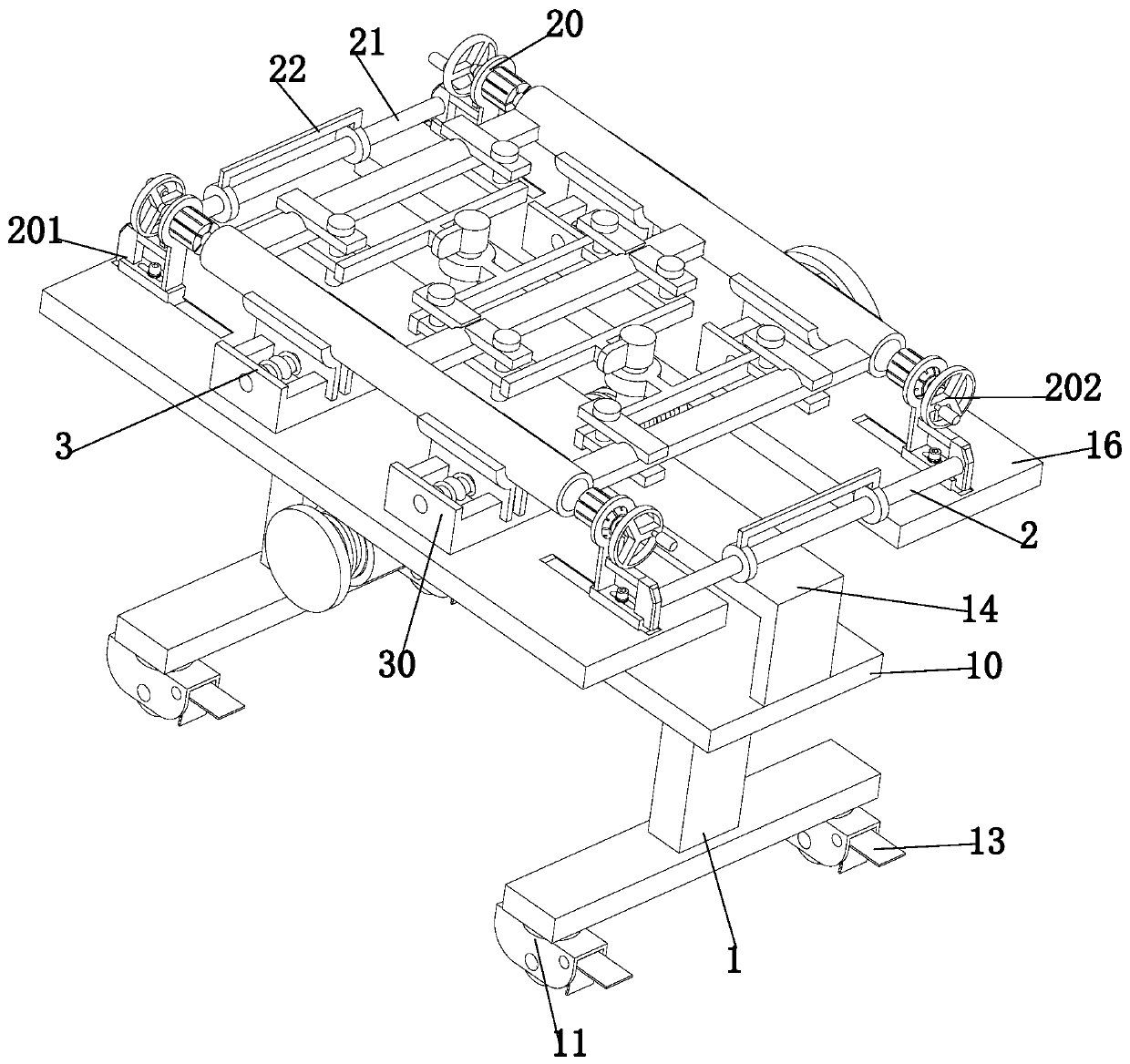

[0026] Such as Figure 1 to Figure 7 As shown, an aluminum alloy trapezoidal steel structure welding and manufacturing tooling fixture includes a bottom plate mechanism 1, an actuator 2 and a fastening mechanism 3. The bottom plate mechanism 1 is symmetrically installed with the actuator 2 and the fastening mechanism 3 Installed on the bottom plate mechanism 1, and the fastening mechanism 3 is located in the middle of the two actuators 2, where:

[0027] The bottom plate mechanism 1 includes a bottom bracket 10, a pulley frame 11, a rolling wheel 12, a fixed brake pad 13, a bow frame 14, a fixed rod sleeve 15, an upper support plate 16, a left spiral wire lever 17, a right spiral wire lever 18. Rocker arm hand wheel 19 and sliding sleeve 19A; the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com