Hardware automatic test tool and test method based on Internet of Things

A technology of automatic testing and the Internet of Things, which is applied in the direction of services, measuring devices, electrical components, etc. based on specific environments, can solve problems such as inconvenient, labor-intensive and time-consuming, and improve accuracy, ensure consistency, and save The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

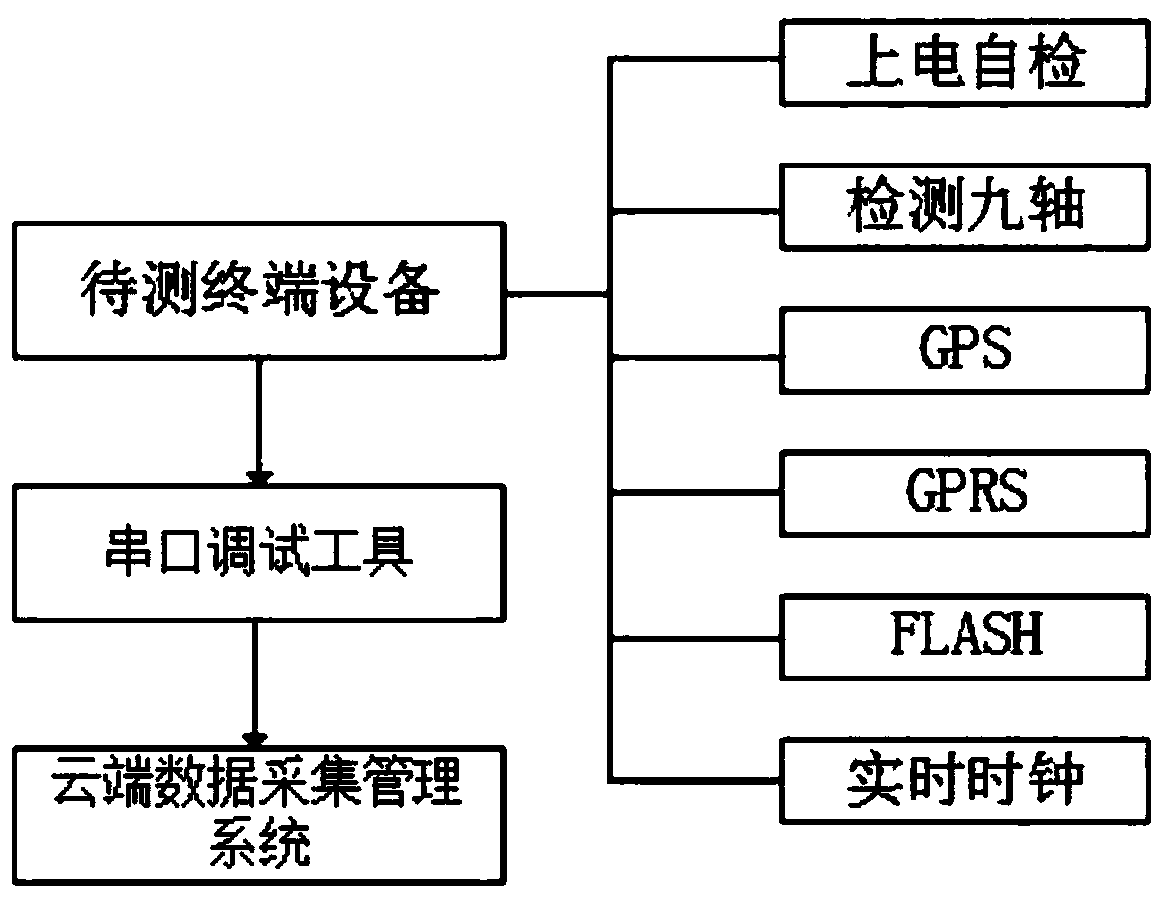

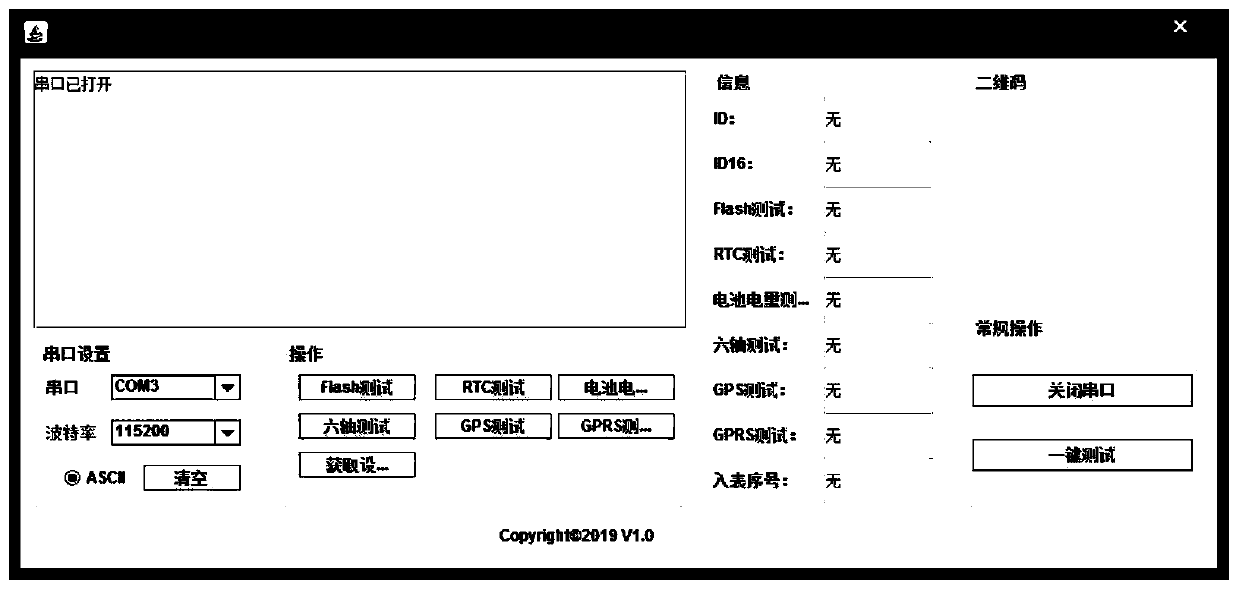

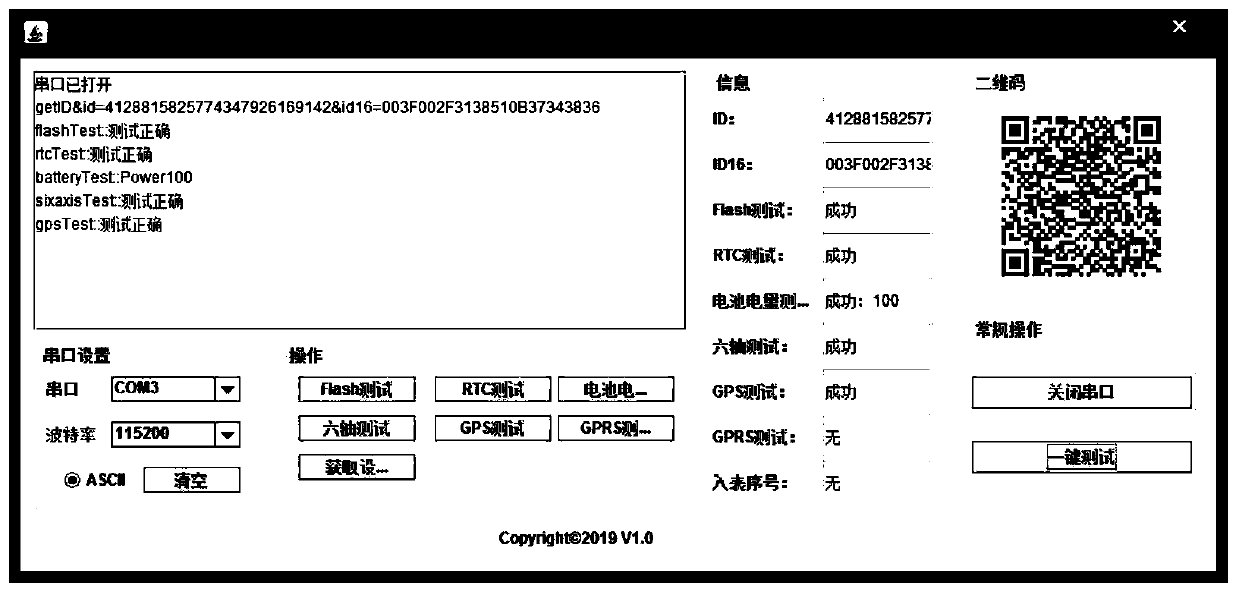

[0048] A hardware automatic testing tool based on the Internet of Things, including a testing device for terminal equipment to be tested, a serial port debugging tool and a cloud data acquisition management system.

[0049] The testing device for the terminal equipment to be tested uploads the physical information, the function test process and the test results of the terminal equipment to be tested to the serial port debugging tool.

[0050] The test device of the terminal equipment to be tested includes a power-on self-test module, a nine-axis detection module, a GPS module, a GPRS module, a FLASH module and a real-time clock module. Establish communication, realize the time setting in the test through the real-time clock.

[0051] After the terminal device under test passes the self-inspection, turn on the nine-axis and GPS power every minute to read the attitude information; according to the upload time interval, turn on the GPRS power, establish a link with the cloud data...

Embodiment 2

[0082] A hardware automatic testing method based on the Internet of Things, the method sets a test module on the terminal device to be tested, the test module obtains the driver program of the device communication protocol, and uploads the physical information, functional test process and test results of the terminal device to be tested to the serial debugging tool.

[0083] The test module includes power-on self-test module, nine-axis detection module, GPS module, GPRS module, FLASH module and real-time clock module. After the terminal equipment to be tested passes the self-test, turn on the nine-axis and GPS power every minute to read the attitude information ;According to the upload time interval, turn on the GPRS power supply, establish a link with the cloud platform, then push the data, receive the ACK returned by the cloud platform, and finally return the received ACK response signal to end this communication. After pushing the data, start the timeout detection. If you d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com