Tool condition monitoring method based on ELM-SDAE algorithm

A tool and state technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of long time consumption and easy to fall into local optimum, so as to reduce production costs, reduce the dependence on machine tool operators' experience, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

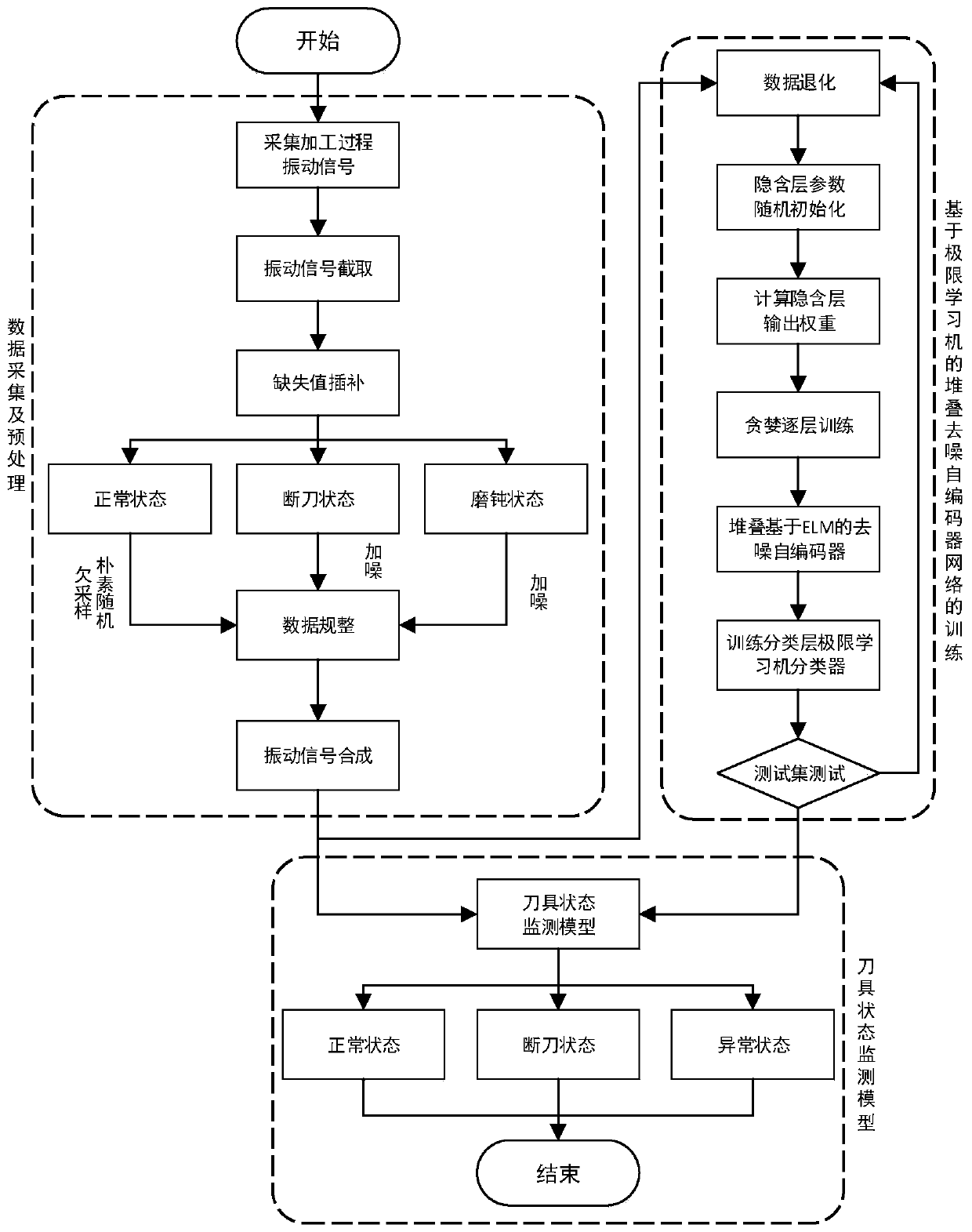

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solution and beneficial effects of the present invention clearer, the present invention will be described in detail below in combination with specific implementations of deep-hole boring tool state monitoring and with reference to the accompanying drawings. This embodiment is carried out on the premise of the technical solution of the present invention, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

[0046] Taking a horizontal deep hole boring machine as an example to process a deep hole, the embodiment of the present invention will be described in detail.

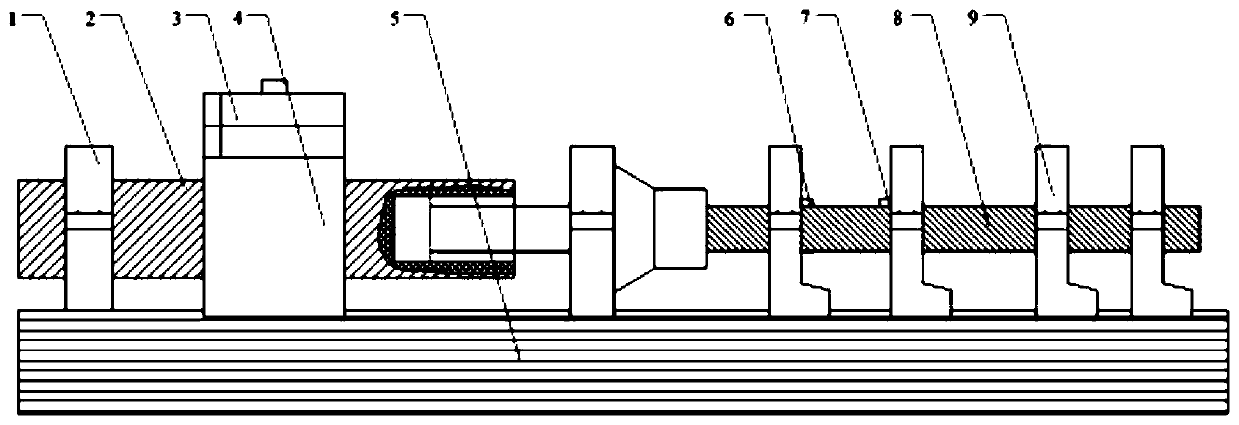

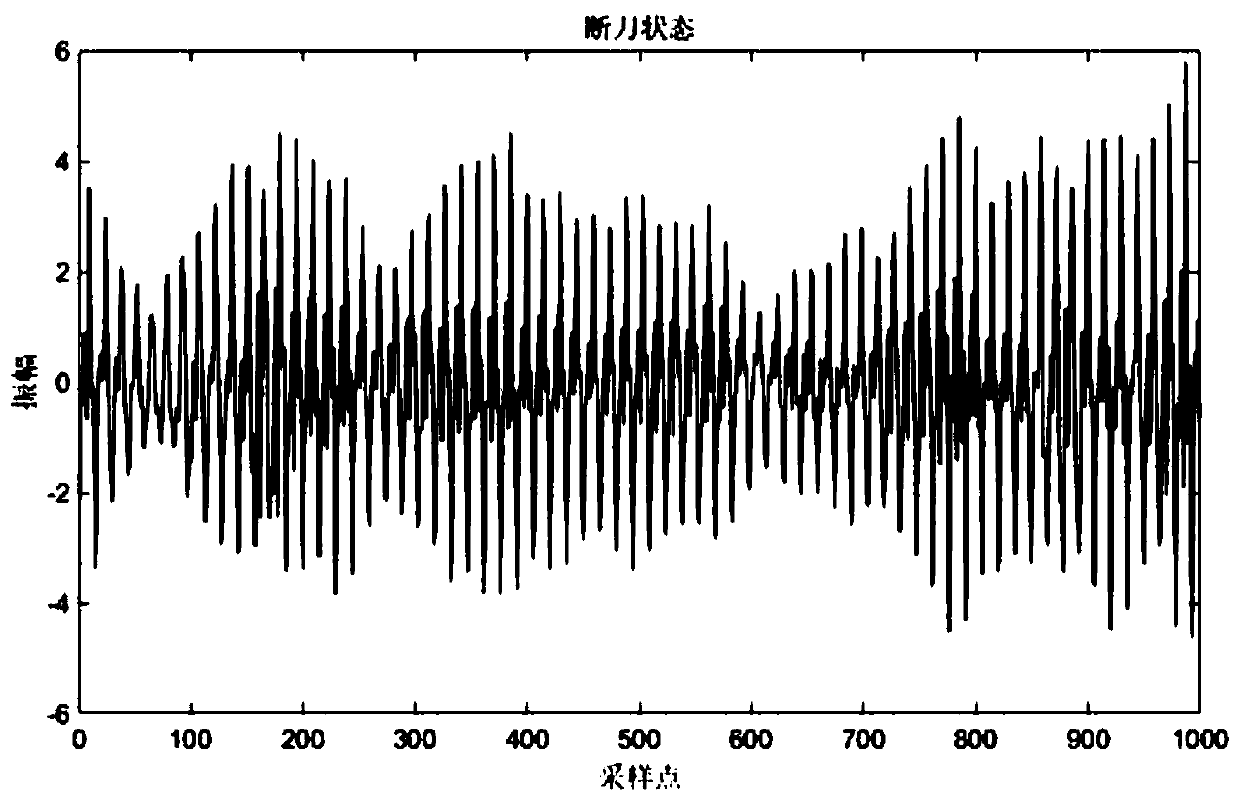

[0047] The first step, vibration signal acquisition during deep hole boring

[0048] Adsorb the #1 three-direction acceleration sensor 6 and #2 three-direction acceleration sensor 7 on the side of the bearing bush of the tool bar cage of the deep hole boring machine thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com