Compound, liquid crystal composition, liquid crystal display element and liquid crystal display device

A technology for liquid crystal compositions and compounds, applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problem of high manufacturing costs, achieve lower production costs, wide nematic phase temperature range, and good UV resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

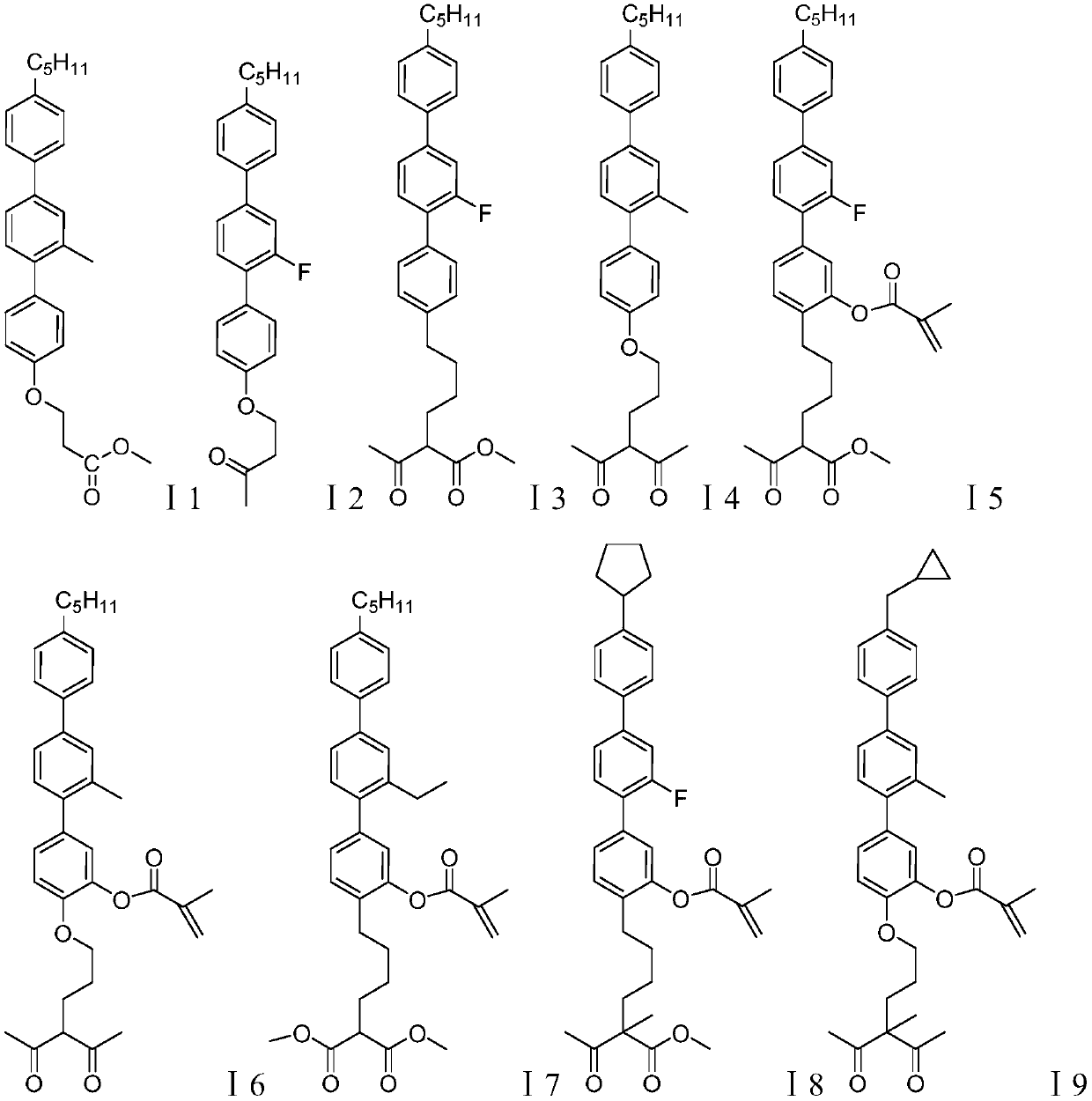

Embodiment 1

[0173]

[0174] step 1

[0175]

[0176] Add 38.2g (0.10mol) of (1-a), 0.12mol of triphenylphosphine, and 0.12mol of imidazole into a 1L three-neck flask, add 500ml of dichloromethane, stir to dissolve, and lower the temperature. At 0°C, under the protection of nitrogen, 17.6 g (0.11 mol) of liquid bromine was added dropwise, the reaction was exothermic, the protective gas was removed, and the addition was completed in about 30 minutes, and then stirred at room temperature for 2 hours after the addition. Add sodium bisulfite aqueous solution dropwise to the reaction system to quench the reaction, wash with water, dry, and concentrate to obtain a viscous solid, which is dissolved by adding 2 times petroleum ether, and the clear liquid is passed through a silica gel column, washed with petroleum ether, concentrated and the net solvent is anhydrous Recrystallized from ethanol to obtain 35.5g of white crystals (1-b), GC: 99.2%, yield: 80%

[0177] step 2

[0178]

[017...

Embodiment 2

[0181]

[0182] step 1

[0183]

[0184] Synthetic method and reaction conditions refer to Step 1 of Example 1, and compound (2-b) can be prepared by those skilled in the art.

[0185] step 2

[0186]

[0187] For the synthesis method and reaction conditions, refer to Step 2 of Example 1, and compound I14 can be prepared by those skilled in the art.

Embodiment 3

[0189]

[0190] step 1

[0191]

[0192] Synthesis method, reaction conditions refer to step 1 of Example 1, those skilled in the art can prepare compound (3-b)

[0193] step 2

[0194]

[0195] For the synthesis method and reaction conditions, refer to Step 2 of Example 1, and compound I26 can be prepared by those skilled in the art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com