Thin-layer surface-flowing wastewater treatment carrier, and wastewater treatment and thallus recovery system and method

A wastewater treatment and surface flow technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, biomass post-treatment, etc., can solve the problems of slow metabolism of pollutants, loss of bacterial cells, erosion and shedding, etc., to achieve Strengthen photosynthetic heterotrophic metabolism to remove sewage pollutants, strengthen film growth, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

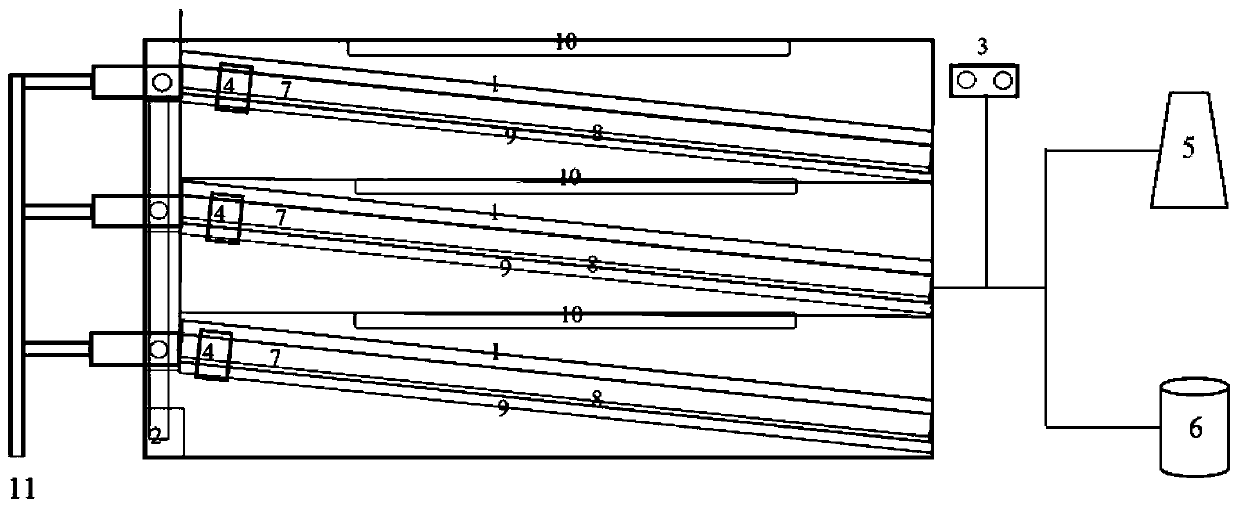

Method used

Image

Examples

Embodiment 1

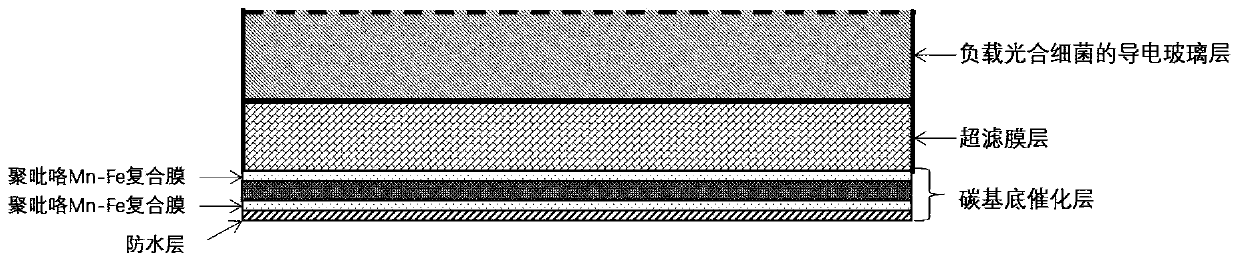

[0058] (1) Preparation of conductive glass with nanohole array on the surface

[0059] Through laser surface etching technology, a nano-hole array is formed on the surface of the conductive glass layer. The etching parameters are: hole spacing 100nm, hole diameter 80nm, hole depth 10nm, and a conductive glass with a nano-hole array on the surface is obtained. ;

[0060] (2) Preparation of carbon-based catalytic layer

[0061] ①Nano-Mn with a particle size of 10nm 3 o 4 , nano-Fe with a particle size of 10nm 3 o 4 According to the mass ratio of 1:2, add it into the 1mol / L potassium chloride electrolyte solution, and sonicate for 30 minutes;

[0062] 2. Under the condition of isolating the air, add pyrrole monomer in the reaction system of step (1), and continue to stir for 60 min; wherein, the consumption of pyrrole is 0.1% of the reaction system volume of step (1);

[0063] ③The carbon paper is immersed in the reaction system of step (2) as an electrode, and then a 0.8V ...

Embodiment 2

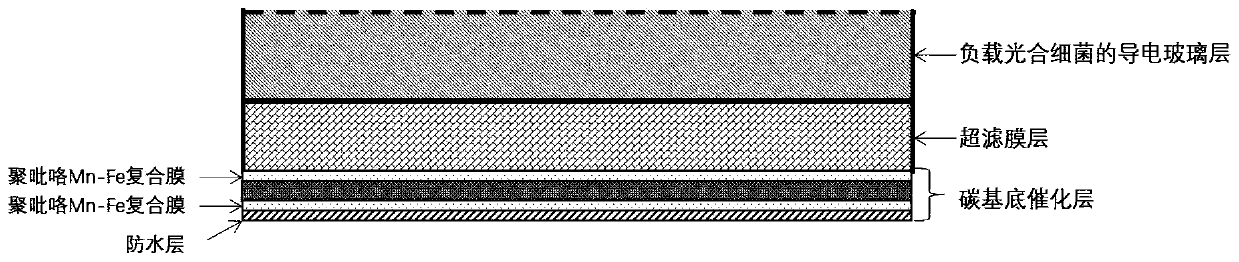

[0067] (1) Preparation of conductive glass with nanohole array on the surface

[0068] Through laser surface etching technology, a nano-hole array is formed on the surface of the conductive glass layer. The etching parameters are: the hole spacing is 20nm, the hole diameter is 30nm, and the hole depth is 50nm, and the conductive glass with the nano-hole array on the surface is obtained. ;

[0069] (2) Preparation of carbon-based catalytic layer

[0070] ①Nano-Mn with a particle size of 100nm 3 o 4 , Nano-Fe with a particle size of 100nm 3 o 4 According to the mass ratio of 1:5, add it into 1mol / L potassium chloride electrolyte solution, and ultrasonicate for 60min;

[0071] 2. Under the condition of cutting off air, add pyrrole monomer in the reaction system of step (1), continue to stir for 30min; Wherein, the consumption of pyrrole is 1% of the reaction system volume of step (1);

[0072] ③ carbon paper is immersed in the reaction system of step (2) as an electrode, and ...

Embodiment 3

[0076] (1) Preparation of conductive glass with nanohole array on the surface

[0077] Through laser surface etching technology, a nano-hole array is formed on the surface of the conductive glass layer. The etching parameters are: hole spacing 50nm, hole diameter 40nm, hole depth 40nm, and a conductive glass with a nano-hole array on the surface is obtained. ;

[0078] (2) Preparation of carbon-based catalytic layer

[0079] ①Nano-Mn with a particle size of 60nm 3 o 4 , Nano-Fe with a particle size of 60nm 3 o 4 According to the mass ratio of 1:3, add it into the 1mol / L potassium chloride electrolyte solution, and sonicate for 45 minutes;

[0080] 2. Under the condition of cutting off the air, add pyrrole monomer in the reaction system of step (1), and continue to stir for 45min; wherein, the consumption of pyrrole is 0.5% of the reaction system volume of step (1);

[0081] ③ carbon paper is immersed in the reaction system of step (2) as an electrode, and then a 1.0V con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com