Swing type solar panel driving mechanism

A technology for solar panels and driving mechanisms, applied in electromechanical devices, mechanical equipment, electric components, etc., can solve the problems of complex conductive ring structure, affecting the performance of the whole star, low reliability, etc., and achieve high output torque and small backlash. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with embodiment.

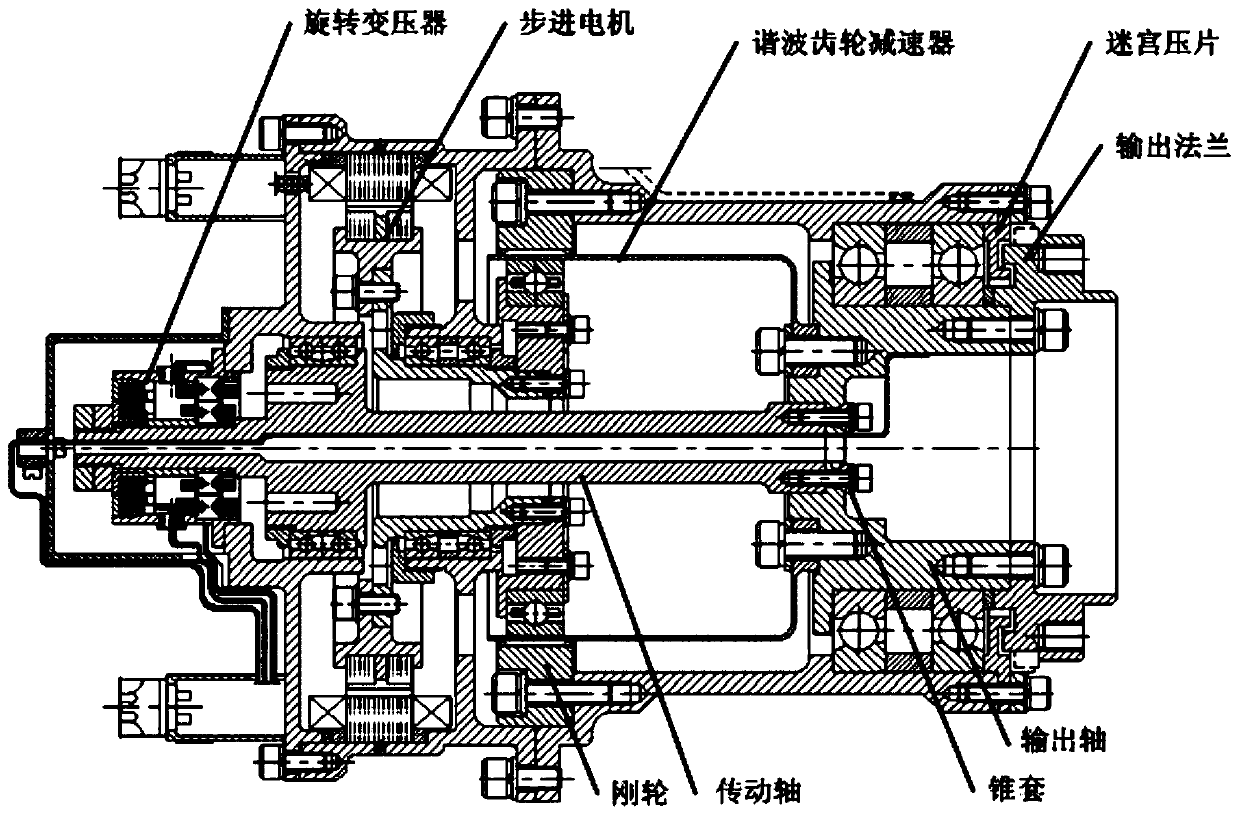

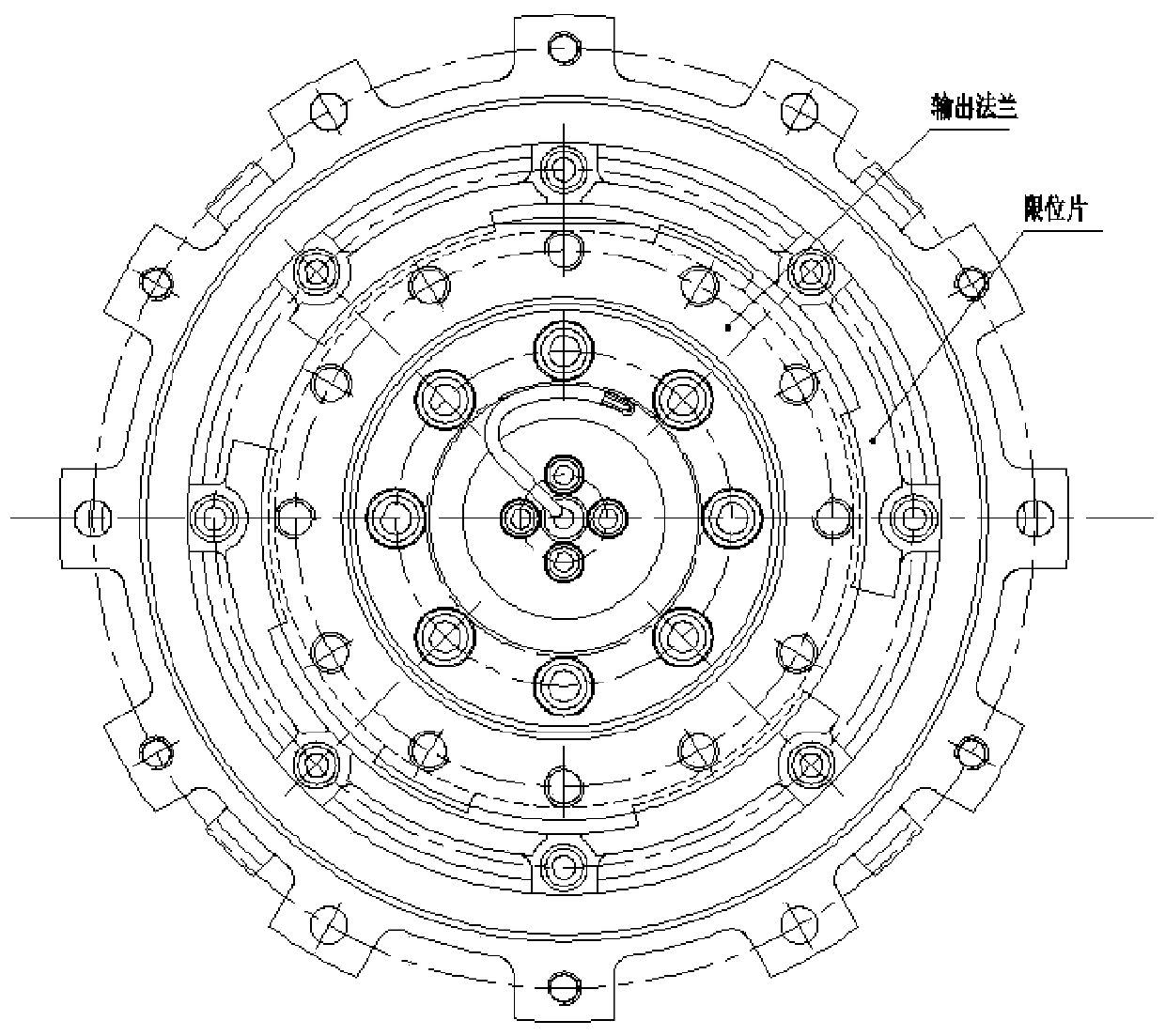

[0022] Such as figure 1 As shown, the present invention provides a swing type solar panel drive mechanism, which drive mechanism includes a rotary transformer, a stepper motor, a harmonic gear, an output shaft, a housing, a torsion cable; the fixing of the stepper motor and the harmonic gear partially mounted on the housing, where:

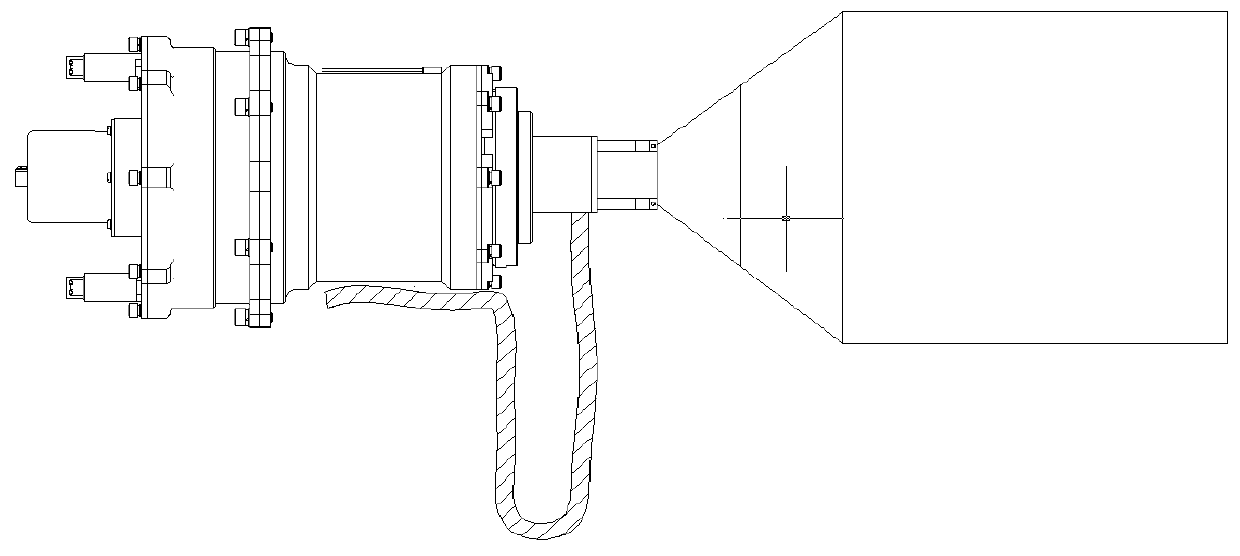

[0023] The stepper motor is connected to the harmonic gear, which is used to decelerate the speed of the stepper motor and transmit the torque of the stepper motor shaft to the output shaft, which is used to connect the external solar panel to drive the solar panel to swing ; The resolver is used to measure the rotation angle of the output shaft; one end of the torsion cable is connected to the external actuator, and the other end is connected to the casing of the driving mechanism. The torsion cable is used to replace the disc ring to complete power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com