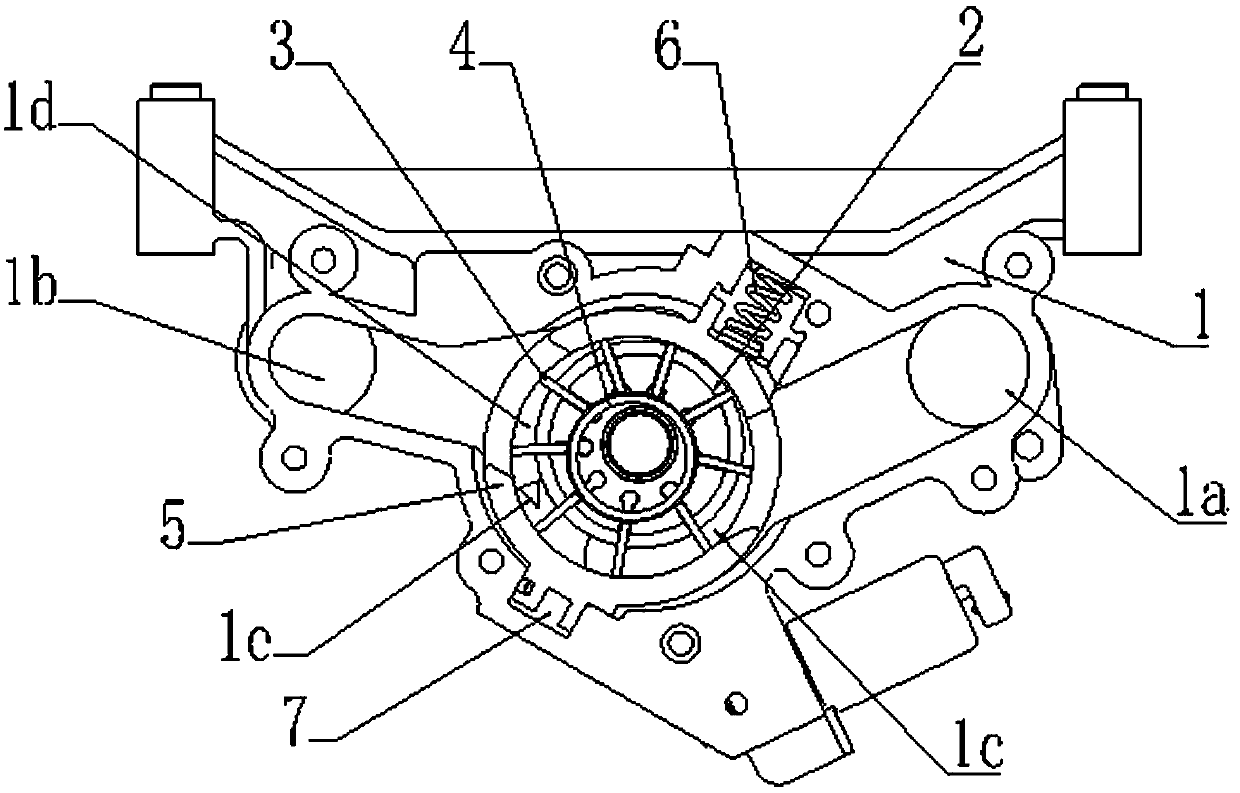

Commercial vehicle blade type variable pump

A vane type, variable displacement pump technology, applied in the direction of lubrication pumps, vehicle components, engine components, etc., can solve the problems of reducing the reliability of oil pump operation, large load, large flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

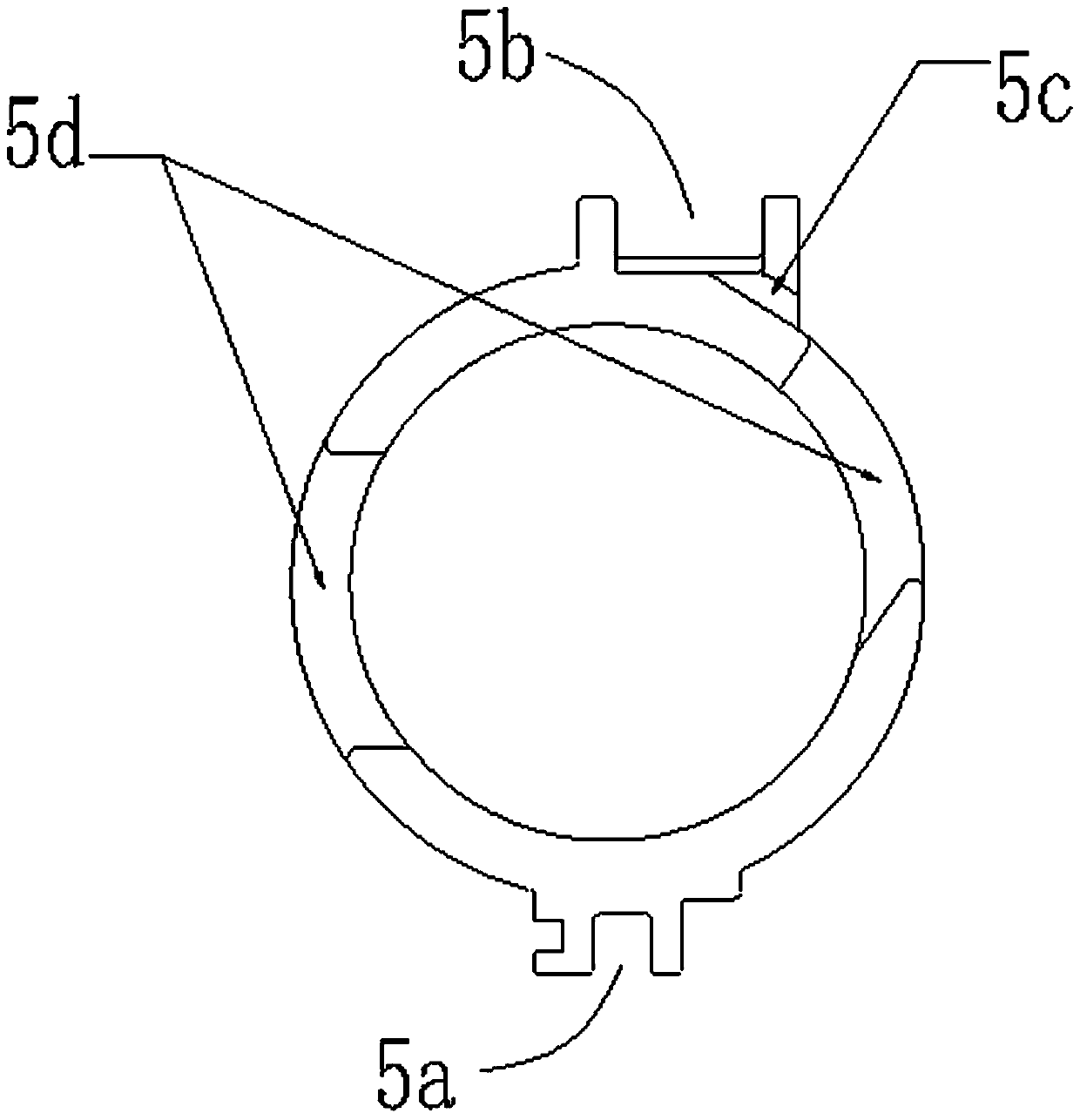

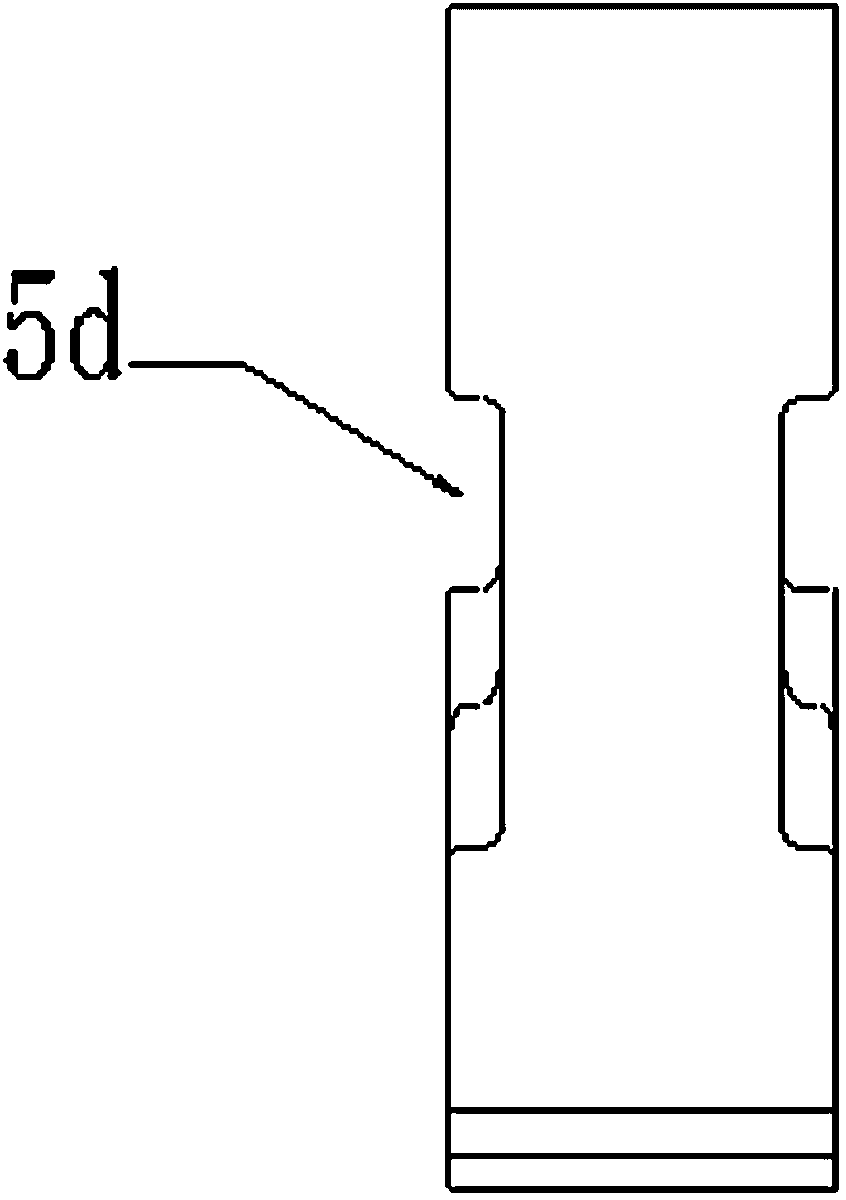

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and the drawings, and the content mentioned in the embodiments does not limit the present invention.

[0020] In the description of the present invention, it should be understood that the terms "first" and "second" are only used for description purposes, and cannot be understood as indicating or implying relative importance or implicitly indicating the number of indicated technical features. In the description of the present invention, "plurality" means two or more than two, unless specifically defined otherwise. In the description of the present invention, it should be noted that, unless otherwise specified and limited, the terms "installed", "connected", and "connected" should be understood in a broad sense. For example, they can be mechanically connected or electrically connected, or two The internal communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com