Axle tube part straightening device and process method

A technology for parts and shaft tubes, which is applied in the field of straightening devices for shaft and tube parts, can solve the problems of inability to straighten stepped shafts and surface quality defects, and achieve the effects of reduced straightening costs, high straightening success rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with example the present invention is described in further detail:

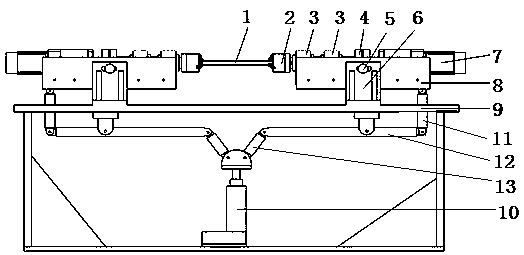

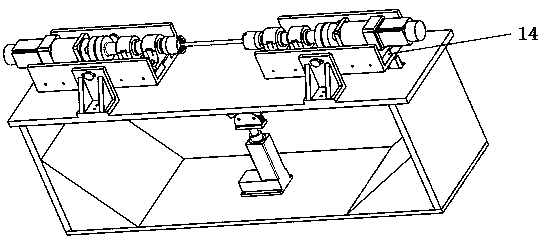

[0034] like Figure 1-3 As shown, a straightening device for shaft and tube parts is characterized in that it includes two symmetrical straightening mechanisms installed on the workbench 9, a link mechanism for transmitting motion and amplifying force, and a connecting rod mechanism for providing power. The hydraulic system and the numerical control system used for control and command; the straightening mechanism is installed on the upper part of the workbench 9; The lower end is hinged; the connecting rod mechanism is connected with the hydraulic system; the hydraulic system and the motors 7 in the two sets of straightening mechanisms are all connected with the numerical control system.

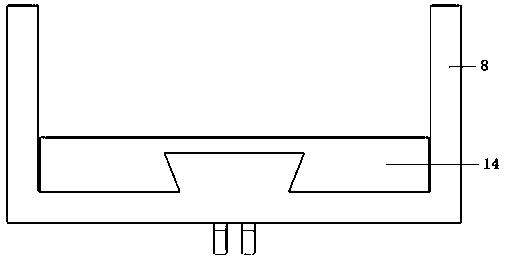

[0035]The straightening mechanism includes a chuck 2, two sets of bearing housing assemblies 3, a coupling 4, a pin shaft 5, two L-shaped plates with reinforcing ribs 6, a motor 7, and a U-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com