Plant factory vertical-horizontal tube ventilation method and device

A ventilation device and horizontal pipe technology, applied in the field of plant factory vertical-horizontal pipe ventilation method and its device, to achieve the effect of small vertical pipe diameter, small area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 The present invention is a plant factory vertical-horizontal tube ventilation device composed of a plurality of double-standpipe ladder-shaped ventilation units

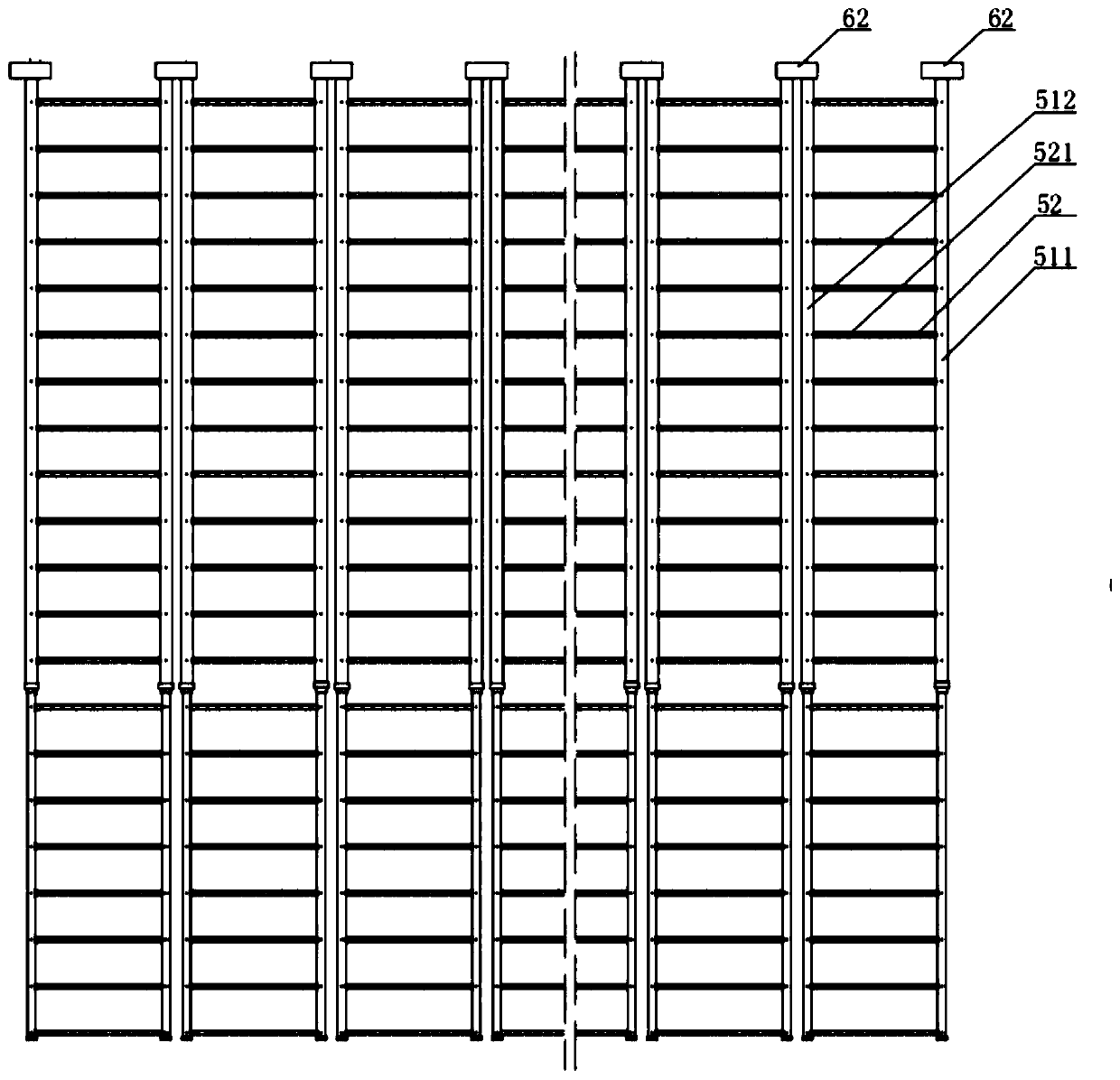

[0050] The ventilation principle diagram of the plant factory vertical-horizontal tube ventilation device installed with multiple double-standpipe ladder-shaped ventilation units in this implementation is shown in the top view ventilation principle diagram. figure 1 , see 2 for a schematic diagram of the front elevation structure of the plant factory vertical-horizontal tube ventilation device composed of multiple double-standpipe ladder-shaped ventilation units.

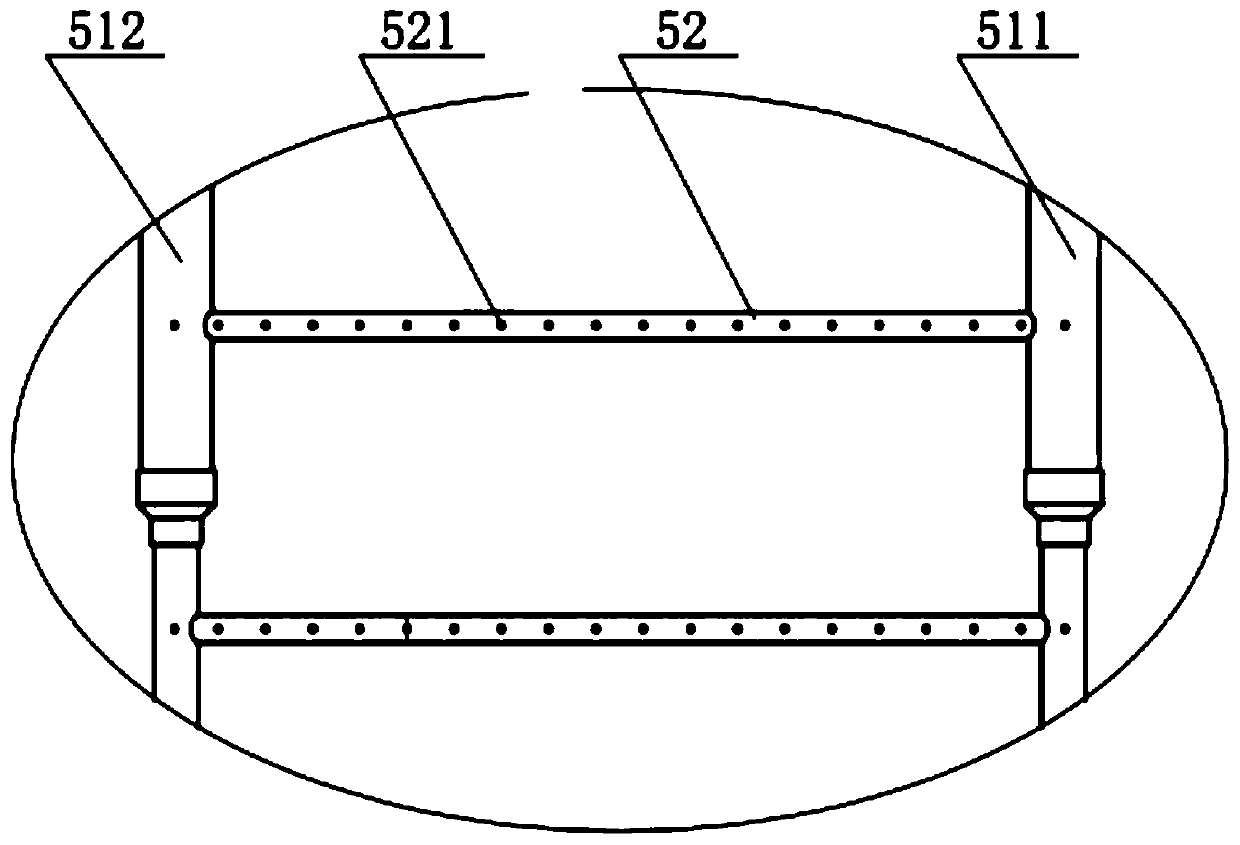

[0051] In this embodiment, the plant factory vertical-horizontal tube ventilation device composed of a plurality of double-standpipe ladder-shaped ventilation units is processed with pvc pipe fittings, and its appearance is like a plurality of ladders. 512) and a plurality of horizontal tubes 52; an even number of standpipes are arrange...

Embodiment 2

[0058] Embodiment 2 The present invention is a plant factory vertical-horizontal tube ventilation device composed of a plurality of single vertical tube ladder-shaped ventilation units

[0059] The plant factory vertical-horizontal tube ventilation device that is installed with a plurality of single riser ladder-shaped ventilation units in this embodiment is viewed from above for the ventilation principle diagram. Figure 4 , the air inlet of the single riser ladder-shaped ventilation unit can be set at the top or at the bottom, wherein the air inlet is at the top of the single riser ladder-shaped ventilation unit of the structural diagram Figure 5 , showing the facade structure of the plant factory vertical-horizontal tube ventilation device (the air inlet is on the top) composed of multiple single-stand pipe ladder-shaped ventilation units Figure 6 , the structural diagram of a single riser ladder-shaped ventilation unit (the air inlet is at the bottom and equipped with a ...

Embodiment 3

[0066] Embodiment 3 uses plant factory vertical-horizontal pipe ventilation device of the present invention in conjunction with bellows

[0067] For the plant factory vertical-horizontal tube ventilation device used, refer to the plant factory vertical-horizontal tube ventilation device composed of a plurality of double-stander ladder-shaped ventilation units in Example 1. This embodiment is used in combination with a bellows, and its ventilation principle diagram is shown in Figure 9 , wherein 1 is a cultivation frame, 2 is a cultivation bed, 3 is a light source, 4 is between plant cultivation layers, 511 is a right riser, 512 is a left riser, 52 is a horizontal pipe, 62 is an air inlet, and the air inlet 62 is in the vertical The top of the pipe, the bottom end of the standpipe is closed, and the air inlet 62 of the plant factory ladder-shaped air duct ventilator is connected to the air inlet bellows 73, and the air inlet is also equipped with an air supply regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com