Washing machine

A washing machine and clothing technology, applied in the field of washing machines, can solve the problems of easy generation of scale, adhesion of lint, overall vibration of the washing machine, influence on efficiency and safety, etc., and achieves the effects of simple structure, excellent effect and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

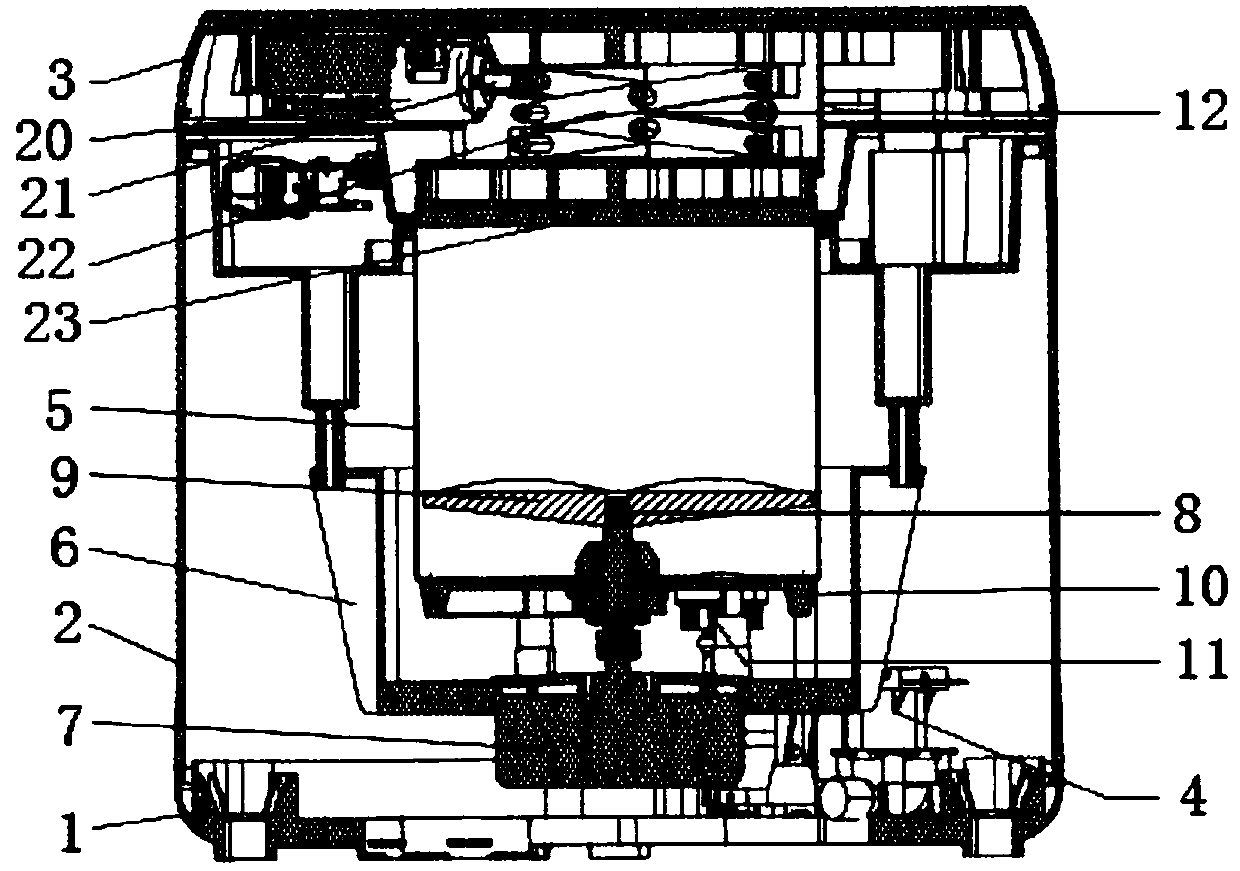

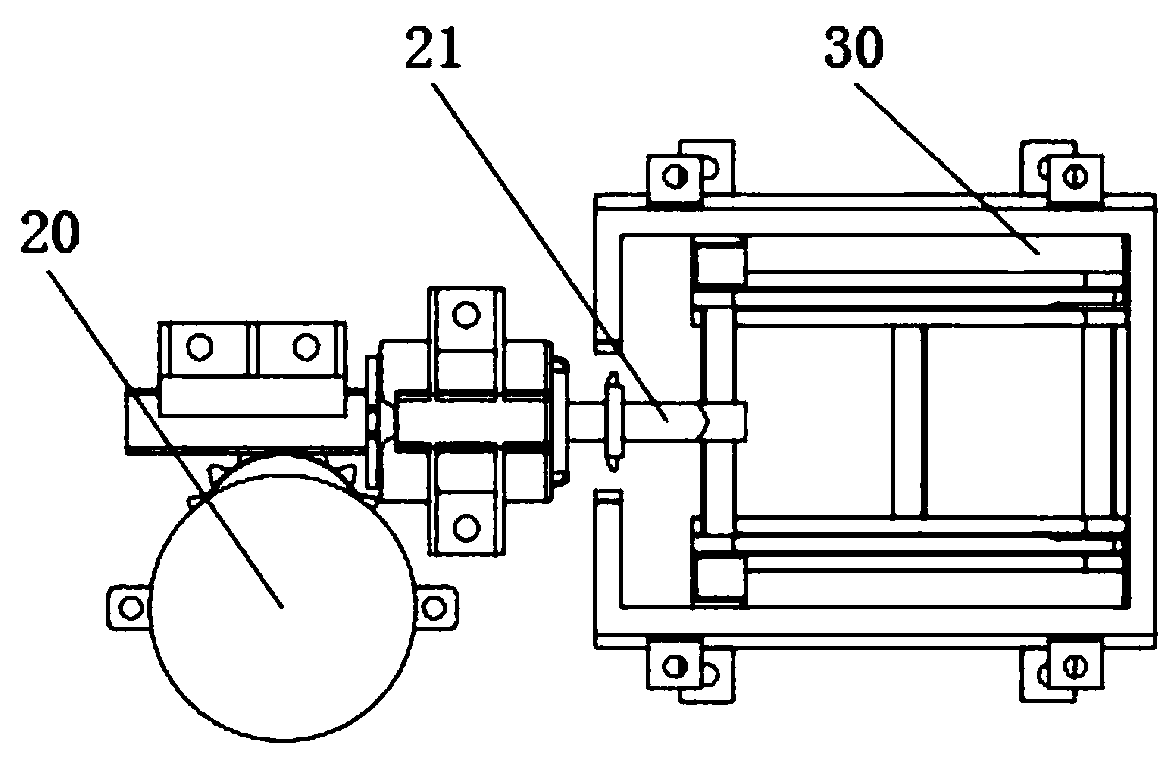

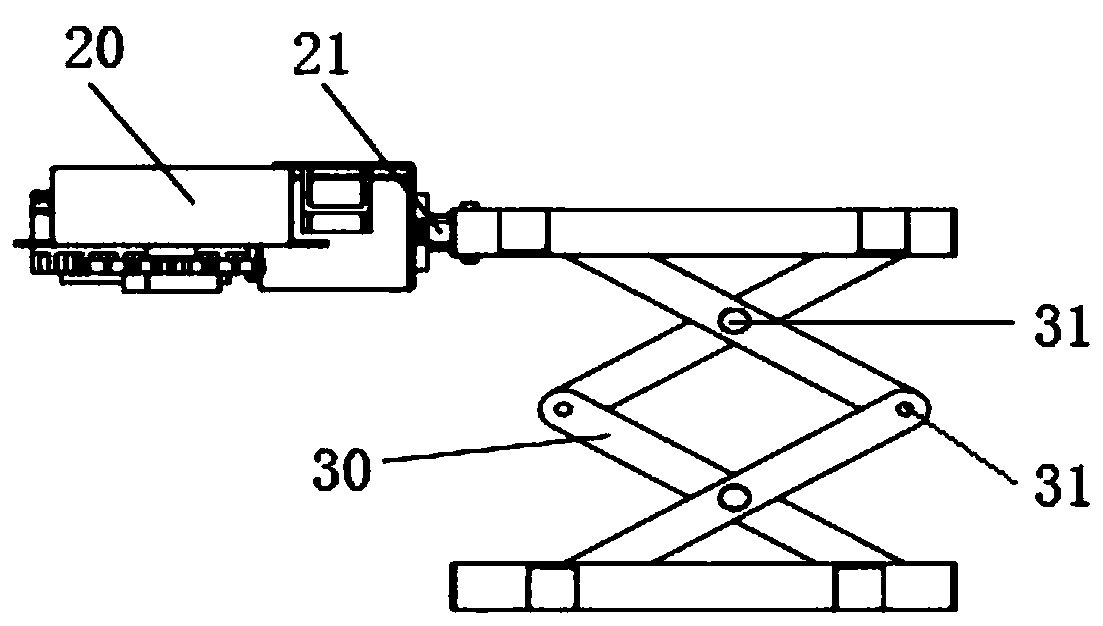

[0020] The main structure of the washing machine involved in this embodiment includes a base 1, a casing 2, an upper cover 3, a water inlet valve 4, an inner tank 5, an inner tank fixing seat 6, a washing drive module 7, a washing shaft 8, a washing pulsator 9, a heating Disc 10, drainage mechanism 11 and extrusion mechanism 12; base 1 is provided with casing 2, top of casing 2 is provided with upper cover 3, and base 1 or casing 2 or upper cover 3 is provided with water inlet valve 4, inside of casing 2 An inner container 5 is provided, and an inner container fixing seat 6 is arranged on the outside of the inner container 5, and the base 1 or the shell 2 is connected with the inner container fixing seat 6, and a washing driving module 7 is arranged between the base 1 and the inner container 5, and the washing driving module 7 is connected with the washing pulsator 9 arranged inside the inner tank 5 through the washing shaft 8, the bottom of the inner tank 5 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com