Workpiece annealing device

A technology for annealing equipment and workpieces, applied in heat treatment equipment, lighting and heating equipment, furnace components, etc., can solve problems such as lack of heating capacity, unstable temperature uniformity, and blocked pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

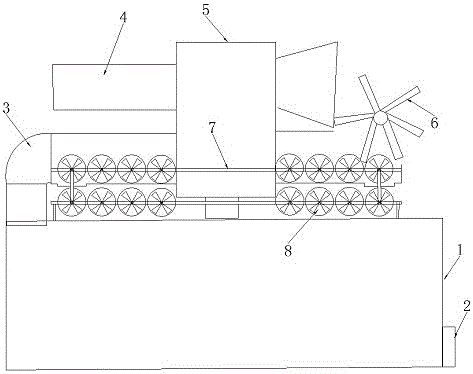

[0016] The reference signs in the drawings of the description include: furnace body 1 , air inlet 2 , smoke outlet pipe 3 , preheating pipe 4 , heat exchanger 5 , wind wheel 6 , slide rod 7 , and roller 8 .

[0017] The embodiment is basically as figure 1 Shown:

[0018] The workpiece annealing equipment of this embodiment includes a furnace body 1, a smoke outlet pipe 3 is provided on one side of the top of the furnace body 1, a heat exchanger 5 is provided in the center of the top of the furnace body 1, and the smoke outlet pipe 3 passes through the lower part of the heat exchanger 5 , The upper part of the heat exchanger 5 is provided with a preheating pipe 4, and the inlet of the preheating pipe 4 is larger than the outlet of the preheating pipe 4. Two layers of sliding rods 7 are placed on the furnace body 1, and connecting rods are arranged between the two layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com