Cold-resistant water-based fire extinguishing agent suitable for -30 DEG C, and preparation method thereof

A technology of fire extinguishing agent and water system, applied in fire prevention equipment, etc., can solve the problems of ineffective reduction of the temperature of combustion objects, reduction of fire extinguishing efficiency, large surface tension value, etc., and achieves strong recombustion resistance, short degradation time and fast fire extinguishing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a cold-resistant water-based fire extinguishing agent suitable for -30°C as claimed in claim 3, characterized in that it comprises the following steps:

[0024] (1) Add 8% of ammonium dihydrogen phosphate, 8% of diammonium hydrogen phosphate, 15% of ethylene glycol and 4% of sodium bicarbonate successively by weight percentage in the synthesis reactor, and the stirring speed of the reactor setting is 1800r / min, the temperature is 35°C, and the synthesis is stirred for 30 min;

[0025] (2) Adjust the rotating speed of the reactor to be 45r / min, and the temperature is 30°C, then continue to add 2% fluorocarbon surfactant and 810% alkyl glycoside APG in sequence, and the stirring synthesis time is 90min, and the stirring synthesis time is 90min;

[0026] (3) On the basis of step (2), add the remaining amount of water and stir for 4 hours, then the central control detects, and after standing at room temperature for 2 hours, the finished product is co...

Embodiment 2

[0029] A method for preparing a cold-resistant water-based fire extinguishing agent suitable for -30°C as claimed in claim 3, characterized in that it comprises the following steps:

[0030] (1) Add 10% ammonium dihydrogen phosphate, dihydrogen phosphate 10%, ethylene glycol 18% and sodium bicarbonate 6% successively by weight percentage in the synthesis reactor, and the stirring speed of the reactor is set to 1800r / min , the temperature is 35 ~ 40 ° C, stirring for 30 minutes;

[0031] (2) Adjust the rotating speed of the reaction kettle to be 45r / min, and the temperature is 32°C, then continue to add 3% fluorocarbon surfactant and alkyl glycoside APG8 in sequence, and stir for 90 minutes to synthesize;

[0032] (3) On the basis of step (2), add the remaining amount of water and stir for 4 hours, then the central control detects, and after standing at room temperature for 2 hours, the finished product is completed;

[0033] (4) Settling for 10 days (according to GB15308-2006...

Embodiment 3

[0035] A method for preparing a cold-resistant water-based fire extinguishing agent suitable for -30°C as claimed in claim 3, characterized in that it comprises the following steps:

[0036] (1) Add 10% of ammonium dihydrogen phosphate, 10% of diammonium hydrogen phosphate, 20% of antifreeze and 8% of sodium bicarbonate successively by weight percentage in the synthesis reaction kettle, and the stirring speed of the reaction kettle is set to be 1800r / min, the temperature is 40°C, and the synthesis is stirred for 30 min;

[0037] (2) Adjust the rotating speed of the reactor to be 45r / min, and the temperature is 35°C, then continue to put in 5% fluorocarbon surfactant and 810% alkyl glycoside APG in sequence, and stir for 90 minutes to synthesize;

[0038] (3) On the basis of step (2), add the remaining amount of water and stir for 4 hours, then the central control detects, and after standing at room temperature for 2 hours, the finished product is completed;

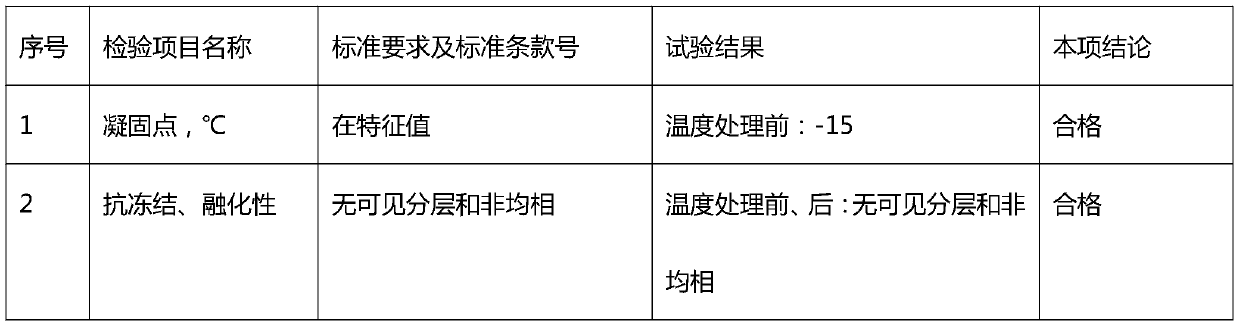

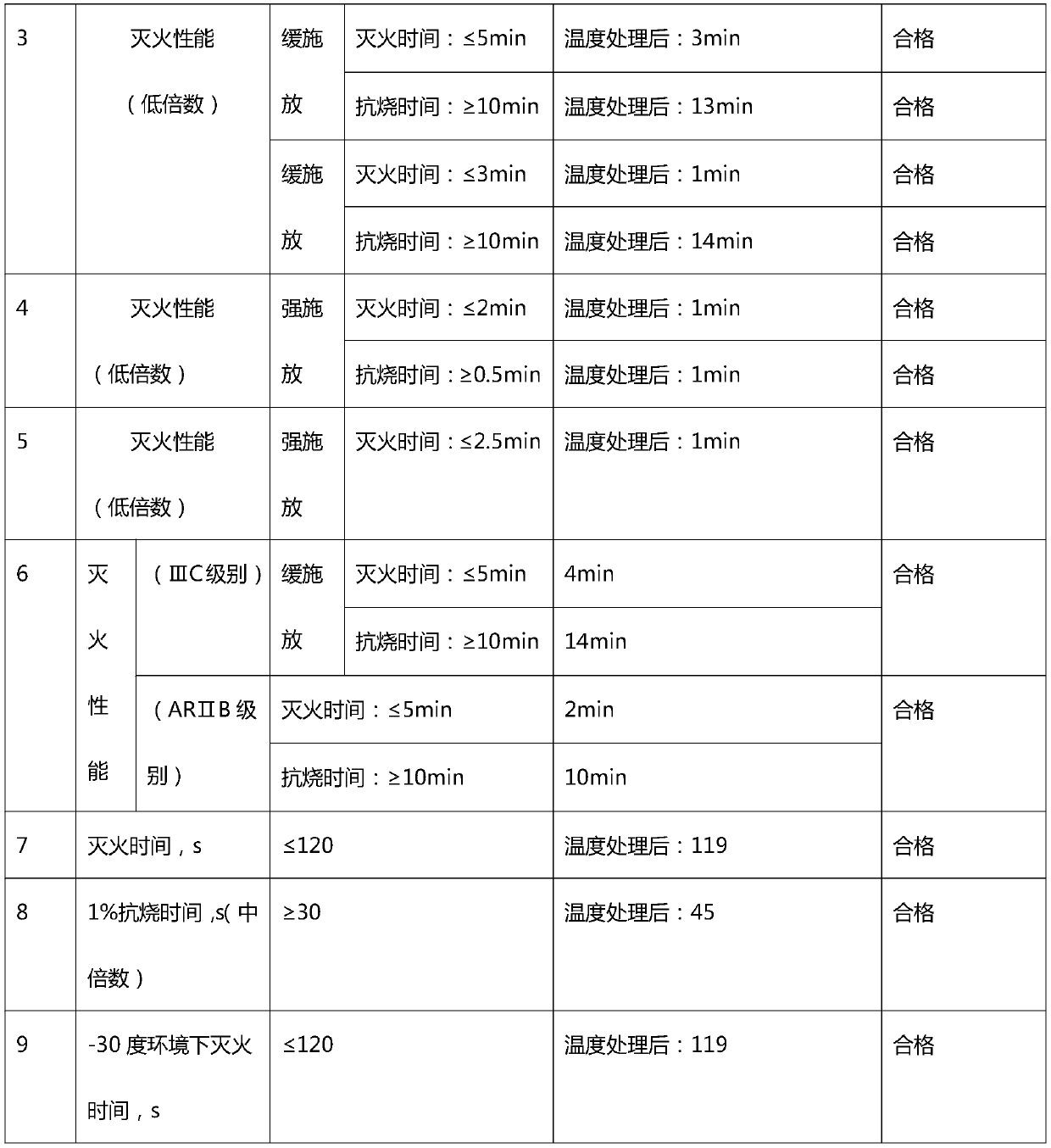

[0039] (4) Sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com