Hydrogel wound dressing and preparation method thereof

A wound dressing and hydrogel technology, applied in the field of medical dressings and their preparation, can solve the problems of the influence of the gas permeability of the dressing, unfavorable wound breathing, and discomfort for patients, and achieves reduced coating area, shortened preparation time, and excellent comfort. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

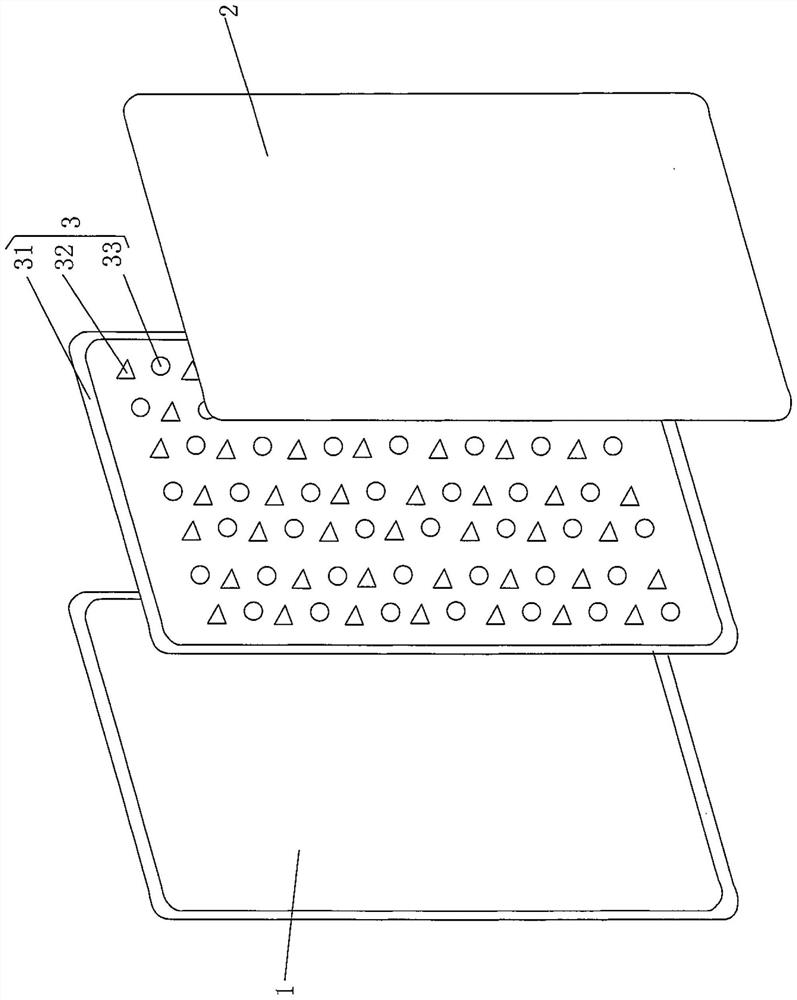

[0023] prepared by figure 1 The illustrated hydrogel wound dressing comprises the following steps:

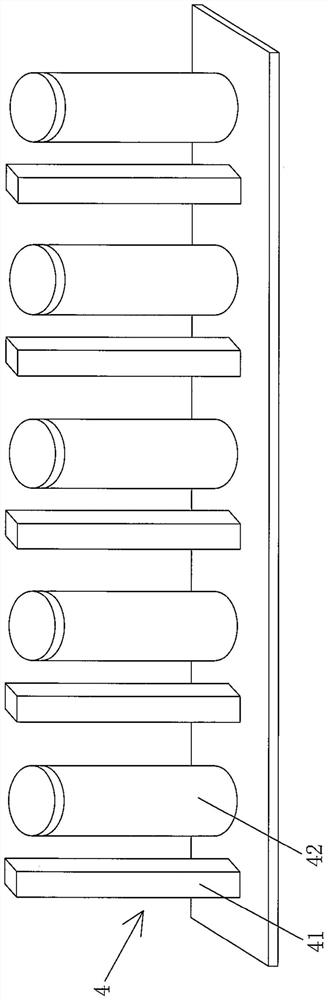

[0024] A) Prepare the core layer 3, first fill the first raw material as the floating-point adhesive layer 32 and the second raw material as the floating-point liquid-absorbing layer 33 into the image 3 In the two containers of the spraying machine of the shown matrix shower head 4, then by the matrix shower head 4, the aforementioned first raw material and the second raw material are sprayed onto one side surface of the backing layer 31 in a point-like spraying mode, and then the power is preferably 50-1000W, preferably 200-600W, preferably 400W (this embodiment selects 400W) UV lamp irradiation molding, specifically by the backing layer 31 carrying the floating point adhesive layer 32 and the floating point shape The liquid-absorbing layer 33 is preferably 10-30m / min, preferably 12-18m / min, preferably 15m / min (the present embodiment is 15m / min) speed away from the ultraviol...

Embodiment 2

[0027] prepared by figure 1 The illustrated hydrogel wound dressing comprises the following steps:

[0028] A) Prepare the core layer 3, first fill the first raw material as the floating-point adhesive layer 32 and the second raw material as the floating-point liquid-absorbing layer 33 into the image 3 In the two containers of the spraying machine of shown matrix shower head 4, then by matrix shower head 4, aforesaid first raw material and second raw material are sprayed onto one side surface of backing layer 31 with dotted spraying mode, then on backing layer 31, together with the floating-point adhesive layer 32 and the floating-point liquid-absorbing layer 33, pass through the drying tunnel at a temperature of 70°C at a speed of 20m / min, so as to be combined with the backing layer 31 together with the molding The floating-point adhesive layer 32 and the floating-point liquid-absorbing layer 33 on one side surface of 31 are composed of figure 1 and figure 2For the core ...

Embodiment 3

[0031] prepared by figure 1 The illustrated hydrogel wound dressing comprises the following steps:

[0032] A) Prepare the core layer 3, first fill the first raw material as the floating-point adhesive layer 32 and the second raw material as the floating-point liquid-absorbing layer 33 into the image 3 In the two containers of the spraying machine of shown matrix shower head 4, then by matrix shower head 4, aforesaid first raw material and second raw material are sprayed onto one side surface of backing layer 31 with dotted spraying mode, then on backing layer 31, together with the floating-point adhesive layer 32 and the floating-point liquid-absorbing layer 33, pass through the drying tunnel at a temperature of 30°C at a speed of 30m / min, thereby being bonded to the backing layer by the backing layer 31 together with molding The floating-point adhesive layer 32 and the floating-point liquid-absorbing layer 33 on one side surface of 31 are composed of figure 1 and figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com