Pipe-ship connection method suitable for deep-sea mining

A technology for deep-sea mining and hard pipes, which is applied in mineral mining, special mining, earthwork drilling and mining, etc. It can solve problems such as angle deviation, cracks, and bending of hard pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

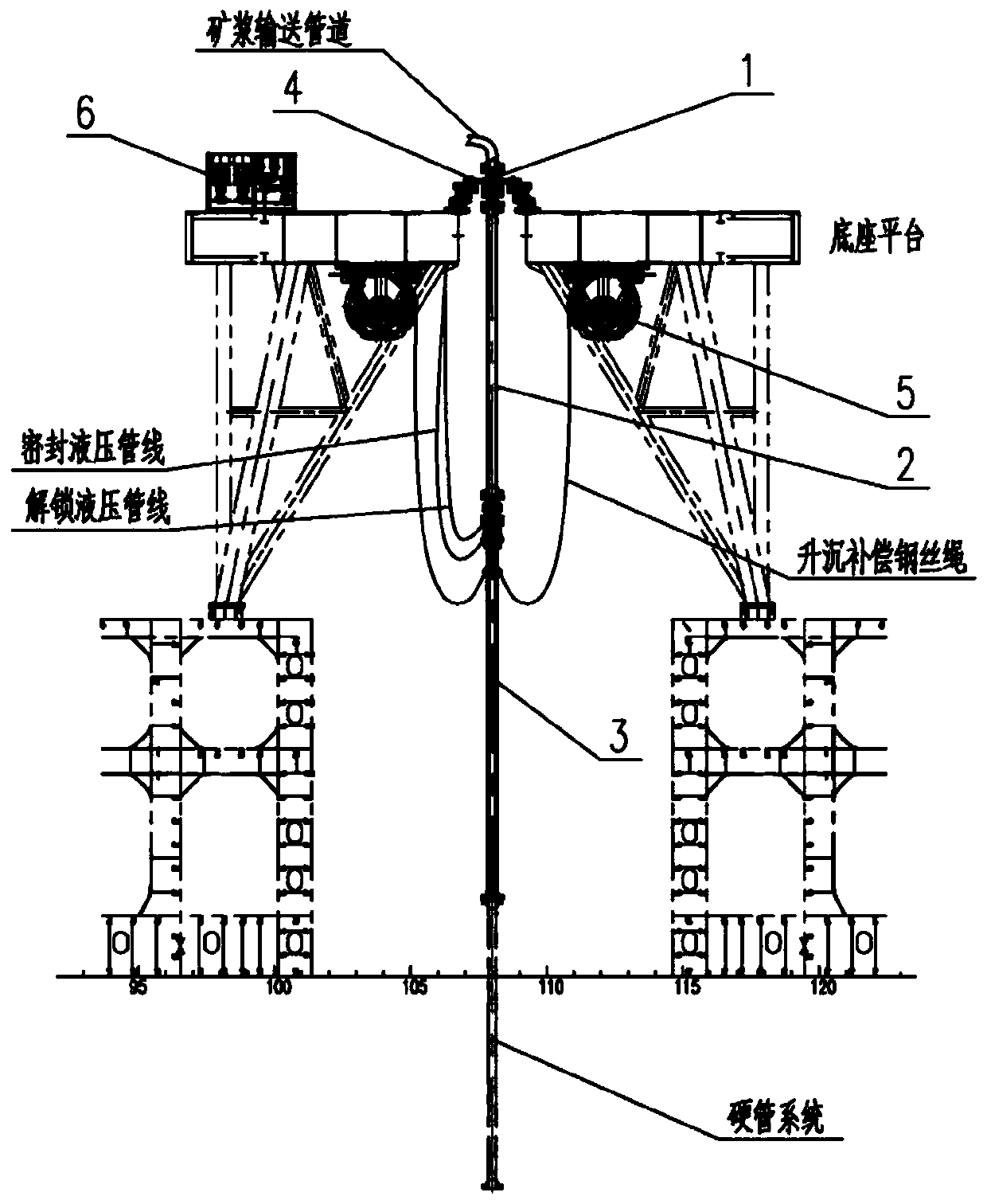

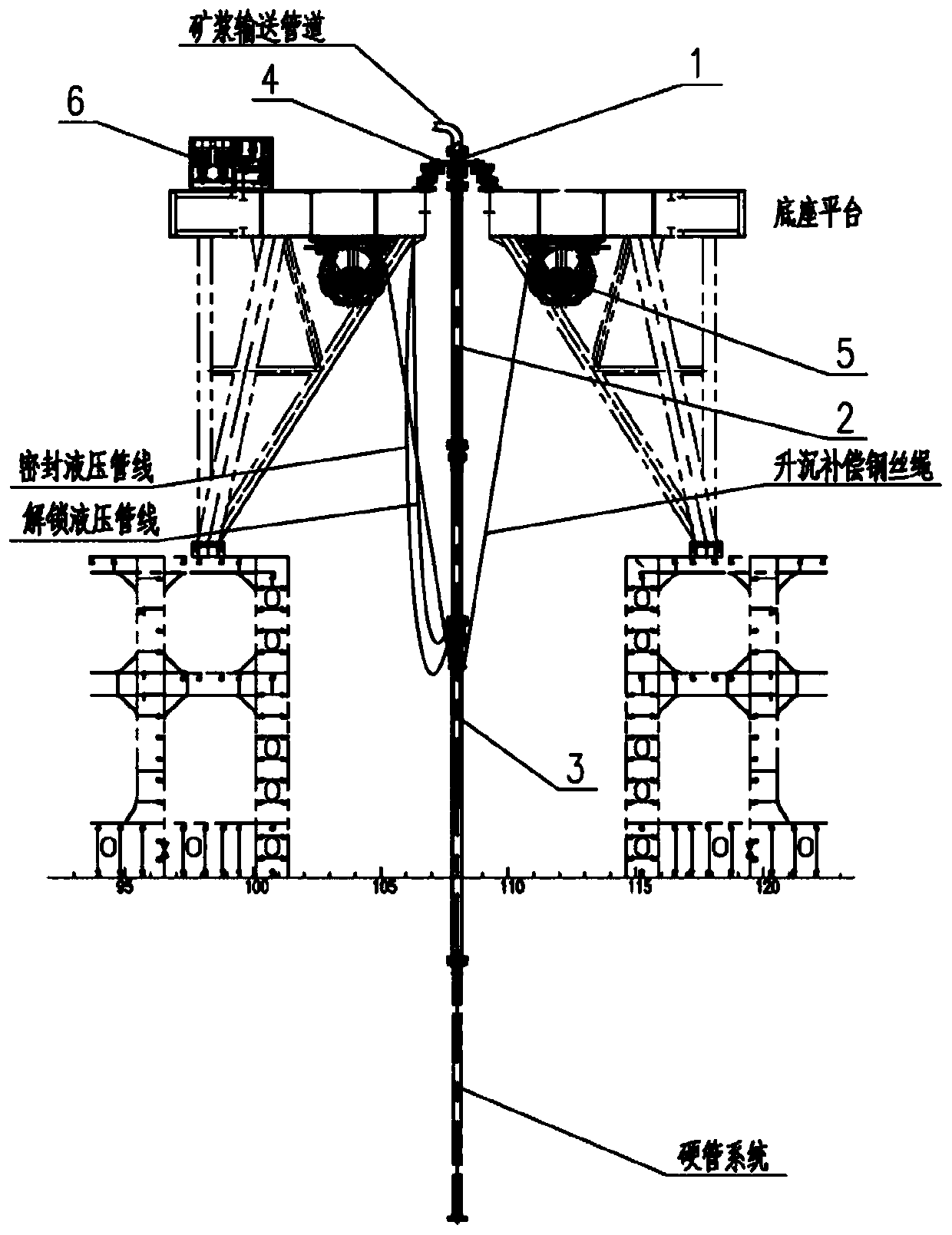

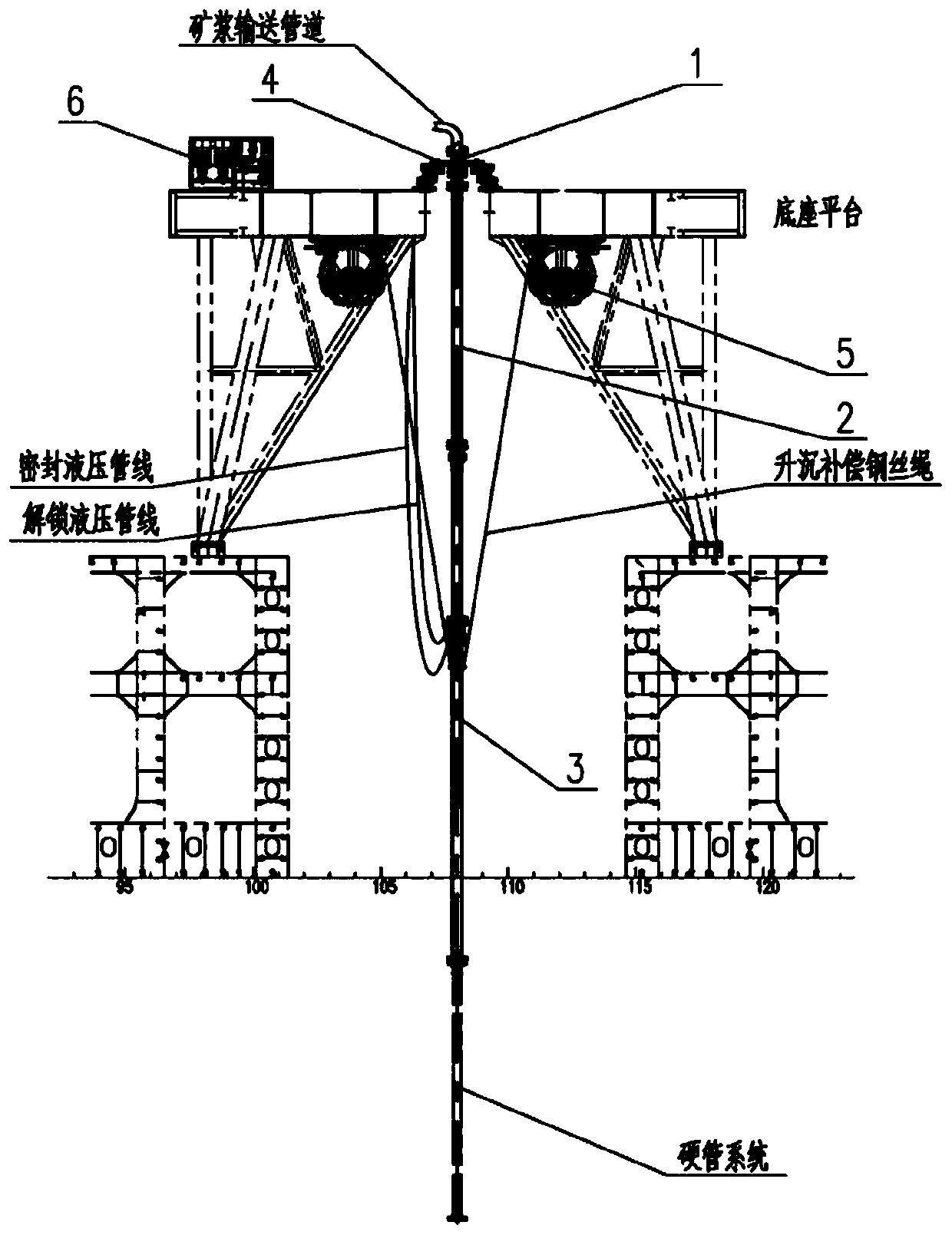

[0018] combine figure 1 , figure 2 As shown, the pipe-ship connection method suitable for deep-sea mining proposed by the present invention involves hardware and systems including ball joint 1, adjusting pup joint 2, telescopic device 3, chuck 4, heave compensation system 5, and hydraulic control system 6 , riser running tool, lifting system. Among them, the ball joint 1, the telescopic device 2 and the adjusting nipple 3 form a pipe-to-vessel connection device to compensate the heave displacement and angular displacement of the pipeline generated by waves. In the process of lowering and lifting the conveying hard pipe, the chuck 4 is used as the suspension carrier of the underwater conveying system. The heave compensation system 5 can reduce the influence of heave motion impact load on the surface support platform of heavy-duty transport systems such as hard pipes under harsh sea conditions, keep the position of the underwater relay station relative to the seabed stable, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com