Follow-up tilting-head type big-tapered wire cutting device

A technology of wire cutting and large taper, which is applied in the field of follow-up swing head type large taper wire cutting device, which can solve the problems of increasing the weight of the upper cantilever cantilever, changing the tension of the electrode wire, and easily reducing the processing accuracy, etc., to achieve weight reduction , Improve the effect of accuracy, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

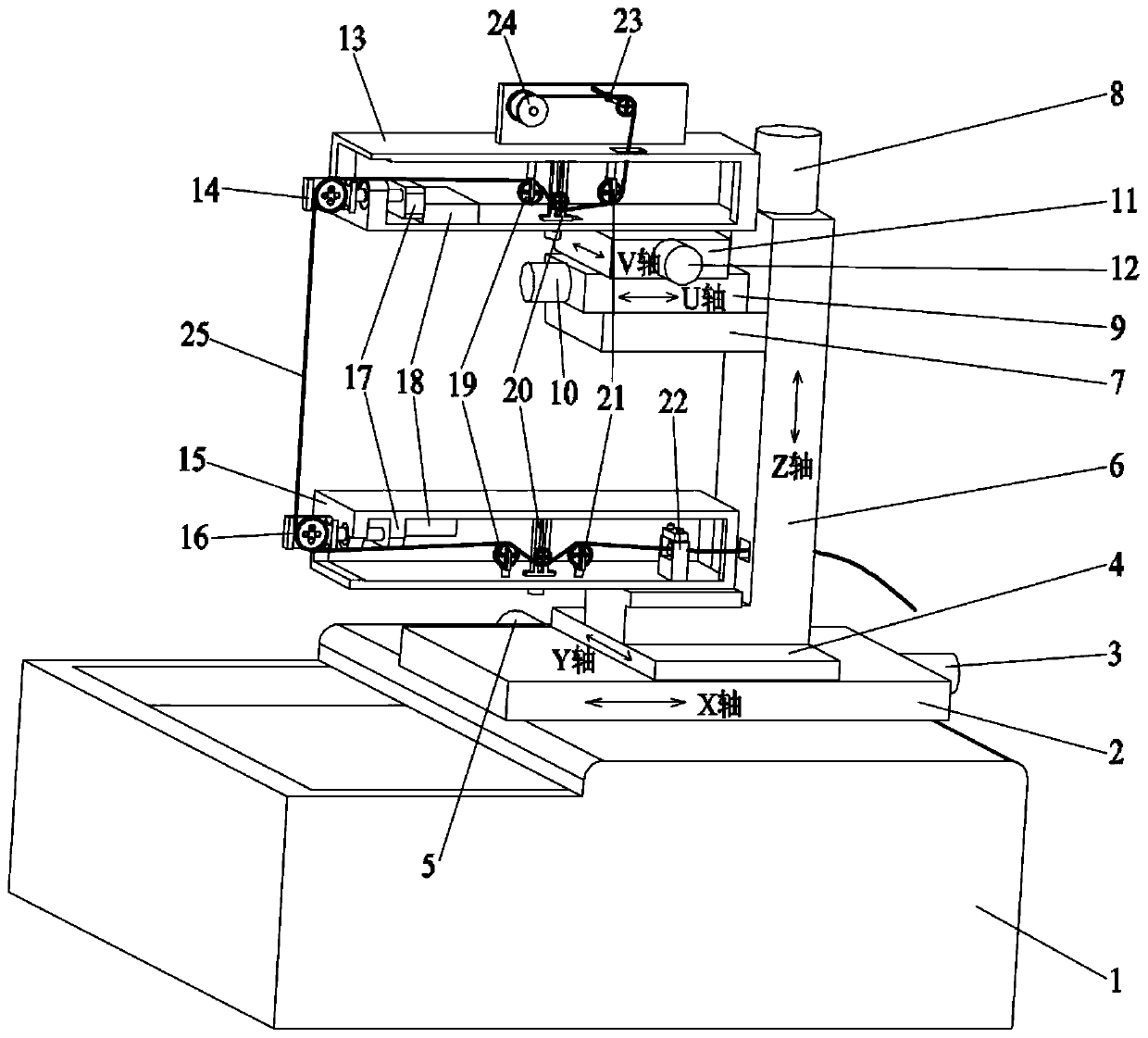

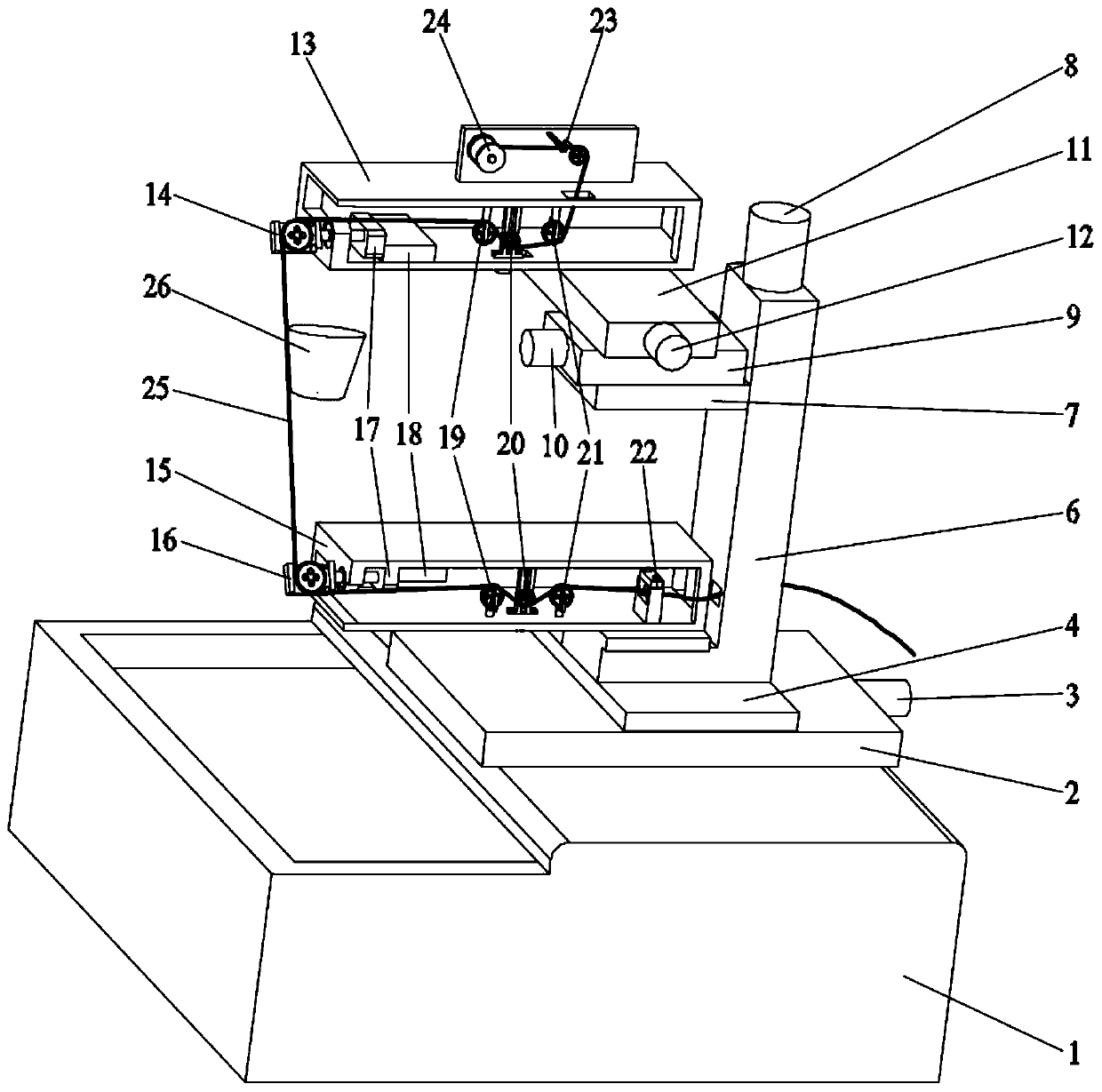

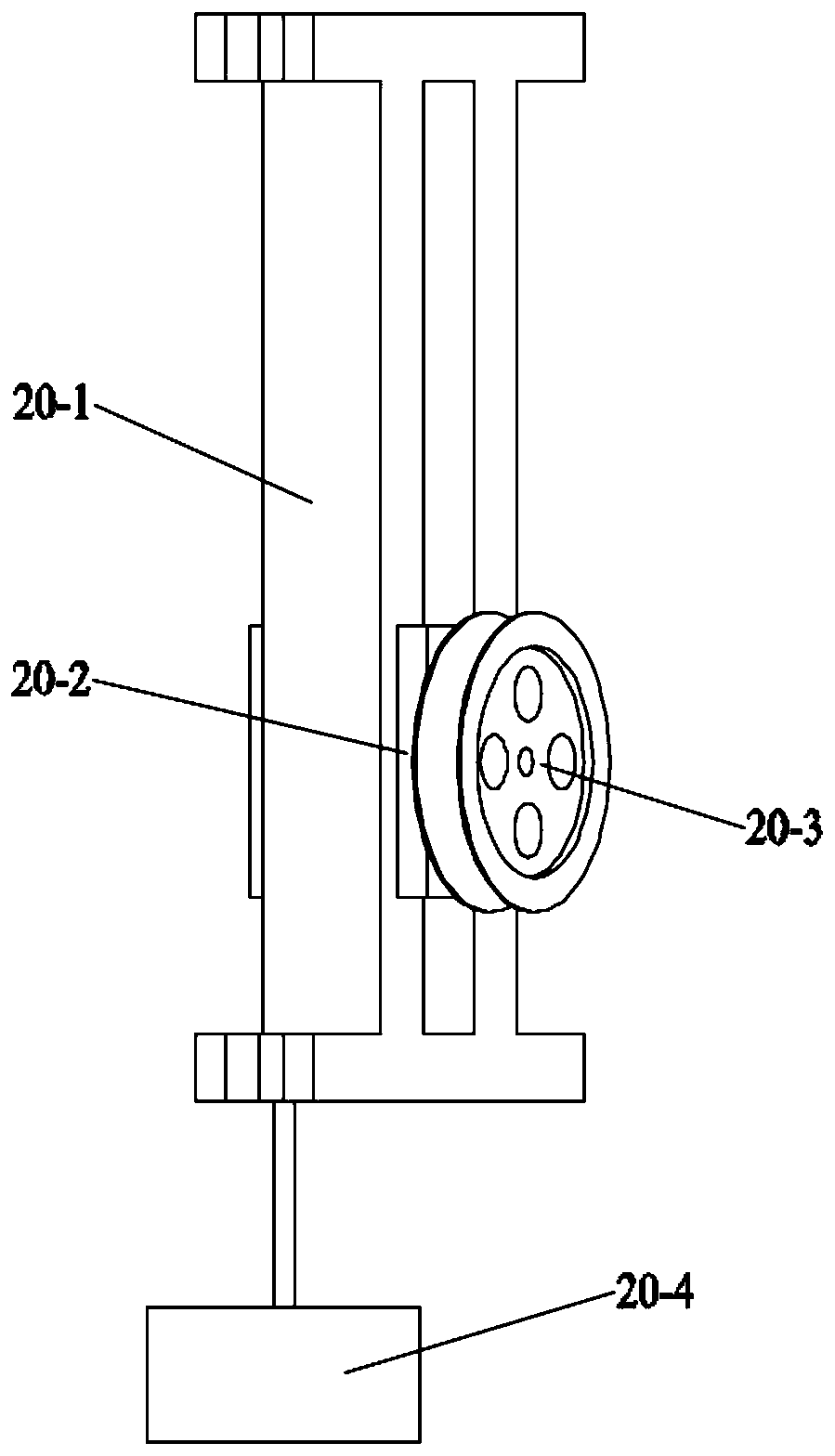

[0042] to combine figure 1 with figure 2 As shown, a follow-up swing head type large-taper wire cutting device in this embodiment includes a bed 1, an X-axis table 2, an X-axis driving mechanism 3, a Y-axis table 4, a Y-axis driving mechanism 5, and a spindle 6. Z-axis table 7, Z-axis drive mechanism 8, U-axis table 9, U-axis drive mechanism 10, V-axis table 11, V-axis drive mechanism 12, upper mechanical arm 13, upper swing head 14, lower mechanical The arm 15, the lower swing head 16, the electrode wire 25 and the wire feeding mechanism, the bed 1 is used to support the whole wire cutting device, the X-axis workbench 2 is installed on the bed 1 through the X-axis drive mechanism 3, and the Y-axis workbench 4 passes through The Y-axis driving mechanism 5 is installed on the X-axis table 2, the main shaft 6 is vertically installed on the Y-axis table 4, the lower mechanical arm 15 is fixedly installed on the lower end of the main shaft 6 or on the Y-axis table 4, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com