Strong mixing reactor

A technology for mixing reactors and reactors, which is applied in the field of reactors, can solve the problems of increasing the complexity of the process flow, the structure of the reactors, the loss of stirring paddles, etc., so as to improve the efficiency of the reactors, improve the space utilization rate, and improve the mixing of each phase. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

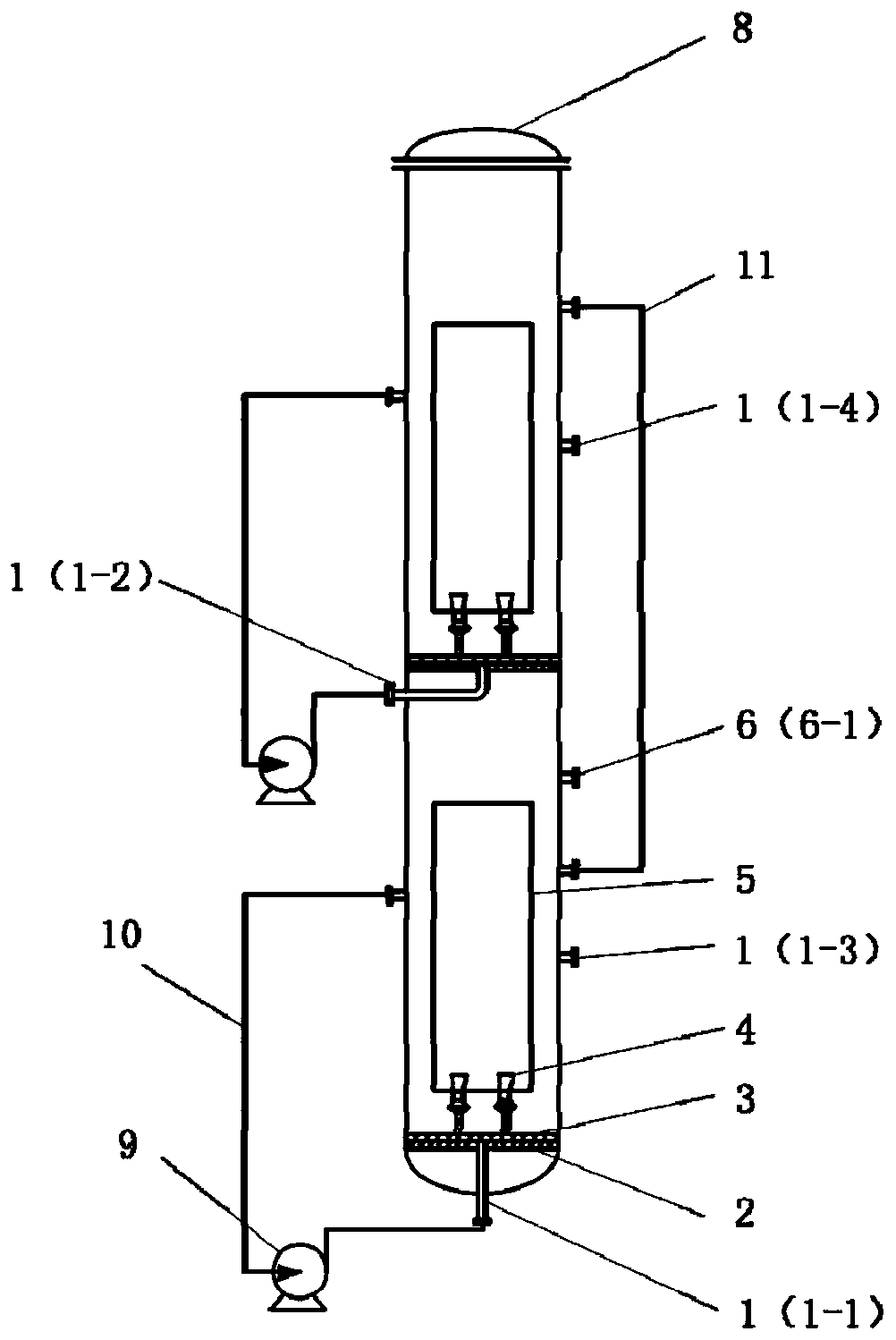

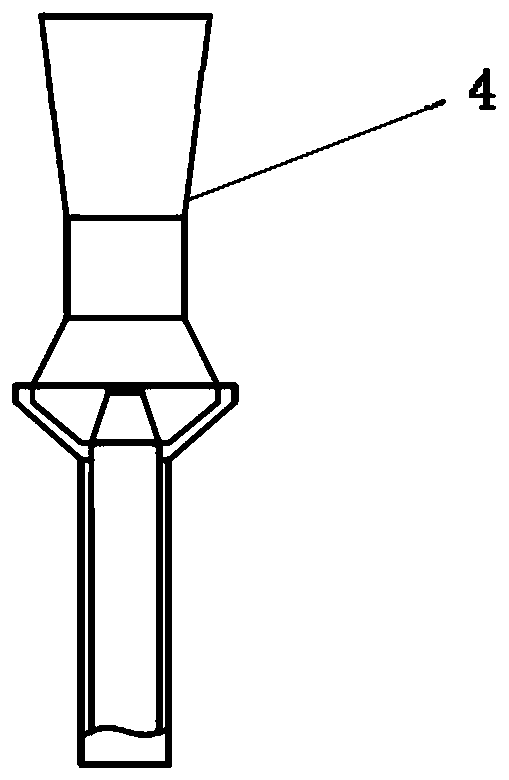

[0036] figure 1 and figure 2It is a schematic diagram of the implementation structure of a liquid-liquid multi-stage strong mixing reactor. In the reactor of this embodiment, the reactor is two stages, and the reactor is the first stage and the second stage successively from top to bottom; The reactor comprises a reactor liquid inlet (1), a liquid outlet (6), and the reactor Bed body (8), inner sleeve (5), circulation pipeline (10) and circulation pump (9) installed on the periphery of the reactor. The substrates (2) of the reactors at all levels are arranged with liquid distributors (3), and the liquid distributors (3) are equipped with single or multiple Venturi mixed flow nozzles (4); the liquid distributors (3) are controlled by the liquid distributors It is composed of one or more liquid distribution pipes (12); one end of the liquid distribution pipe is connected with the hole on the main pipe of the liquid distributor, and the other end is connected with the Venturi ...

Embodiment 2

[0043] Image 6 It is a schematic diagram of the implementation structure of the liquid-solid and liquid-liquid-solid system multi-stage strong mixing reactor. In the reactor of this embodiment, the reactor has two stages, and the reactor is the first stage and the second stage from top to bottom; The same; in addition, the circulating liquid formed in the inner sleeve and between the annulus drives the solid catalyst particles to evenly suspend. The liquid-solid fluid in each stage reactor is separated from solid and liquid through the baffle plate (13) on the upper part of the reactor; part of the clarified liquid enters the circulation pipeline (10) of the stage, and part of it passes through the liquid outlet (6) or stage The intermediate overflow pipe flows out of the reactor at this stage; the solid catalyst returns to the circulation area of the reactor at this stage through the arcuate through hole formed by the baffle plate and the reactor bed due to the gravity se...

Embodiment 3

[0047] Figure 8 It is a schematic diagram of the implementation structure of the gas-liquid and gas-liquid-liquid system multi-stage strongly mixed parallel flow reactor. In the reactor of this embodiment, the reactor is two stages, and the reactor is the first stage and the second stage successively from top to bottom; the reactor comprises a reactor liquid inlet (1), a gas inlet (15), and a liquid outlet (6), a reactor bed body (8), an inner sleeve (5), a circulation pipeline (10) and a circulation pump (9) installed on the periphery of the reactor. Liquid distributors (3) and gas distributors (16) are arranged at the bottom of the reactors at all levels.

[0048] In the reactor of this embodiment, the liquid circulation in the stage of each stage reactor is the same as that of Embodiment 1; in addition, the bubbles flowing out from the gas distributor (16) further promote the internal circulation flow formed in the inner sleeve and between the annulus , so as to achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com