Automatic horizontal defoaming standard metal measuring vessel

A standard metal gauge and level technology, applied in the direction of instruments, measuring devices, testing/calibration devices, etc., can solve the problems of foam occupying the gauge volume, inaccurate oil measurement, errors, etc., to reduce weight, reduce manpower, Easy to move and light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

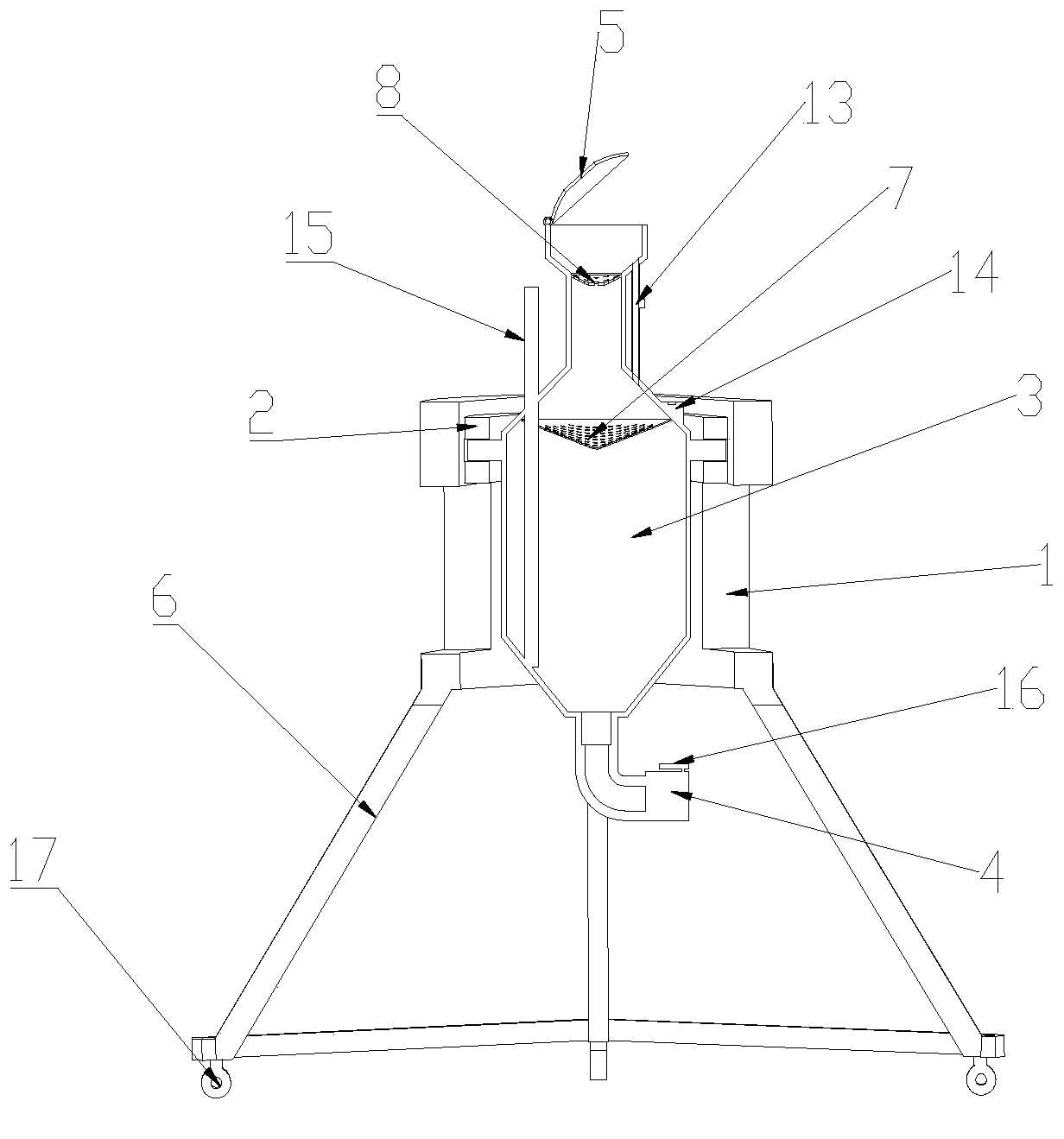

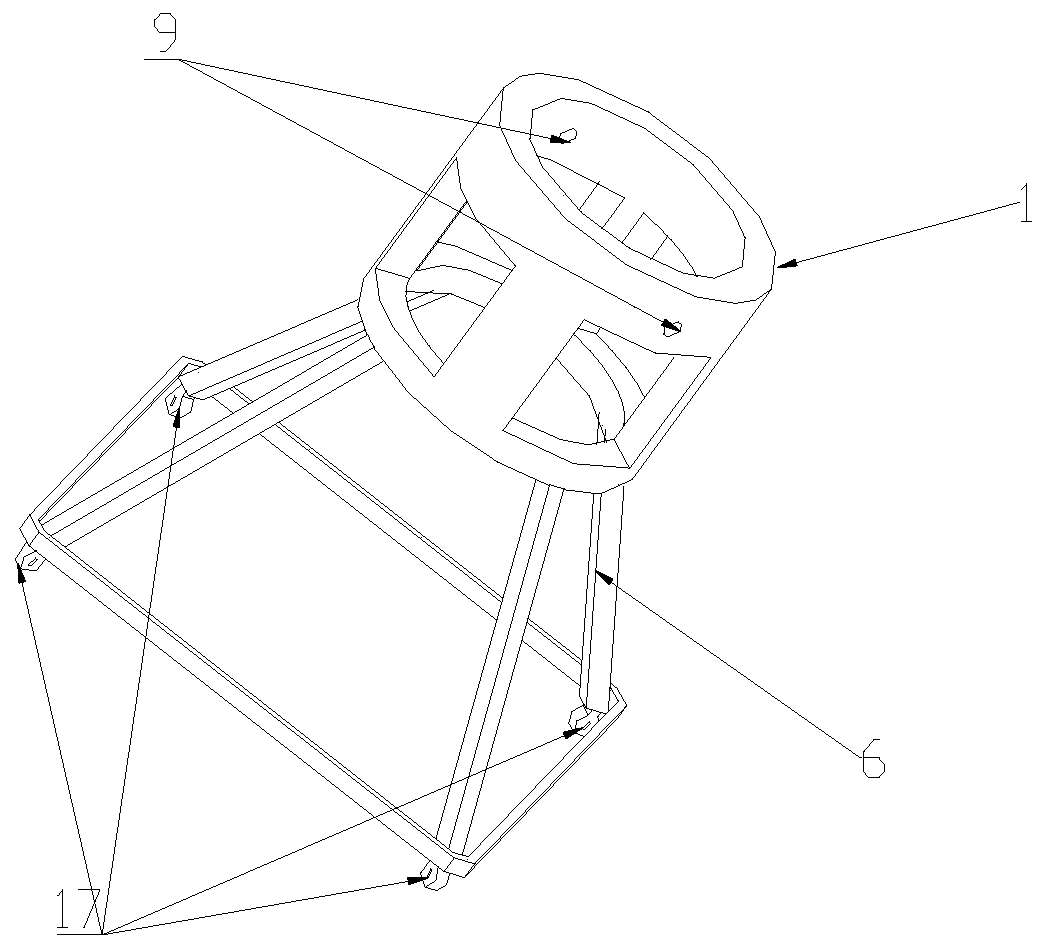

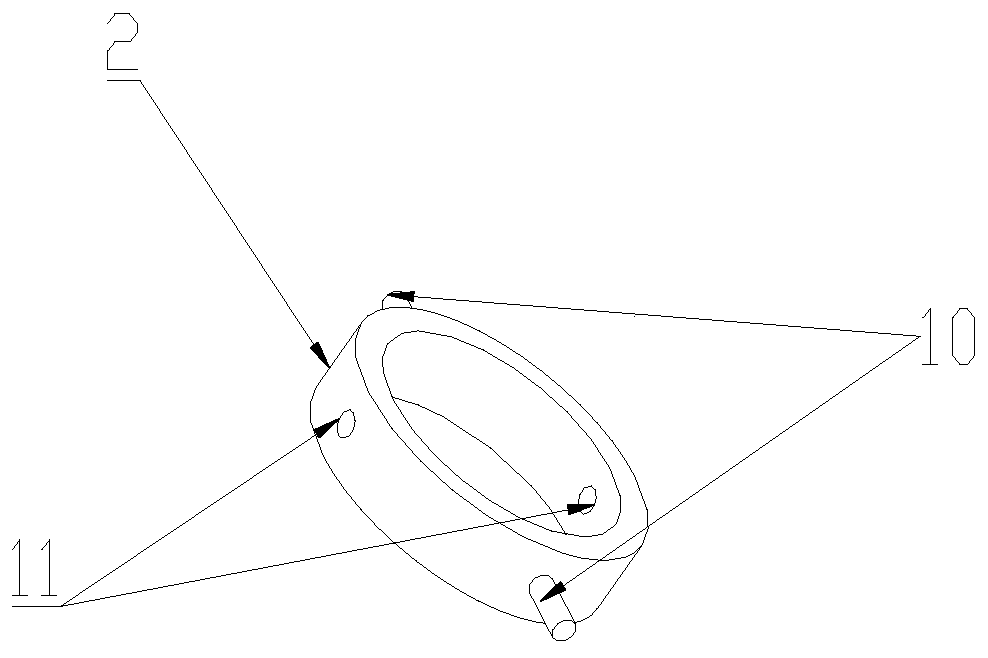

[0036] Example: see Figure 1~6, the automatic horizontal defoaming standard metal gauge, including the gauge support seat 1, the gauge support base 1 is a hollow cylinder and the outer wall is hollowed out, which can reduce the entire automatic horizontal defoaming to the greatest extent while ensuring the support function. The weight of the standard metal gauge is easy to move and carry. There is a swivel frame 2 inside the top of the gauge support base 1. The swivel frame 2 is in the shape of a ring and is a connecting piece between the gauge support base 1 and the gauge 3. , the swivel frame 2 is placed in the meter support seat 1, and can freely rotate 360° in the meter support seat 1 with the cross-section of the swivel frame 2 as the diameter. Structure: Meter 3 is installed inside the upper part of the rotating frame 2, and the meter 3 is a cylindrical structure with the upper part closed, which can contain oil medium and is a direct part for measuring the volume of oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com