White LED light source with infrared band added in spectrum

A technology of LED light source and infrared band, applied in the field of white light LED light source, can solve the problems of insufficiency and lack of infrared band, and achieve the effect of no light spot and good uniformity of color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

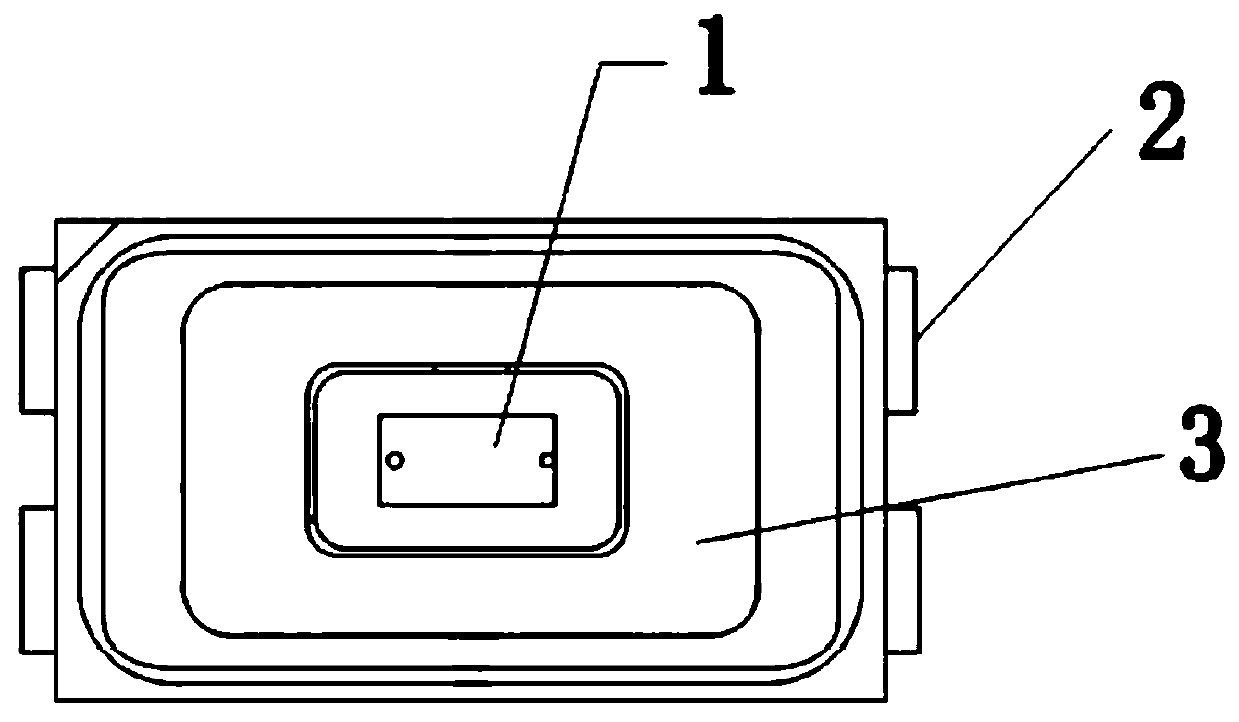

[0033] Such as figure 1 As shown, the white light SMD LED lamp bead of this embodiment includes an LED chip 1 , two electrodes 2 and an LED bracket 3 , and the two electrodes are respectively located at both ends of the LED bracket 3 for leading out the positive and negative poles of the LED chip 1 .

[0034] First, fix the chip 1 (a chip with a peak wavelength of 405nm in this embodiment) on the LED bracket 3, and connect the two ends of the chip to the two pole pieces at the bottom of the substrate through gold wires to conduct with the two electrodes 2.

[0035] Then, a certain ratio is prepared to contain infrared, red, green, and blue four-color fluorescent powder (infrared fluorescent powder (Y, Gd) of this embodiment) 3 Ga 5 o 12 : Cr, red phosphor: CaAlSi(ON )3 :Eu, green phosphor: β-SiAlON:Eu, blue phosphor: (Sr,Ba) 10 (PO 4 ) 6 Cl 2 :Eu) mixed colloid, stirred evenly, vacuum defoaming.

[0036] Further, the mixed colloid is uniformly coated on the LED chip, a...

Embodiment 2

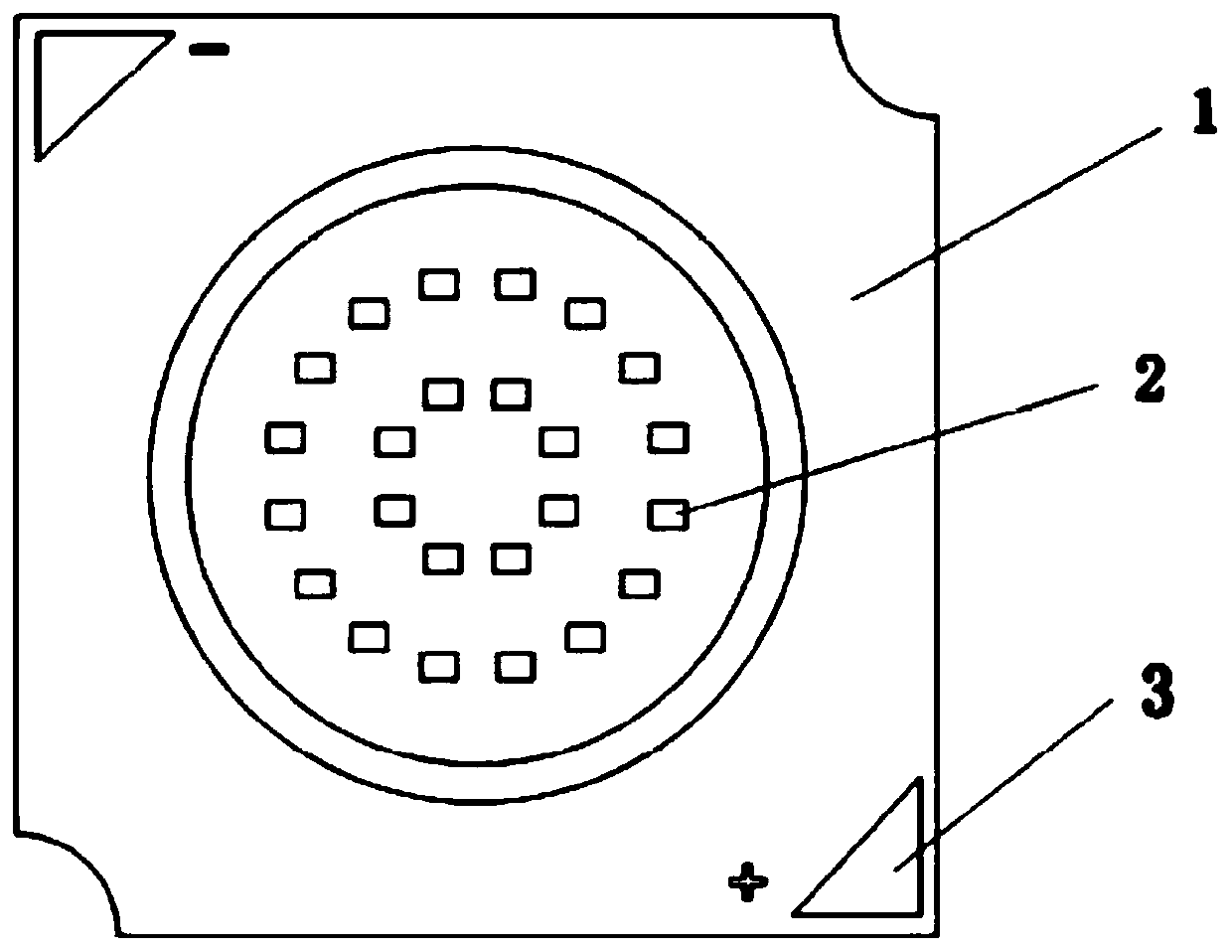

[0042] Such as image 3 As shown, the white light LED module of this embodiment includes an LED module bracket 1, an LED chip 2 and two electrodes 3, and the two electrodes are respectively located at two opposite corners of the LED module bracket 1 for leading out the positive side of the LED chip 2. negative electrode.

[0043] First, several chips 2 (chips with a peak wavelength of 405nm are used in this embodiment) are fixed on the LED module bracket 1, and the two ends of the chips are respectively connected to the two pole pieces at the bottom of the substrate through gold wires in a series-parallel manner, so as to be connected to the two electrode 3 to conduction.

[0044] Then, after damming and baking, a certain proportion is prepared to contain infrared, red, green, blue (infrared fluorescent powder in this embodiment: (Y, Gd) 3 Ga 5 o 12 : Cr, red phosphor: CaAlSi(ON )3 :Eu, green phosphor: β-SiAlON:Eu, blue phosphor: (Sr,Ba) 10 (PO 4 ) 6 Cl 2 :Eu) Mixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com