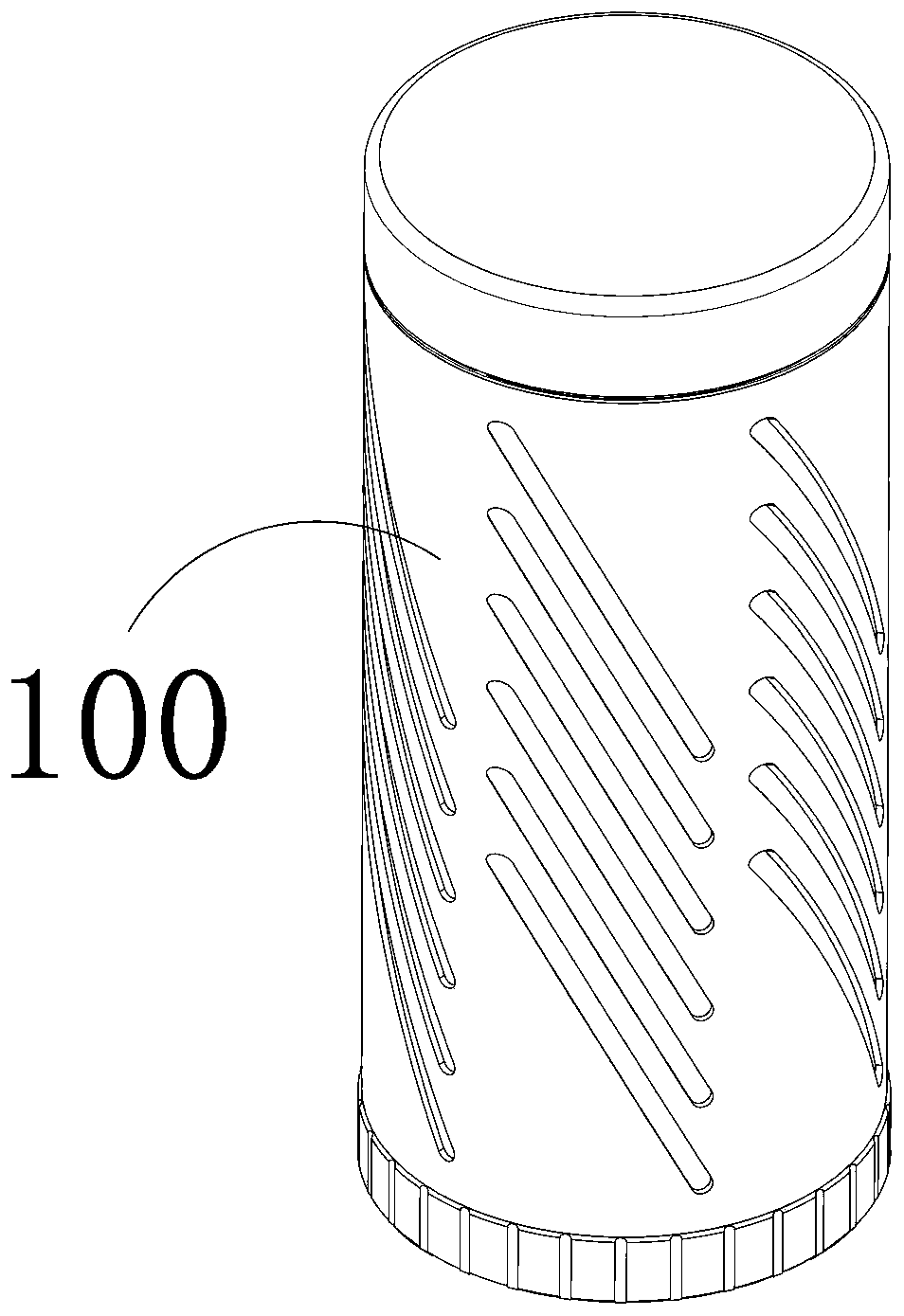

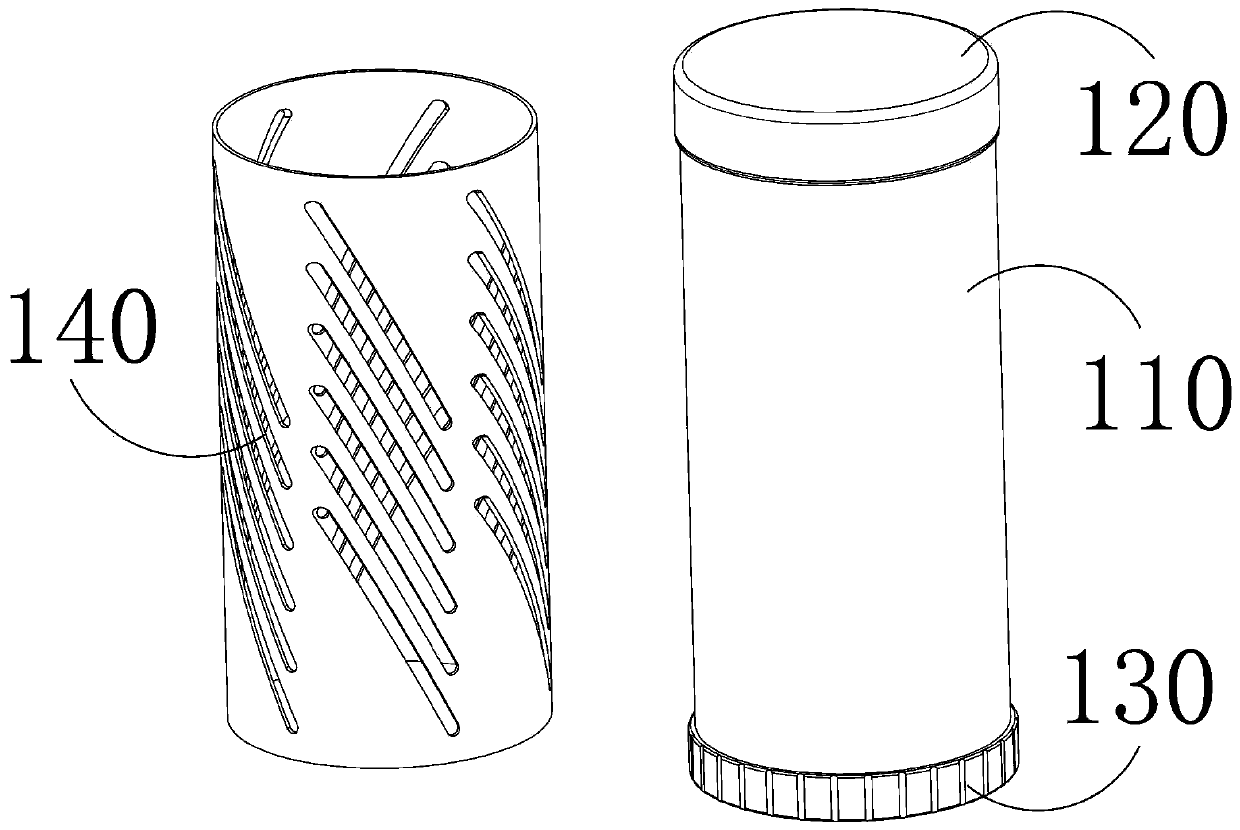

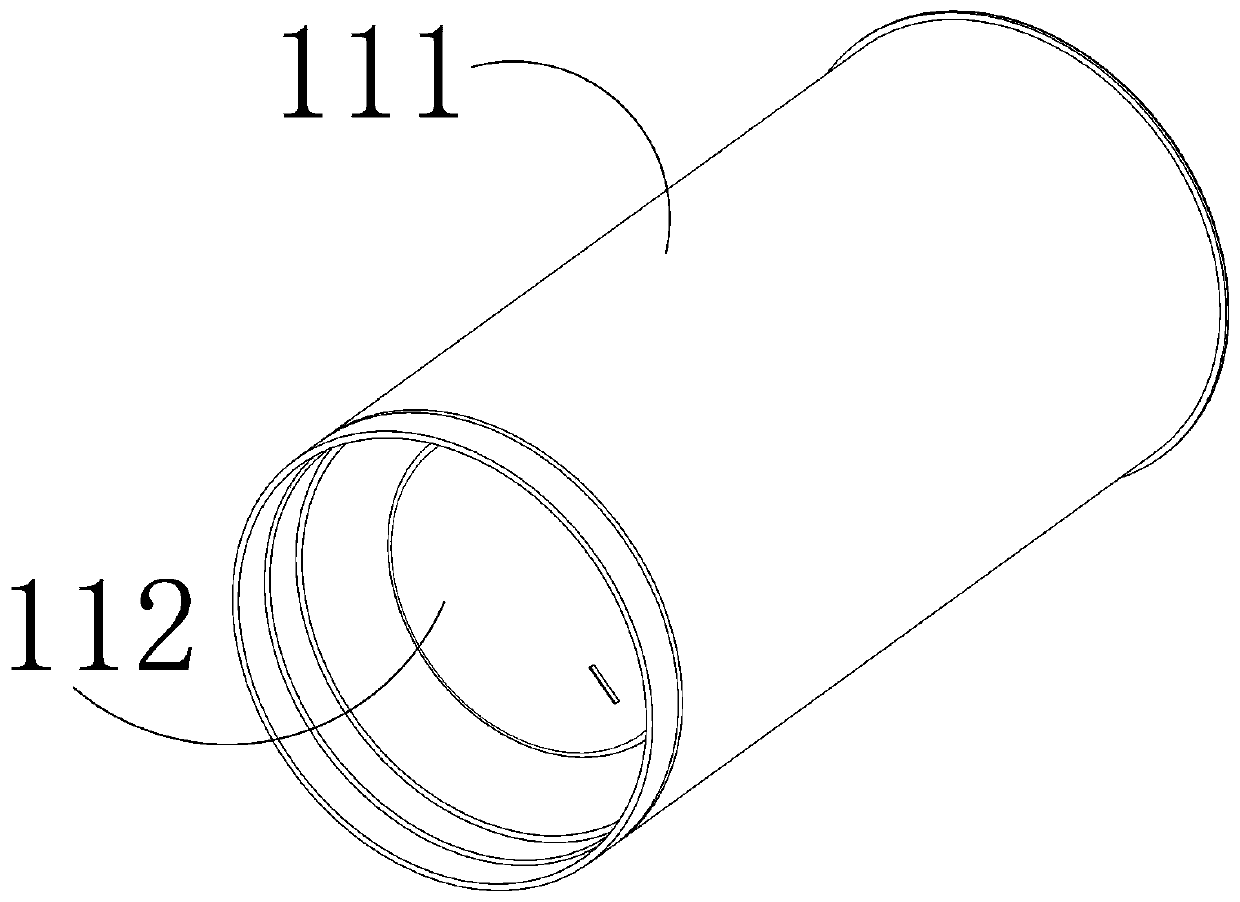

Switching assembly used for temperature control of vacuum cup

A technology for switching components and thermos cups, which is applied in the field of living utensils, and can solve the problems of reducing the thermal insulation effect of thermos cups, inconvenient users, and unhygienic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The advantage of the present invention compared with the existing thermal insulation water cup is that it can stir the liquid in the water cup, and can also carry out heat dissipation and cooling treatment on the liquid in the water cup; Compared with the motor driving method in the prior art, this thermos water cup does not need to open holes at the bottom of the inner tank cavity, and there will be no electric leakage accidents and battery leakage affecting health; during the heat dissipation and cooling process, The heat preservation area tends to zero and the water cup is switched from the heat preservation state to the heat dissipation state of the ordinary water cup. At the same time, the liquid is stirred by the stirring rod. The combination of the two can quickly dissipate heat and cool down the liquid in the water cup; in addition, stirring The device is equipped with a planetary speed-increasing structure, so the user can turn the rotating cover at a normal spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com