Intelligent monitoring system for operation and maintenance state of power equipment

A technology for power equipment and intelligent monitoring, applied in information technology support systems, electrical components, measuring devices, etc., can solve problems such as unbalanced deployment of distributed optical fiber nodes, inaccurate data detection, strong correlation of perceived data, etc., to reduce defects Incidence rate, improvement of work efficiency, and effect of reducing prediction error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

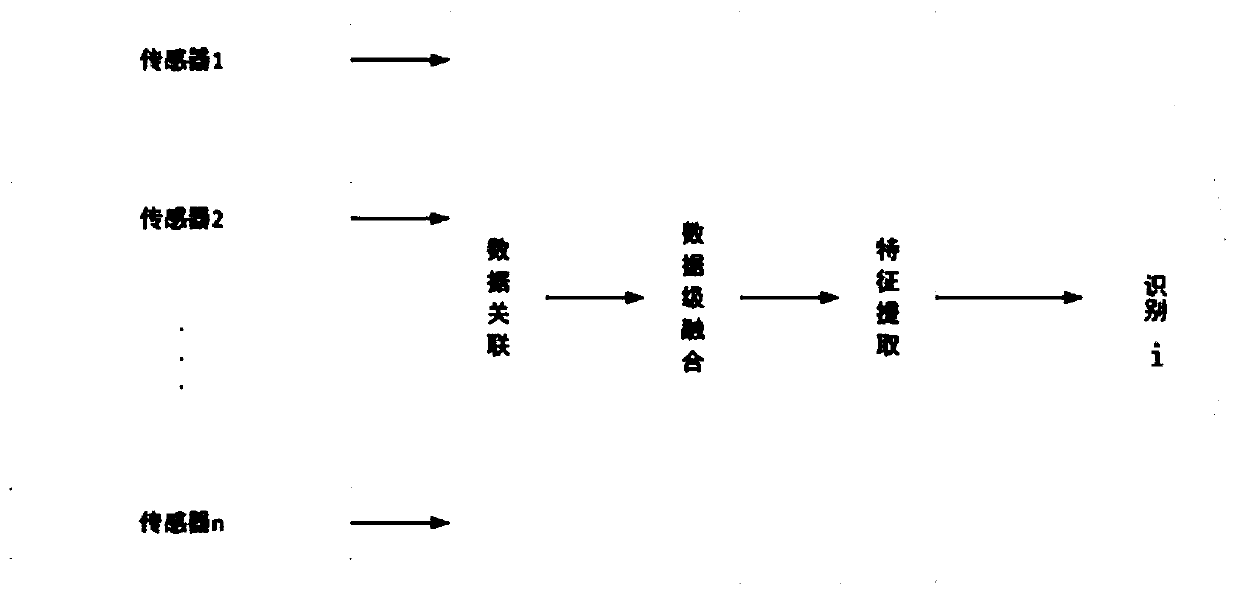

[0043] This embodiment provides an intelligent monitoring system for the operation and maintenance status of electric power equipment, including a signal sensing device, a data acquisition device, and an information calculation and diagnosis device connected in sequence. The signal sensing device includes a distributed optical fiber sensor, which is distributed and installed on the power equipment to be tested. The information computing diagnostic device stores a program for executing the following steps:

[0044] Send data read trigger signal regularly;

[0045] Based on the collected data, use the built prediction model based on the linear autoregressive method to perform prediction processing, realize data flow optimization, and obtain the final sampling data of the power equipment to be tested;

[0046] The monitoring results of the power equipment under test are obtained based on the final sampling data.

[0047] 1. Signal perception device

[0048] The distributed opti...

Embodiment 2

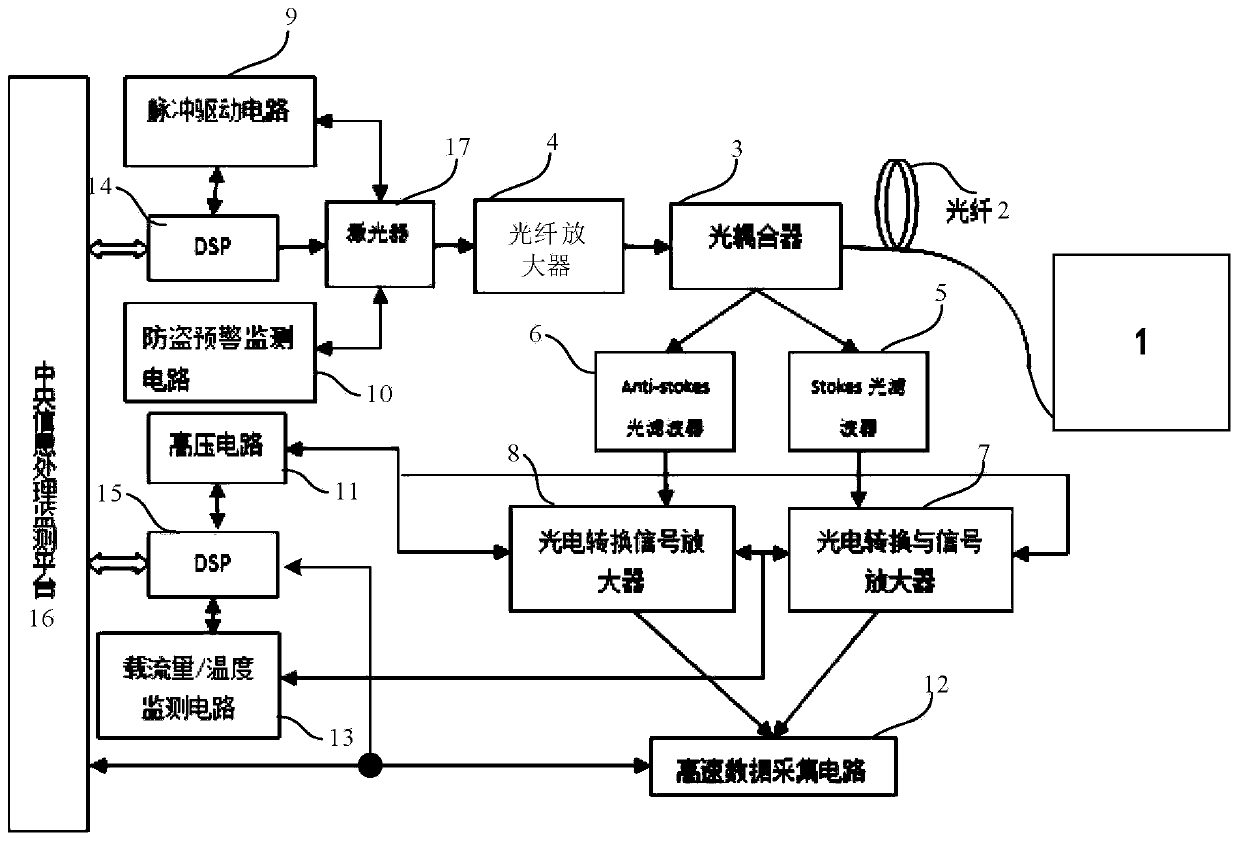

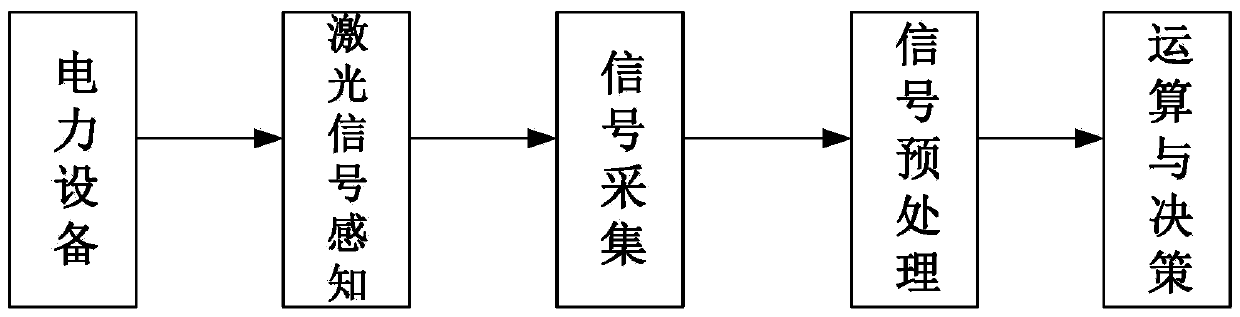

[0109] The intelligent monitoring system for power equipment operation and maintenance status provided in this embodiment is as follows: figure 1 As shown, the electric equipment 1 is monitored in real time. Power equipment mainly refers to equipment that needs to be monitored for corresponding conditions, including transformers, switch cabinets, and transmission lines in substations. The electric equipment monitored in this embodiment is a substation. The signal flow of the monitoring system is as follows figure 2 shown.

[0110] In this monitoring system, the laser signal sensing unit includes an optical fiber 2, an optical coupler 3, an optical fiber amplifier 4, an anti-stokes optical filter 5, a stokes optical filter 6, photoelectric conversion signal amplifiers 7 and 8, a laser 17, and a pulse drive circuit 9. Anti-theft early warning monitoring circuit 10 and high voltage circuit 11.

[0111] The data acquisition device is a high-speed data acquisition circuit 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com